Custom-made assistance: OEM, ODM, OBM

Product name: Double welded telescopic hydraulic cylinder

Color: blue, green, yellow,red, black,orange

Working Force: 21 MPA

Entire body Content: Metal

Rod Materials: Metal/Iron

Bore Diameter: 50MM

Seals: Parker,Merkel,Hallite

Variety: Hydraulic Cylinder for sale

Identify: Entire world greatest dump truck lift desk log splitter hydraulic cylinder

Packaging Information: (1) Foam wrap packing, then in picket circumstance. (2) 20/GP or 40/GP container.

Port: HangZhou, ZheJiang or ZheJiang

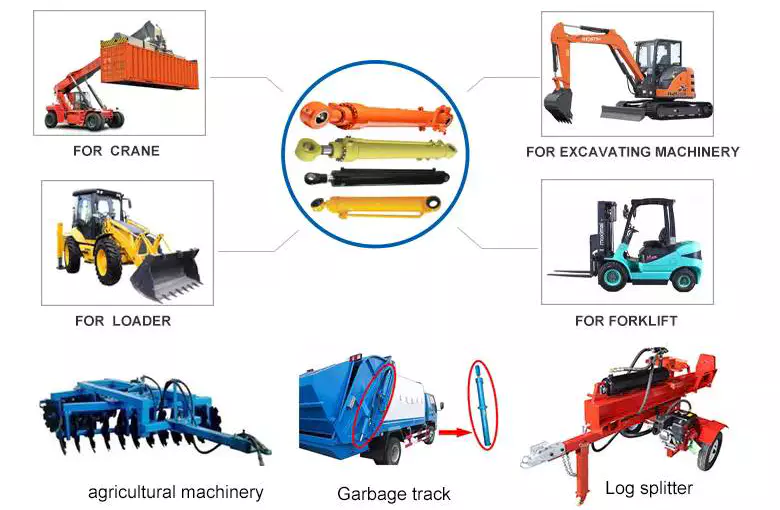

Hydraulic pump telescopic cylinderTopa is a one particular-stop telescopic hydraulic cylinder producer with substantial encounter in custom made developed hydraulic cylinder for boom truck. CZPT can design and style and bosch CZPT hydraulic cylinder no subject how sophisticated. We provide entire services package deal in customization from style to supply with European technologies and American specifications.Our common cylinder inculde Tie rod hydraulic cylinder HTR, weld cylinder HCW HMW and Snow Plow Cylinder, Telescopic Cylinder,Hydraulic tipping cylinder,Log Splitter Hydraulic Cylinder,Loader hydraulic cylinder,Hydraulic Bucket Tilt Cylinder. We also could customized. Merchandise show The size of a hydraulic cylinder is the whole of the stroke, the thickness of the piston, the thickness of base and head and the length of the connections. Typically this size does not match in the device. In that case the piston rod is also used as a piston barrel and a next piston rod is utilized. These types of cylinders are named telescopic cylinders. If we phone a standard rod cylinder single phase, Weighty responsibility complete enhance needle bearing NAV RNAV sequence NAV 4009 for lower sound and substantial velocity electric powered motors,automotive telescopic cylinders are multi-stage units of two, three, 4, five, or more stages. In standard telescopic cylinders are a lot far more expensive than typical cylinders. Most telescopic cylinders are one performing (thrust). Double performing telescopic cylinders need to be specifically made and manufactured. 1.Every stage electroplate difficult chrome2.lighter and less difficult to maintenance3.Higher high quality alloy seamless steel pipe have far better mechanical properties4.The entire world popular brands of seals, this kind of as HALLITE, PARKER,etc5.Entire world-class processing engineering makes certain secure and dependable high quality. Software Temperature resistive, Good corrosion ,Resistive electrical power and Hydraulics cylinders to work in harsh circumstances. For compact retracted proportions and lengthier journey, this kind of as trailer lifting, tipper and trailer substance managing, mining, development, oilfield, developed to endure severe apps and operate environments. 1-way, EK EF Ball Screw Support Device FK8 finish support for SFU Ball Screw Stop Holder CNC Elements 2-way and 3-way dump vans for agricultural and light-weight/medium industrial apps Our Benefits We could make Telescopic standard hydraulic cylinder, from bore 2. inch to 5. inch, which telescopic cylinder hydraulic varieties you need to have, remember to speak to us. Test Process Topa Cylinder has handed ISO TUV certification, High quality is not only constrained to our products, it need to also be existing in every of the services provided and in the processes of our administration. Each and every cylinder one hundred% check just before shipping and delivery. Cylinder examination methodAll the cylinder approach examination is strict, we check out every single parts size and quality, Good quality elements are constructed to endure pressureand restrict fluid contamination. Pressure testReturn Line Screening Mid-Stroke TestingHydrostatic TestingThese take a look at make confident you obtain quality hydraulic cylinder, enhance the lifestyle of your cylinders Finally examinationReturn Line Screening Mid-Stroke TestingHydrostatic TestingThese test make certain you obtain good quality hydraulic cylinder, boost the lifestyle of your cylinders Brightness examinationGet a long stroke from a compact deal that matches virtually wherever by deciding on a telescopic hydraulic cylinder. Interlocking sections contract and expand as needed to generate up to 2500 CZPT where ever the drive is necessary. Galvanizing thickness testTelescopic hydraulic cylinders utilize multiple nested levels, obtaining a long working stroke in compact/retracted type. Intense Hydraulics designs and engineers application-particular telescopic cylinders, goal-built to stand up to demanding programs and function environments. Hardness examinationAn skilled engineering group aids you work by way of style considerations to make certain your cylinder satisfies your requirements. Workshop Our hydraulic push cylinder will maximize the effectiveness of your mobile hydraulic methods, trying to keep your tools running more time,decreasing down time, and preserving you funds. Chopping CNC maching CNC maching Weld Assembly Paint Packing&Shipping We deal well for each and every hydraulic cylinder, make confident you get best cylinder hydraulic. One particular box for 1 cylinderA single cylinder packing in 1 box Palletfifty-two hundred cylinders packing in 1 pallet.The pallent is plywoods with metal belt. Shield cylinder Container17-twenty pallets into 1 20GP Container Associated products Topa can design and deliver hydraulic cylinders no make a difference how sophisticated they are. We give a entire services bundle incustomization. from style to supply with European technology and American specifications. Remember to notify us which 1 you require, 1 sample could make for you. Welded Swivel Eye Hydraulic Cylinder HMW weld hydraulic cylinder Hydraulic Tipping Cylinder Snow Plow Cylinder Hydraulic Tie Rod Cylinder Snow Plow Hydraulic Cylinder Make contact with US We could make all kinds of hydraulic cylinder, standard and personalized hydraulic cylinder. Make sure you explain to us which 1 you need to have, we could make sample for you. Make sure you contact us.

Different Types of Hydraulic Cylinders

Whether you have used hydraulic cylinders before or have never heard of them before, you should know that they are a type of mechanical actuator that is used in a variety of different applications. They can be found in many different types of machinery, from elevators to construction equipment.

Piston seals

Choosing the right seal is essential for the proper performance of hydraulic cylinder applications. A seal that is used in the wrong manner can result in reduced productivity and damage to machines. If you’re not sure which seal is right for your application, it’s best to choose a seal that’s designed for your application.

Piston seals are a type of seal that is designed to keep hydraulic fluid from flowing past the piston. These seals are made from different materials and are used in a wide variety of applications.

A piston seal can be single-acting or double-acting. A single-acting seal is designed to move the piston in a single direction, while a double-acting seal is designed to seal pressure from both sides of the piston.

Piston seals can be made from different materials, such as polytetrafluoroethylene and rubber. These materials provide low friction and superior durability under extreme conditions. They are often used in hydraulic presses and mobile hydraulics.

Polytetrafluoroethylene is a popular choice for piston seals because it has a low coefficient of friction. It can handle higher temperatures than other materials and is highly recommended.

Polytetrafluoroethylene piston seals are usually used in mobile hydraulics and hydraulic presses. They feature a round nitrile loader that faces the piston. This ring is filled with 15% glass-filled PTFE, providing low friction and real-time availability.

A piston seal’s material can determine the strength of the seal and its durability. Rubber seals are used in situations that require high compressibility and flexibility. PTFE piston seals are also recommended because of their low coefficient of friction.

Another type of seal is a dynamic seal. These seals contain pressurized fluids and can move in a rotary or oscillating motion. The seal is supported by guide rings that prevent metallic contact between the axial and rotational components.

Seals for hydraulic cylinders are used in a variety of applications. They are made from different materials, including rubber, plastic, and PTFE. They are available in a variety of shapes and sizes, depending on the application.

Seals for hydraulic cylinders must be used in the correct tolerances and surface finishes. The material of the seal must provide the appropriate amount of flexibility and strength. The material must also provide the ability to allow a thin lubrication film to pass through the seal’s contact area.

Coatings

Using the right coatings for hydraulic cylinders reduces the risk of abrasion, pitting, wear, and corrosion. The coatings also have the advantage of providing chemical shielding and wetting properties.

A hard chrome coating has been traditionally used on hydraulic cylinder rods. Traditionally, the coating is deposited using electroplating processes. The hard chrome surface provides reasonable corrosion resistance. However, the coating may interfere with lubrication of the rod. This decreases Rmax and Rz, and may increase the seal failure rate.

Another alternative is a tungsten carbide coating. The tungsten carbide coating has better corrosion resistance than traditional hard chrome. It can be used as a replacement for hard chrome coatings. It is also used on loader cylinders on compact tractors.

A variety of other coatings are available for hydraulic cylinders. These include ceramic, plastic, and metal-oxide ceramic coatings. These coatings can be applied externally or internally.

Another option is thermal spray. Thermal spray is an industrial process that uses engineered materials to deposit metallic or ceramic materials onto surfaces. This reduces friction and increases heat shielding. The coating also increases wear life. Thermal spray can be used to repair damaged surfaces and prevent future breakdowns.

An additional surface treatment is liquid nitrating. Liquid nitrating produces a hard iron nitride layer that is useful for surface enhancement. The process involves spraying 50 grams of powder onto a substrate material. The powder is then fed into a powder feeder. This is repeated until the desired thickness is reached.

The primary function of coatings is to protect the cylinder from chemical and physical attacks. In addition to corrosion and wear resistance, black color coatings also provide electrical insulation and wetting properties.

Hydraulic cylinders can be coated internally or externally. External coatings are particularly useful for areas subjected to critical working conditions. Hydraulic cylinders used in underwater applications, such as subsea hydraulic systems, are subject to saline water that can cause pitting corrosion. In addition, external abrasive agents can act harshly on the rod.

The primary function of coatings for hydraulic cylinders is to protect the cylinder from chemical attacks. The most important mechanical properties are hardness, yield strength, and tensile strength.

Non-differential cylinders

Unlike a differential hydraulic cylinder, a non-differential cylinder has no internal valves to control the flow of hydraulic fluid. Instead, it has two ports – one at each end of the cylinder – that allow equal fluid flow to both sides. In addition, a piston rod will extend at both ends of the cylinder. This makes the non-differential cylinder a good choice for applications where a task can be accomplished at each end.

It also has a clevis that allows the user to make precise changes to pressures. A steel ring, piston and seal also contribute to the stability and control of the cylinder.

A non-differential hydraulic cylinder is not only easy to install and maintain, but they are also inexpensive. They can be used in a variety of applications, including agriculture, manufacturing, mining, and construction technology. They are commonly made of aluminum alloys or plastics, with stainless steel end caps. These cylinders are typically designed for light duty cycles. They are also economical when they are not needed for long service life.

The cylinder industry has two main designs: single-acting and double-acting. The single acting cylinder has a single piston rod, while the double-acting cylinder has two piston rods. The two-acting cylinder has a larger bore, which allows for greater force transfer.

The cylinder industry also uses an alternative manufacturing process that locks three pieces together. This is referred to as the spring-return model. Most non-repairable cylinders have stainless steel end caps.

An alternative to the spring-return model is a welded rod cylinder. They are compact and suitable for mobile applications. However, they are not easy to disassemble. The rod extension makes the cylinder unusual.

The most important benefit of the cylinder is its ability to convert incompressible hydraulic fluid energy into work. This is done by applying a hydraulic pressure force over the annular area of the piston during retraction. The cylinder also uses an internal spring to control the flow of fluid. This combination of materials and technologies makes a non-differential cylinder a great choice for applications that require a compact design without sacrificing efficiency.

Welded rod cylinders

Depending on the size and pressures of the application, welded rod hydraulic cylinders can be used for various applications. They are often used in material handling equipment, cranes, oil rigs, and other mobile hydraulic equipment. These cylinders are designed to handle moderate to heavy loads and are durable.

There are two main types of welded rod hydraulic cylinders. They include single-acting and double-acting models. Double-acting models are ideal for precision operations and high-pressure applications. They are manufactured with additional features for increased durability.

The standard hydraulic cylinder is composed of a cylinder barrel, a piston rod, and a seal. These three elements provide stability, control, and protection from leaks. The piston rod is made from medium carbon steel S45C, which is polished to mirror class.

To ensure that the hydraulic cylinder performs efficiently, it needs to have a smooth surface. This is achieved through honing. In addition, the inside of the cylinder tube must be durable. It is also important to maintain a clean working environment.

Welded rod hydraulic cylinders have more complex designs than tie rod cylinders. These cylinders use high-strength threaded steel rods to hold end caps together. Threaded bolts extend from bottom caps to top caps. This design makes it easy to disassemble and service the cylinder.

The most common applications for welded rod hydraulic cylinders are mobile equipment. These cylinders are used in construction, metal fabricating, OEM trailer manufacturing, and agricultural applications.

Tie rod hydraulic cylinders are also popular. They work well in low-pressure applications. They can be disassembled easily using standard tools. They are also less expensive to manufacture. However, they are less durable than welded cylinders.

Welded rod hydraulic cyclinders are durable, compact, and ideal for industrial and commercial applications. They are also lightweight, making them perfect for heavy-duty applications. They have a low profile design, which helps them to fit in tight spaces. They can also be custom-engineered to meet specific technical requirements.

The main advantages of welded rod hydraulic cylinders are their rugged design, durability, and versatility. They are suitable for a variety of mobile hydraulic equipment, and are ideal for applications that require precise parameters.

editor by czh 2023-06-27