Problem: New

Warranty: 1 Year

Relevant Industries: Restaurant, House Use, Other, Farms, Developing Substance Shops, Printing Retailers, Garment Shops, Producing Plant, Foodstuff & Beverage Manufacturing unit, Construction works , Retail, Power & Mining

Bodyweight (KG): 1

Video clip outgoing-inspection: Supplied

Machinery Check Report: Presented

Marketing and advertising Type: New Merchandise 2571

Warranty of main components: 1 Year

Core Factors: Pump, Bearing

Standard or Nonstandard: Normal

Structure: Sequence Cylinder

Power: Pneumatic

Entire body Material: Aluminum

Brand: DDE pneumatic

Sort: Mini cylinder

Manner of execution: Other

FAQ

| Cylinder fault self check | ||||

| Fault Presentation Fault examination Fault classification Fault rectification How can I Stay away from it | ||||

| Cylinder output weak spot | There is air leakage inside the cylinder and air leakage at the piston seal | Seal failure | Replace the cylinder piston seal assembly | Air pipe and joint ought to be blown cleanse, compressed air ought to be filtered following use |

| Air supply stress is inadequate | Use mistake | Enhance air stress and shorten piping | There will be pressure decline right after the air pressure passes through the long pipe. The cylinder making use of side must be outfitted with triplets to get the strain price of the using aspect, and the air supply can be even more cleaned. If the duration of the pipe can not be shorter, and the force can not satisfy the situation, CZPT manufacturer steering areas left facet travel shaft assy for CZPT Corolla AE101 C-TO001A-8H 610MM2623 you can use the pressurization valve to make up for the stress decline | |

| A leak in the cylinder joint | Seal failure | Wrap the joint about the uncooked substance belt ahead of use | Ahead of making use of the cylinder, check the sealing elements to ensure that there is no evident leakage in the entire pneumatic technique | |

| Cylinder piston resistance turns into huge, soon after running for a period of time of time cylinder cylinder heating | Piston underlubrication | Use error | The oiler lubricates the oil | The cylinder comes with grease in the manufacturing facility and can be utilised with out oil, but as soon as the oil is utilized, it can not be stopped, the oil mist will clean away the grease, and the cylinder is in a point out of no lubrication right after halting the oil offer. Similarly, the presence of moisture in compressed air will also wash away grease, which should be lubricated with an oil mist |

| After a time period of time, the operating resistance of the cylinder is large and the output of the cylinder is weak | The cylinder is ruined by the lateral load. After disassembling, it can be discovered that the cylinder is worn by 1 or the two sides of wire drawing | Use mistake mechanical harm seal failure | Substitute cylinder and piston seal assembly | Cylinders that are not able of lateral loading shall prohibit all types of lateral loading. If the design and style can’t be averted, the load ought to be outfitted with a information rail to steer clear of immediate lateral load on the cylinder |

| The cylinder and the load are not in a straight line. Soon after the cylinder runs for a period of time, the cylinder resistance boosts and the output power decreases | Cylinder eccentricity, ensuing in eccentric use of piston and cylinder. After disassembly, it can be found that the cylinder seems a single-sided or cool aspect wire drawing use | Use error mechanical damage seal failure | Replace the cylinder and piston seal areas | Cylinder to keep away from eccentric use of the piston rod, this kind of as can not make certain that the load and the piston rod in a straight line, 17HS08-1004S 12V 42x42x20mm Bipolar 17HS4571 Stepper Motor NEMA 17 Slim Stepping motor For 3D Printer you can use the floating joint for adjustment. It must be famous that in some tail wagging or piston swinging joints, the cylinder place is not mounted, specially essential |

| The cylinder can not all prolong, managing resistance is huge | Cylinder The cylinder is ruined by effect, and the piston cannot go via the hurt spot | Mechanical injury | Change the cylinder and piston seal assembly if required | The cylinder need to be averted in the procedure of storage and transportation, and the possible affect need to be averted when the products is created and utilised. If the cylinder has been ruined, do not pressure the use of operation, otherwise it will lead to secondary damage to the piston and seal |

| The cylinder is stretched out and retracted generally | The sealing failure of the rear end include and cylinder | Seal failure | Replace the conclude protect sealing part | Do not disassemble the stop go over and cylinder without having authorization |

| Cylinder retracted and unable to extend standard | The seal in between entrance finish go over and cylinder unsuccessful | Seal failure | Change seal assembly | Do not disassemble the finish go over and cylinder with no authorization |

| Dust seal failure at entrance finish protect outlet rod | Seal failure | Replace seal assembly | Do not use the cylinder in negative environment, welding slag, chip waste debris and other impurities will reduce the dustproof seal ring with the motion of the piston rod, resulting in seal harm and failure | |

| Cylinder air buffer failure | Adjustable cylinder, piston buffer sleeve simply because of stroke adjustment, can not attain the gas buffer region is stopped, no buffer | Use error | The fault | Modify the stroke, if not, do not use air buffer. If there is a require for buffering, Factory cost Japan CZPT bearing NA4906 needle roller bearing exterior hydraulic buffering or other external buffering gadgets can be put in |

| The needle valve seal of air buffer is defective and the needle valve is leaking air | Seal failure | Substitute the sealing assembly of the needle valve | Air supply must be employed right after treatment, moist, greasy compressed air, will shorten the support life of rubber seal | |

| The seal ring of the cylinder air buffer is broken | Seal failure | Replace the air buffer seal ring | The air resource ought to be used after treatment method. Soaked and greasy compressed air will shorten the provider lifestyle of the rubber seal. The compressed air must have no impurities, in any other case the seal ring will be abnormal dress in and tear | |

| Detailed evaluation of the circumstance, buyers can assess by on their own, or cooperate with customer support actively deal with. Pneumatic method is a best system, the entrance failure may possibly affect the use of back-stop parts, we hope that when consumers experience irregular issues, they can be rational, tranquil examination, optimistic response, damaging therapy or even psychological treatment are not the correct way to fix the problem. We will make every single work to supply high quality support for every single buyer. | ||||

| The cylinder is out of synchronizationBecause of the variation among personal cylinders and distinct loadsThe exact same variety of cylinder bore pushes the identical load simply because the pressure is appliedDifferent positions guide to diverse cylinder hundreds, or evenDifferent cylinder diameters will lead to cylinder movementThe minimal pressure is various. Compressed air is suppliedThe enhance of air force is a dynamic processStroke, the cylinder that 1st reaches the starting up pressure will begin firstWhen the air cylinder functions, the inflation volume increases, Electrical tricycle four-wheeled modified vehicle assembly 60v 1200w complete drum brake rear differential axle and the impactIf the sound pressure continues to increase, it will causeInconsistent action, even 1 of the cylindersThe next cylinder will not carry on to work until it reaches the endSituation of Design plan of cylinder synchronous actionUse the velocity regulating connector to modify stage by stage to attain simple synchronization. It is not applicable toDemanding events. The pneumatic hydraulic cylinder is utilised to achieve large synchronization precision with the hydraulic incompressible attributes Use exterior mechanical link to recognize steady and reliable synchronous action | ||||

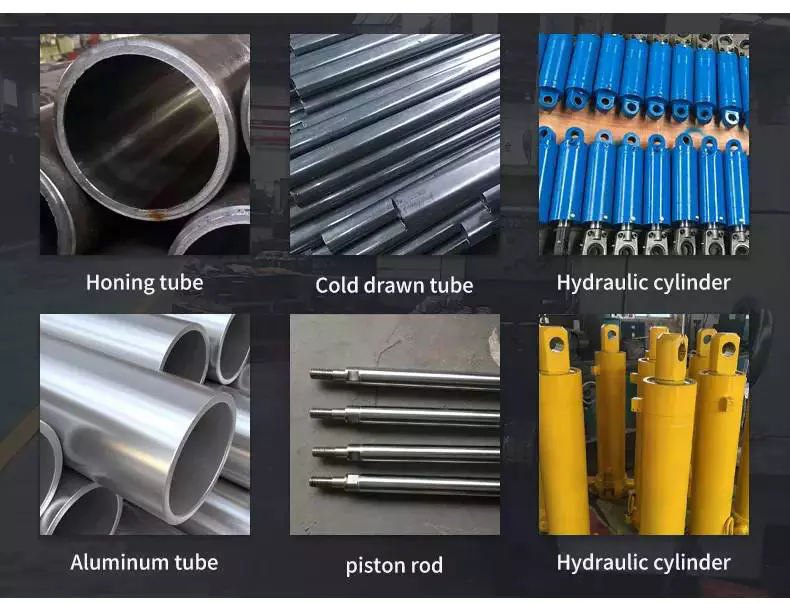

Hydraulic Cylinders and Their Components

Typically, a hydraulic cylinder is used in manufacturing machinery, construction equipment, civil engineering, and elevators. A hydraulic cylinder is also known as a mechanical actuator. A hydraulic cylinder is a type of mechanical actuator that is used to provide unidirectional force.

Piston rod

Choosing the correct rod for hydraulic cylinders can improve the performance and dependability of the machine. While the diameter is always important, the length is also crucial. If the length of the rod is too short, it will crush or fail. On the other hand, if the rod is too long, it will become twisted or misaligned.

The rod seal is the most important seal in a hydraulic cylinder. It protects the cylinder from fluid leaks and system pollutants. It also handles gradual changes in system pressure.

There are many types of seals for hydraulic cylinders. Some of them are special and designed to work under intense pressure. These seals also have backup rings.

A piston rod can be either hollow or solid. It is usually made of steel or stainless steel. It is often coated with hard chrome plating. A polished surface is also an option.

Choosing the correct seal is a crucial step in ensuring the longevity of your piston rod. Rod seals are subject to the most harsh conditions. They need to be made from materials that are slow to wear and will not contaminate the cylinder.

The correct rod seal is also important in preventing fluid leaks. They also protect the cylinder from pressure extremes in the system. If the seal fails, the cylinder will be damaged. The seal is also important because it prevents system pollutants from damaging the rod.

A hydraulic cylinder can be single acting or double acting. Single acting cylinders have one pressurized chamber while double acting cylinders have two. Typically, double acting cylinders have a piston that is extended under hydraulic pressure and retracts under hydraulic pressure.

Piston seals

Choosing the correct hydraulic cylinder piston seal is important to the operation of a hydraulic cylinder. There are various types of seals that can be used to help ensure proper operation of a cylinder. They range from single-action to double-acting seals. The seal’s material and its profile affect its performance.

The materials used to make piston seals range from rubber to thermoplastic polyurethane. The material’s elasticity and strength are also important. Typically, plastic seals have more focus on adding strength to the cylinder than on flexibility.

Rubber seals are used when a higher degree of flexibility is required. They are also used when a higher degree of compressibility is required. Some rubber seals are designed to withstand higher temperatures.

Piston seals are made from a variety of materials, including Viton, nitrile rubber, and polytetrafluoroethylene (PTFE). PTFE piston seals have less friction, which is a good thing. A PTFE seal is also able to handle higher temperatures.

In order to properly seal a cylinder, the seal must maintain contact with the cylinder bore. This ensures that fluid does not flow past the piston. The seal’s profile must also leave a small amount of oil film when it passes along the cylinder bore.

Thermoplastic elastomers are designed to offer superior elasticity. They also stand up to abrasion and high use. They also exhibit unmatched performance at extreme temperatures.

A piston seal can be designed to meet various requirements, including the highest pressures that can be expected. Some manufacturers offer custom sealing solutions. These solutions include testing, according to the customer’s specifications. They can also include failure analysis and system investigations.

Thermoplastic elastomers are also designed to be resistant to tearing. In addition, they are able to maintain a constant pressure for a longer period of time than other materials.

Mounting attachments

Using mounting attachments for hydraulic cylinders can reduce wear and tear on seals and bearings, and provide stability to the cylinder. There are three main groups of mounts: flange, lug, and clevis. Each style is designed for a different purpose. Choose the mount that is best for your hydraulic cylinder.

Flange mounts are a good choice for straight-line force-transfer applications. These mounts come in rectangular or square shapes and can be attached to the head or cap of a cylinder. They are very strong and are not prone to misalignment. They are also available in rod-end styles, which are recommended for tension applications.

Side lug mounts are used for small or light-duty hydraulic cylinders that require a straight-line force transfer. These mounts have lugs on the sides of the mount that are threaded to tie rods. These mounts are primarily used in confined spaces. The lugs can also be pinned on both sides of the mount to prevent movement of the cylinder. The lugs are also strong and can be used in high-pressure environments.

Clevis mounts are also used for arcing loads. They are primarily used on shorter stroke hydraulic cylinders. They can be mounted vertically or horizontally. They are usually used with a knuckle at the rod end of a cylinder. These mounts provide a single pivot point for mounting the cylinder.

Cylinder rod end attachments should be made from spherical bearings to minimize stress on the gland and piston rod. Ideally, they should be positioned as close as possible to the shoulder faces of the trunnion. They should also be threaded to tie rods for a secure connection.

The best mounting style for a hydraulic cylinder is an intermediate fixed-trunnion mount. This type of mount is a good choice for short stroke applications.

Common hydraulic cylinder components

Whether you are looking for a new hydraulic cylinder, or you are considering upgrading the hydraulic cylinders in your current machine, you need to understand the different components of a hydraulic cylinder. Cylinders are used in a variety of applications, including construction, mining, aircraft development, metal sheet shearing, and material handling.

A hydraulic cylinder is composed of two main components. These are the piston and the piston rod. The piston rod protrudes from the cylinder barrel and is attached to the piston inside the cylinder.

A hydraulic cylinder also has seals. These are used to prevent contaminants from entering the cylinder. They are made of many different materials, depending on the application. If the hydraulic cylinder will be operating at a high temperature, it may need a seal made of Viton. In contrast, a hydraulic cylinder operating at freezing temperatures may need a polyurethane seal.

Hydraulic cylinders are also designed to withstand a large amount of force, which means that they need to be able to withstand the pressure of the system. The pressure in the system must never exceed the rated design pressure of the cylinder.

Another important component of a hydraulic cylinder is the cylinder head. It is fitted with a rod gland seal, which encloses the pressure from the other end of the cylinder barrel. A hydraulic cylinder’s head can also be fitted with a check valve, which closes when the stem is clear.

A hydraulic cylinder’s head is also fitted with a rod bearing, which supports the weight of the piston rod. The rod bearing guides the piston rod through the rod gland, and prevents hydraulic oil leakage.

A hydraulic cylinder’s rod can be made from stainless steel or carbon steel. The rod is usually coated with hard chrome plating. The rod can also be made from corrosion-resistant materials, including Inconel.

Common causes of hydraulic cylinder drift

Having a hydraulic cylinder that drifts is not only dangerous, but it can lead to a lot of repair work and costly replacements. Luckily, you can diagnose and fix this problem by performing a few simple tests.

The first step is to ensure that the cylinder is in good working order. It should be checked for general wear, corrosion, and speed. Also, it should be checked for leaks. If there are any leaks, you should fix them right away.

Another way to determine if a cylinder is drifting is to use a pressure gauge. The gauge should be used under controlled conditions to determine if the cylinder is drifting. If the cylinder moves, the problem is likely a leak. You should also check the rod seal.

When the rod seal leaks, it allows fluid to leak outside of the cylinder system. If it does not leak, it should stick to the rod when the rod stops moving. This will prevent a cylinder from drifting and maintain pressure.

The most common cause of hydraulic cylinder drift is a leak. A leak can occur in a number of ways, including through the piston seal or a leak in the holding or pressure release valves. If the leak is in the piston seal, it can lead to a hydraulic cylinder that drifts.

Another common cause of hydraulic cylinder drift is fluid contamination. When foreign particles combine with the fluid, the density can change and oil can seep past seals.

Hydraulic cylinders can experience other issues as well. If the cylinder has an oversized piston diameter, it can cause cylinder drift. A load control valve can also be a problem.

editor by czh 2023-03-19