Relevant Industries: Machinery Mend Outlets, Construction functions

Showroom Location: None

Problem: New

Variety: Vibratory Roller

Vacation Velocity: ~3.5km/h

Grade Ability: thirty%

Energy: 9.7KW

Dimension(L*W*H): 2500*760*1140 mm

Weight: .8 TON

Warranty: 1 Year

Hydraulic Pump Brand name: SAUER-DANFOSS

Hydraulic Valve Manufacturer: SAUER-DANFOSS

Motor Brand name: HONDA

Special Promoting Stage: Limited turning radius

Drum diameter: 355 mm

Drum: Double Drum Roller

Thrilling Drive: 20KN

Machinery Check Report: Presented

Online video outgoing-inspection: Supplied

Marketing Type: Hot Item 2019

Warranty of main parts: 1 12 months

Main Components: Motor, Motor

Engine: HONDA GX390/CHANGCHAI

Engine kind: gasoline/diesel

Generate mode: Variable plunge pump, stepless velocity change, 2 wheel

Steering manner: Hydraulic cylinder steering

Steering method: Swivel support plate

Vibration wheel: Entrance+Rear

Travel type: Mechanical transmission, electromagnetic clutch

Vibration frequency (HZ): 65

H2o spray form: Gravity-type water

Hydraulic oil capacity(L): 28

Packaging Details: iron frame or customised wood bundle for Offering Models:One product Solitary bundle size: 196X89X128 cm Solitary gross excess weight:one thousand. KG Bundle Type:Wood box for 1 ton ST1000 excess weight of mini highway roller compactor value

Port: CHINA PORT

.8 ton NEW hydraulic walk guiding double drum vibratory highway roller 800kg hand held asphalt rollers

ZheJiang Storike Engineering & Mechanism Co., Ltd is specialized in the sales and production of modest highway roller, compact ram, mobile lighting car, hydraulic electricity station, troweling equipment and other construction device. Our items are extensively used in municipal and freeway pavement street roller routine maintenance, tiny region compacting and frustrated trough compacting creating and building resources this sort of as all types of non-cohesive components, sandy soil, gravels, sand-macadam mixtures, stabilized soil, bituminous concrete, and so forth. Specially it is most economical for basis treatment method of country street, 1 Round Bore Stainless Steel Two-Piece Clamping Shaft Collar Double Split Shaft Collar large community street, water conservancy building and genuine estate growth and backfill compaction of other mini-type assignments.

Short IntroductionHighway rollers (at times referred to as a road roller, or merely a highway roller) are compactor-sort development car used to compact soil, gravel, concrete or asphalt in highway and foundation development. Equivalent drums are also utilized in landfills or agriculture.Street rollers use the fat of the vehicle to compress the area becoming rolled (static) or just take advantage of mechanical advantages (vibration). Preliminary compaction of the foundation layer for road projects is done making use of pad toes or “sheep’s ft” roller rollers, which enable for greater compaction densities thanks to the more compact surface spot of the pads.

Technical specs

| Merchandise NO/Details | SVH80 | SVH80C |

| ENGINE | ||

| Engine | HONDA GX390 | CHANGCHAI |

| Motor sort | Single cylinder, OHV, air-cooled, 4-stroke, gasoline | One cylinder, vertical, air-cooled, 4-stroke, diesel |

| Quantity of cylinders | 1 | |

| Output electricity (KW) | nine.seven | six.three |

| Rating velocity(RPM) | 3600 | |

| Gasoline consupmtion(G/KWH) | 313 | 320 |

| Lubricating oil volume(L) | one.1 | 1.sixty five |

| DRIVING | ||

| Electrical equipment(V) | 12 | |

| Generate mode | Variable plunge pump, stepless pace adjust, 2 wheel | |

| Going for walks speed (KM/H) | 0–3.five | |

| Theoretical climbing potential(%) | 30 | |

| STEERING | ||

| Steering method | Hydraulic cylinder steering | |

| Steering system | Swivel assist plate | |

| EXCITING System | ||

| Vibration wheel | Front+Rear | |

| Push form | Mechanical transmission, Manufacturing facility source agricultural sprayer pto tractor boom sprayer electromagnetic clutch | |

| Vibration frequency (HZ) | 65 | |

| Vibration amplitude (MM) | 0.five | |

| Exciting power(KN) | 20 | |

| SPRINKLING Method | ||

| Drinking water spray kind | Gravity-kind water | |

| CAPACITY | ||

| Hydraulic oil capacity(L) | 28 | |

| Fuel potential(L) | 6.5 | three.five |

| Water tank potential (L) | 30 | |

| SIZE | ||

| Operating width(MM) | 760 | |

| All round size(MM) | 2500 | |

| Equipment top(MM) | 1140 | |

| Floor clearance(MM) | 170 | |

| Wheel keep track of(MM) | 650 | |

| Width of wheel(MM) | 700 | |

| Diameter of wheel(MM) | 355 | |

| Drum thickness(MM) | 10 | |

| WEIGHT | ||

| Bodyweight(KG) | 800 | |

| Static load(N/CM) | fifty eight/63 | 56/sixty four |

Product Features1.The device is outfitted with the manufacturer electricity,brand-identify high quality assurance,excellent functionality,effortless to start.

2.The machine is selected of intercontinental brand name-title Hydraulic variable pump and quantitative mator,repeatedly variable,it can stroll backward and forward.

3.It has Hydraulic steering,steering mild and versatile.

4.It has finished manage perform,to completely control the equipment operating at any time.

5.It makes use of the Japanese-made Nsk(seiko)bearings ,to make sure the machine’s efficiency.

six.It is set up of luxurious seats,straightforward adjustment,cozy function.

7.It has streamlined human body layout,a lot more stunning and generous.

8.The machine’s surface area is dealt with by spray.

9. The product has handed CE certification.

Feedback Feedback

Exhibition

Packing Shipping

Solution ApplicationOur goods are used in municipal, freeway pavement maintenance functions,

also utilize to groove, pipe trench backfill compaction in the construction engineering,

constructing construction and square homework, rolling lawns, Trailer axles with electrical brakes in stock farm trailer axles for sale used trailer axle and so forth.

Very hot Sales three hundred KG to 8 Ton Highway Rollers wander guiding highway roller experience on road roller single drum street roller double drum highway roller

330 kg walk driving road roller 550kg walk behind double mini highway roller 800KG walking kind hydraulic road roller 800KG experience on highway roller 1 ton highway roller 1.2 ton hydraulic road roller 2 ton road roller 3 ton road roller 4 ton asphalt rollers 5 ton roller compactor 8 ton highway roller

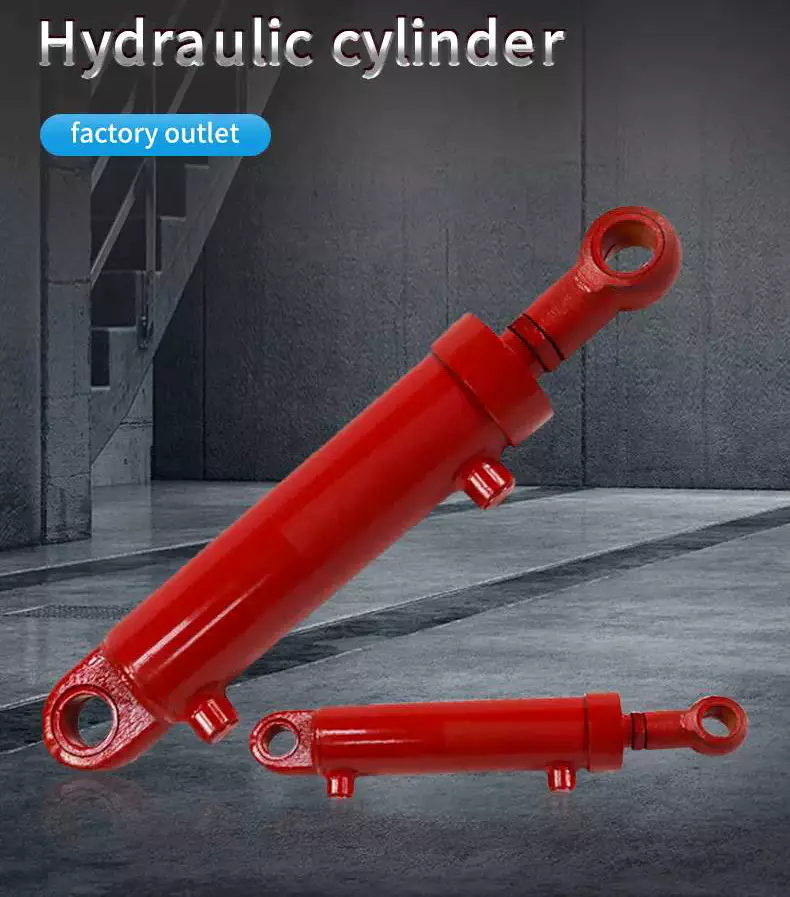

Types of Hydraulic Cylinders

Besides being used for construction and manufacturing machinery, hydraulic cylinders are also used in elevators and vehicles. In fact, the use of hydraulic cylinders has become increasingly common in the recent years.

Single-acting cylinders

Unlike double-acting hydraulic cylinders, single-acting hydraulic cylinders are less complex and are easy to install and maintain. They are also more efficient and compact. They can also be used in applications that require only one direction of motion. They are also useful in applications where space is limited, such as in a small industrial or commercial setup.

Single-acting hydraulic cylinders are usually used for simple lifting and positioning jobs. They also are useful for clamping and diagnostic instrumentation. They are cheap to manufacture and are very easy to install. They are also easy to maintain, which makes them ideal for rugged equipment.

Single-acting hydraulic cylinders are used in a variety of applications, including pumps, internal combustion engines, diagnostic instrumentation, and positioning. They have advantages and disadvantages, but they are an ideal solution for many applications.

Single-acting cylinders typically have one port, and a spring is used to force the piston into its position. The spring then retracts the piston into its previous position. This process can become irregular over time. The spring also requires venting, and can allow foreign particles to enter the cylinder.

A single-acting cylinder can also be retracted by gravity. This is called a spring return cylinder. Some single-acting cylinders have a second piston to forcefully retract the piston into its original position. This can be a problematic operation. The result can be uneven strokes.

Generally, single-acting hydraulic cylinders are not as powerful as double-acting hydraulic cylinders. They require less air, which can boost efficiency. However, their size can be a drawback. They are also susceptible to particles entering the cylinder, which can cause slow performance decline and malfunctions.

Single-acting hydraulic cylinders are ideal for applications with space constraints. They are also useful for compact operations and light assembly. They also save on piping costs. They are suitable for industrial applications such as tow trucks and bulldozers. They are also used in commercial and light industrial applications.

Single-acting hydraulic cylinders are simple to use, but may not provide the same power as double-acting cylinders. They may be less durable, and can also be subject to wear and tear, particularly in the area of retraction.

Welded body cylinders

Compared to other types of cylinders, welded body hydraulic cylinders are more compact in size and less prone to wear and tear. This type of cylinder is commonly used in construction and heavy equipment applications. These cylinders are designed for rugged environments. They are typically used in oil rigs, large off-road vehicles, and cranes.

They have less sharp corners and are easier to customize than other types of cylinders. They are also less expensive to manufacture. In addition, they can be manufactured in a variety of different materials. They are available in different lengths and thicknesses. They are also able to be fabricated using CNC turret punching and MIG welding methods. They are also available in different configurations.

They also have heavy-duty piston seals that provide consistent performance in heavy-load applications. They are also able to be used in applications with large temperature swings. They are also resistant to corrosion.

Welded body hydraulic cylinders are commonly used in mobile machinery applications. This makes them highly versatile and able to fit into tight spaces. They are also used in material handling and lift truck applications. These hydraulic cylinders are also more durable than tie rod type cylinders, which means they are less likely to fail.

They are also available in a variety of different metals. They are also available in rolled or pressed formed shapes. They can be used in press braking, shearing, and rolling structural steel. They are also available in oil and gas applications. They are also available in a variety of sizes from 3 to 169 inches in diameter.

These cylinders are designed to be durable and versatile. They are also designed to accommodate multi-stage adjustable cylinders. They are also able to accommodate custom provisions and are designed to fit into tighter machinery designs. They are also able to be manufactured in a variety of different materials, including high-strength low-alloy steel, 300 and 400 grade stainless steel, and Hastelloy(r) alloys.

They also have a smooth exterior surface. This means there are fewer sharp corners and places where moisture and dirt can settle. The cylinders also have a high level of precision tolerance, ensuring that they can handle high pressures without the metal flexing or sagging.

Tandem cylinders

Often used in heavy industrial applications, tandem hydraulic cylinders are an important part of maintaining the functionality of heavy industrial machinery. Unlike a single cylinder, a tandem cylinder produces twice as much force. They are widely used in barges, cranes, elevated work platforms, fork lift trucks, and a number of other industrial applications.

Hydraulic cylinders are a form of power transfer system that operates on the same principle as pneumatic systems. This allows for infinitely variable force. They are also designed with locking safety mechanisms to prevent accidental damage. They are available in various materials for different applications.

Hydraulic cylinders work by using a piston rod that is thrust through an open gland at one end of the cylinder. This piston rod is then retracted when pressurised fluid bursts out of the cylinder. Its position is controlled by a seal and steel ring. These materials have been used in a variety of industries such as forestry, construction technology, and aircraft development.

Tandem hydraulic cylinders are also used in agricultural equipment such as crop sprayers. They are also used in heavy industrial machinery such as mining equipment.

These cylinders are manufactured by a number of companies including Eaton Corporation, Bosch Rexroth AG, and Caterpillar Inc. In addition, they can be customized to fit your specifications. They are also available in custom air cylinders with a minimum base material of 50,000 psi and a yield of 100,000.

There are a number of types of tandem cylinders. They can be differentiated into non-differential, double rod, balanced, cushioned, and spring return.

Cylinders in tandem typically have two chambers that are the same size. The first chamber is connected to the second cylinder by a port. The second chamber is operated by oil that is ejected from the first cylinder. This ensures that the next steering movements do not occur before the primary piston has completed its stroke.

Tandem hydraulic cylinders are easy to install and are designed to be extremely versatile. They are also extremely reliable. Pacoma is a leading provider of double acting cylinders that stand up to intense pressures. Its cylinders are designed with a solid construction and high-quality components.

Cushioned cylinders

Typically, cushioned hydraulic cylinders are used in manufacturing equipment. They are used to reduce shock waves in the hydraulic circuit, to improve productivity and to reduce maintenance costs. They are also widely used in automobiles.

These cylinders feature a limiting device on the piston head. This device reduces excess load at the end of the outward stroke, which decreases the piston’s speed and vibration. This reduces the total working cycle time and increases productivity.

Cushioned hydraulic cylinders are made using a variety of techniques. Some are used to reduce shock waves and others are used to limit impact forces. However, these techniques do not allow for precise control over the amount of cushioning. This can lead to improper adjustment and reduced performance.

These techniques may require regular maintenance. Cushioning readjustment is often required when changing operating conditions. This can have a significant impact on a machine’s performance. For this reason, it is important to have regular preventive maintenance.

The cushioning of a cylinder is controlled through a series of valves. Each valve is located at a different point on the cylinder. This allows for an optimal cylinder adjustment that reduces oscillations and improves total working cycle time. It can also help to save energy and maintain a quiet working environment.

There are two basic types of cushioned hydraulic cylinders. The first is a spear-type design. This type of cushioning includes a sleeve or spear that enters and exits a concentric pocket. These cylinders require space in the end cap.

Another type of cushioned hydraulic cylinder is a welded cylinder. This cylinder has a piston rod ring that forms an annular restriction when the piston rod is axially moved into engagement with land. The area of the annular restriction increases as the piston moves closer to the head of the cylinder. When the piston moves in the opposite direction, the ring bypasses the annular restriction and the hydraulic fluid enters the cylinder.

When designing a hydraulic cylinder, it is important to consider the amount of cylinder pressure. This is a critical factor for selecting seals and tube wall thickness.

editor by czh 2023-02-24