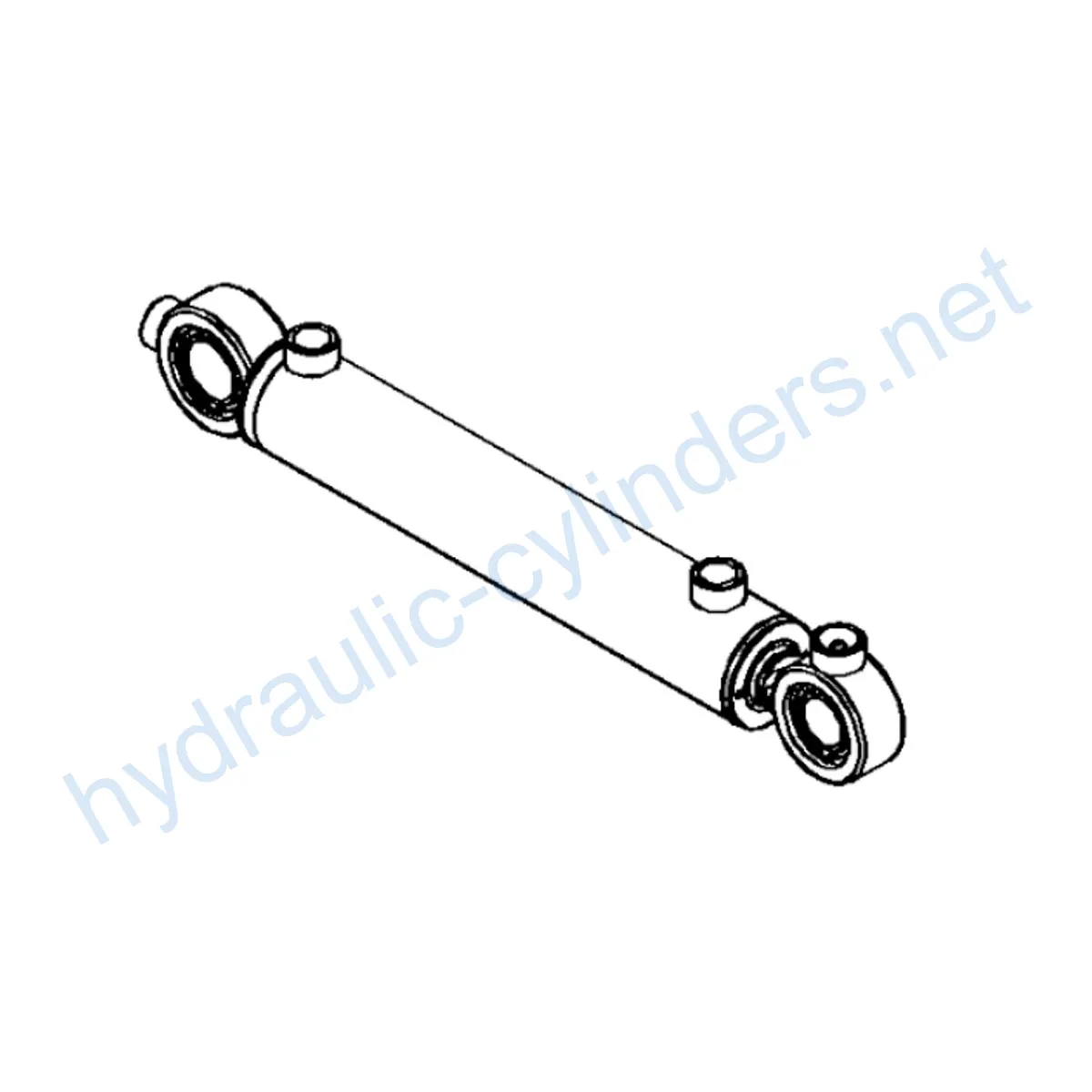

Replacement Of F686625 Hydraulic Cylinder

As one of the hydraulic cylinders manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Mail:sales@hydraulic-cylinders.net

Manufacturer supplier exporter of hydraulic cylinders.

Replacement Of F686625 Hydraulic Cylinder

Product Introduction

The Replacement Of F686625 Hydraulic Cylinder is a vital component used in various machinery. It plays a crucial role in providing hydraulic power to perform different tasks. This cylinder is designed to withstand heavy loads and ensure efficient operation.

Specifications

- Weight: 12.34 lb

- Height: 3.5 in

- Length: 19 in

Model

The model of this hydraulic cylinder is [insert model here].

Features

- Improved Equipment Performance: Replacing damaged or worn-out hydraulic cylinders restores the normal operation capability of the equipment, ensuring its performance in various applications.

- Enhanced Safety: Regularly replacing hydraulic cylinders reduces safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

- Overload Protection: New cylinder designs often incorporate better overload protection mechanisms, thereby increasing safety.

- Quick Installation: Modern hydraulic cylinders are designed with easy installation and replacement in mind, minimizing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it convenient to obtain replacement parts in the market.

Applications

The Replacement Of F686625 Hydraulic Cylinder finds application in various industries. Here are a few examples:

- Excavators: Hydraulic cylinders in excavator arms or buckets can get damaged due to prolonged use or overloading, requiring replacement to restore normal operation.

- Cranes: Hydraulic cylinders in crane boom systems are prone to wear and tear during frequent lifting and lowering processes, necessitating regular replacement for safety purposes.

- Tractors: Hydraulic cylinders in front-end loader attachments of tractors may develop leaks or performance issues due to continuous lifting and tilting operations, demanding replacement.

Maintenance Tasks

Proper maintenance is essential for optimal performance and longevity of the Replacement Of F686625 Hydraulic Cylinder. Here are three common maintenance tasks:

- Regular Inspections: Periodically inspect the cylinder for any signs of damage, leakage, or abnormal wear. This ensures early detection of potential issues.

- Appropriate Lubrication: Adequately lubricate the cylinder using recommended hydraulic oil to reduce friction and enhance smooth operation.

- Seal Replacement and Calibration Checks: Replace worn-out seals and regularly calibrate the cylinder to maintain optimal performance. Proper alignment during installation is crucial for effective functioning.

Safety Considerations and Environmental Factors

When using the Replacement Of F686625 Hydraulic Cylinder, it is vital to follow safety measures to prevent accidents or injuries. Implementing proper safety precautions ensures the well-being of operators and protects the surrounding environment.

Troubleshooting and Common Issues

Here are some common troubleshooting tips and solutions for potential issues that may arise with the Replacement Of F686625 Hydraulic Cylinder:

- Issue 1: Leakage from the cylinder.

- Issue 2: Cylinder not extending or retracting fully.

- Issue 3: Irregular cylinder movement or noise.

Solution: Check and replace damaged seals or gaskets. Ensure proper alignment and tight connections.

Solution: Inspect for any obstructions or debris. Lubricate the cylinder and check for proper hydraulic fluid levels.

Solution: Verify proper alignment and mounting of the cylinder. Inspect for any damaged or worn-out components and replace if necessary.

Preventive Measures

To minimize potential problems, consider the following preventive measures:

- Regularly inspect and maintain the hydraulic system.

- Follow recommended lubrication schedules.

- Ensure proper alignment and installation of the cylinder.

- Provide training to operators on safe usage and maintenance practices.

Product Design Considerations and Selection Criteria

- Bearing Capacity: The Replacement Of F686625 Hydraulic Cylinder is designed to handle heavy loads and provide reliable performance.

- Sealing and Durability: The cylinder incorporates high-quality seals and durable materials to ensure a long lifespan and prevent leakage.

- Safety: The design of the cylinder emphasizes safety features to reduce the risk of accidents and ensure operator well-being.

- Maintainability: The cylinder is designed for ease of maintenance, with accessible components and clear instructions for repair and replacement.

Sealing and Lubrication

The Replacement Of F686625 Hydraulic Cylinder utilizes various sealing elements, such as piston seals and rod seals, made of wear-resistant materials like polyurethane and nitrile rubber. The cylinder body and threaded end surfaces undergo precise treatment to enhance wear resistance. Regular lubrication with the appropriate amount of hydraulic oil is necessary for proper functioning.

Regular Inspections and Preventive Maintenance

To ensure the longevity of the Replacement Of F686625 Hydraulic Cylinder, perform the following maintenance tasks:

- Inspect the cylinder regularly for any signs of damage or wear.

- Follow recommended inspection, repair, and replacement procedures.

- Provide replacement parts and rebuilding services for optimal cylinder performance.

- Offer tips and techniques to extend the lifespan of the hydraulic cylinder.

Installation Guide

Proper installation is crucial for the optimal performance of the Replacement Of F686625 Hydraulic Cylinder. Follow these guidelines:

- Ensure the cylinder is aligned correctly with the equipment.

- Provide precise instructions for aligning and securing the cylinder.

- Recommend the use of appropriate installation brackets to secure the cylinder.

- Advise on inspection, repair, and replacement procedures for efficient operation.

Our Company

We are a leading manufacturer and wholesale distributor of replacement hydraulic cylinders. With a wide range of products, we have established ourselves as a reputable supplier in both domestic and international markets.

Professionalism

We pride ourselves on our professionalism and expertise in the field of hydraulic cylinder manufacturing.

International Certifications

Our products meet international quality standards and certifications, ensuring reliability and performance.

Customization Services

We offer customization services to meet specific customer requirements and provide tailored solutions.

Production Equipment

We utilize state-of-the-art production equipment to ensure precision and efficiency in manufacturing.

After-Sales Service

Our dedicated after-sales service team ensures customer satisfaction by providing support and assistance when needed.

Author: lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: