Replacement Of BLV10037 Hitch Downforce Hydraulic Kit

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:sales@hydraulic-cylinders.net

Manufacturer supplier exporter of hydraulic cylinders.

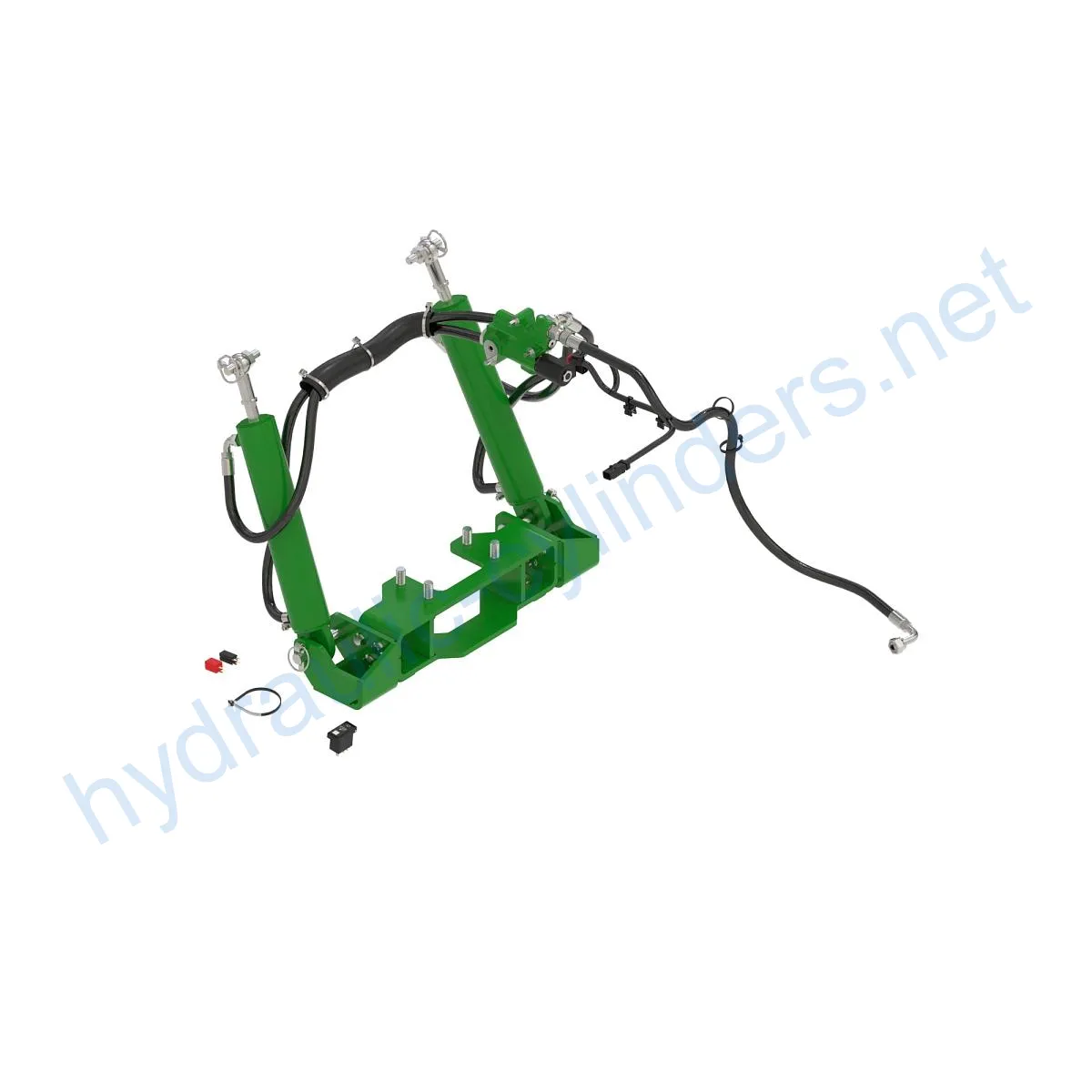

Replacement Of BLV10037 Hitch Downforce Hydraulic Kit

Replacement Of BLV10037 Hitch Downforce Hydraulic Kit is a hydraulic cylinder used as a replacement for damaged or worn out cylinders in John Deere tractors. It plays an important role in restoring the normal operating ability of equipment and ensuring its performance in various applications.

Specifications

- Weight: 60.677 lb

- Height: 6.5 in

- Width: 14.8 in

- Length: 18.5 in

Compatible Model

- 4044R

- 4049R

- 4052R

- 4066R

Features

Here are at least 5 features of Replacement Of BLV10037 Hitch Downforce Hydraulic Kit:

- Improves equipment performance: Replacing damaged or worn out hydraulic cylinders can restore the normal operating ability of equipment and ensure its performance in various applications.

- Enhances safety: Regularly replacing hydraulic cylinders can reduce safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

- Overload protection: New cylinder designs usually consider better overload protection mechanisms to enhance safety.

- Quick installation: Modern hydraulic cylinder designs usually consider easy installation and replacement, reducing downtime.

- Standardized components: Many hydraulic cylinders are standardized products, making it easier to obtain replacement parts in the market.

We can produce this product, our product can perfectly replace these hydraulic cylinders.

Applications

Replacement Of BLV10037 Hitch Downforce Hydraulic Kit has various applications in different equipment types. Here are 3 examples:

- Excavators: Hydraulic cylinders in excavator arms or buckets may become damaged due to long-term use or overload and need to be replaced to restore normal operation.

- Cranes: Hydraulic cylinders in crane boom are easily worn out in frequent lifting and lowering processes, requiring regular replacement to ensure safety.

- Tractors: Hydraulic cylinders in front-end loader of tractors may leak or perform poorly in continuous lifting and tilting operations, requiring replacement.

Applications Details

In excavators, hydraulic cylinders are used to control the movement of the arm or bucket, and they are often subjected to heavy loads and harsh environmental conditions. The cylinder may become damaged after prolonged use or overload, which can affect the efficiency and safety of the excavator. Regularly replacing the hydraulic cylinder can restore the normal operation of the excavator and ensure its performance.

In cranes, hydraulic cylinders are used to control the movement of the boom, and they are subjected to frequent lifting and lowering processes. The cylinder may wear out quickly due to the high intensity of use, which can pose a safety hazard. Regularly replacing the hydraulic cylinder can ensure the safety of the crane and its operators.

In tractors, hydraulic cylinders are used to control the movement of the front-end loader, and they are subjected to continuous lifting and tilting operations. The cylinder may leak or perform poorly over time, which can affect the efficiency and safety of the tractor. Regularly replacing the hydraulic cylinder can ensure the normal operation of the tractor and its loader.

Maintenance

Here are 3 common maintenance tasks:

- Regular inspection

- Proper lubrication

- Seal and calibration checks

It is important to provide proper guidance on aligning the cylinder during the installation process, recommend using appropriate installation brackets to secure the cylinder, and provide recommended check, repair, and replacement procedures to maximize the service life of the cylinder.

Safety Considerations and Environmental Factors

When using hydraulic cylinders, safety measures are essential to protect operators and equipment. It is important to follow the manufacturer’s instructions for use and maintenance, and to use protective equipment when necessary. It is also necessary to consider environmental factors when using hydraulic cylinders, such as temperature, humidity, and dust. Regular maintenance is essential to ensure the safety of the cylinder and the equipment it is installed on.

Troubleshooting and Common Problems

Here are some common problems and troubleshooting tips:

- Leaking: Check the seals and replace if necessary.

- Poor performance: Check the calibration and adjust if necessary.

- Overheating: Check the lubrication and replace if necessary.

Preventive measures include regular maintenance, inspection, and lubrication, and careful use of the cylinder to minimize wear and tear.

Design Considerations and Selection Criteria

When designing and selecting hydraulic cylinders, it is essential to consider their load-bearing capacity, sealing, durability, safety, and maintainability. Here are some points to consider:

- Load-bearing capacity: The cylinder must be able to withstand the maximum load it will be subjected to during normal operation.

- Sealing: The cylinder must be properly sealed to prevent leaks and contamination.

- Durability: The cylinder must be made of durable materials that can withstand harsh environmental conditions.

- Safety: The cylinder must be designed with safety features to prevent accidents and reduce hazards.

- Maintainability: The cylinder must be easy to maintain and repair to reduce downtime.

It is also important to use various seals like piston seals, rod seals, and cylinder seals, made of wear-resistant materials like polyurethane and nitrile rubber, and to lubricate the cylinder regularly with the appropriate hydraulic oil.

Regular maintenance and preventive measures, such as inspection and lubrication, can extend the service life of the cylinder and ensure its performance and safety.

About Our Company

We are a manufacturer of replacement hydraulic cylinders, with a complete range of products, and have become one of the leading manufacturers and wholesale distributors of hydraulic cylinders in the domestic and international markets.

Professionalism and International Certification

Our company has a team of professional engineers and technicians, and has passed international certifications such as ISO9001:2015, ensuring the quality and reliability of our products.

Customization Service and Production Equipment

We provide customized services to meet the unique needs of our customers, and our production equipment is advanced and efficient, ensuring fast delivery and high quality.

After-sales Service

We have a comprehensive after-sales service system to provide timely and effective technical support and maintenance services to our customers.

Author: lyl.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: