Software: Fluid Pipe, Boiler Pipe, Drill Pipe, Hydraulic Pipe, Gas Pipe, OIL PIPE, Chemical Fertilizer Pipe, Composition Pipe, Other

Alloy Or Not: Is Alloy

Part Condition: Spherical

Special Pipe: API Pipe, Other, EMT Pipe, Thick Wall Pipe

Outer Diameter: 8 – 630 mm

Thickness: .3 mm— 18 mm

Standard: GB, ASTM A106-2006

Size: 12M, 6m, 6.4M

Certificate: API, ce, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, JIS, GS, ISO9001

Grade: carbon metal, Q195/Q215/Q235/Q345/10#/twenty#

Area Treatment method: Very hot Rolled

Tolerance: ±1%

Processing Provider: Welding, Punching, Cutting, Bending, Decoiling

Oiled or Non-oiled: Slightly Oiled

Invoicing: by theoretical weight

Shipping Time: inside 7 days

Type: Scorching Rolled Hollow Carbon Pipe

Materials: ten#.twenty#.45#15Mn.20Mn.45Mn.30Mn2

Technique: Hot Rolled Cold Drawn

Area: Black Varnish

Use: Oil Gasoline Sewage Transport

Technologies: Seamless Sizzling Rolled

Shape: Round Pipe Tube

Metal Grade: Quality B/X42/X52/X60/X70 L245/L290/S320/L360/L390/L415

Packaging Particulars: Wood pallet or according to customer’s ask for

Port: HangZhou,ZheJiang ,ZheJiang

Advantage:Competitive value, Fast delivery,Huge stock,OEM&ODM,24 hrs true individuals online service Solution Parameter

| Product Identify | Carbon Metal Pipe Tube | ||||||||

| Standard | API5L, ASTM A106 Gr.B, ASTM A53 Gr.B, ASTM A270, ASTM A249, ASTM A511,ASTM A778 ,ASTM A312,ASTM A358,ASTM A409,ASTM A213,ASTMA790,ASTM A268,ASTM A269,ASTM A554,ASTM B338,ASTM B673,ASTM B674,ASTM B677,ASTM B675, ASTM B676, Higher high quality Merge harvester areas harvester knife guard ASTM B690,ASTM A928,ASMEB36.19,ASMEB36.10,ASTMA179/A192/A213/A210/370WP91,WP11,WP2 | ||||||||

| GB5310-2009,GB3087-2008,GB6479-2013,GB9948-2013,GB/T8163-2008, GB8162-2008,GB/T17396-2009 | |||||||||

| EN15716-5,EN15717-7,DIN 17456,DIN 17458 | |||||||||

| JIS G3463,JIS G3119,JIS G3446,JIS G3218,JIS G3258,JIS G3448,JIS H4631 | |||||||||

| DEP 31,DEP forty,DEP 20,DEP 32,DNV-OS-F101 | |||||||||

| Grade | Q195 = S195 / A53 Quality A | ||||||||

| Q235 = S235 / A53 Grade B / A500 Grade A / STK400 / SS400 /ST42.2 | |||||||||

| Q345 = S355JR / A500 Grade B Quality C | |||||||||

| Size | five.8~12. m or as custom-made | ||||||||

| Surface Therapy | Primary high quality (bared, oiled, colour paint, 3LPE, or other anti-corrosive treatment) | ||||||||

| Inspection | With Chemical Composition and Mechanical Qualities Examination | ||||||||

| Dimensional and Visible Inspection, also with Nondestructive Inspection. | |||||||||

| Application | Composition, Electrical electricity transmission tower assignments, Piling, Drinking water, Oil & gasoline pipeline engineering, Mechanical market,Municipal assignments, Roadways and its auxiliary services, and many others. | ||||||||

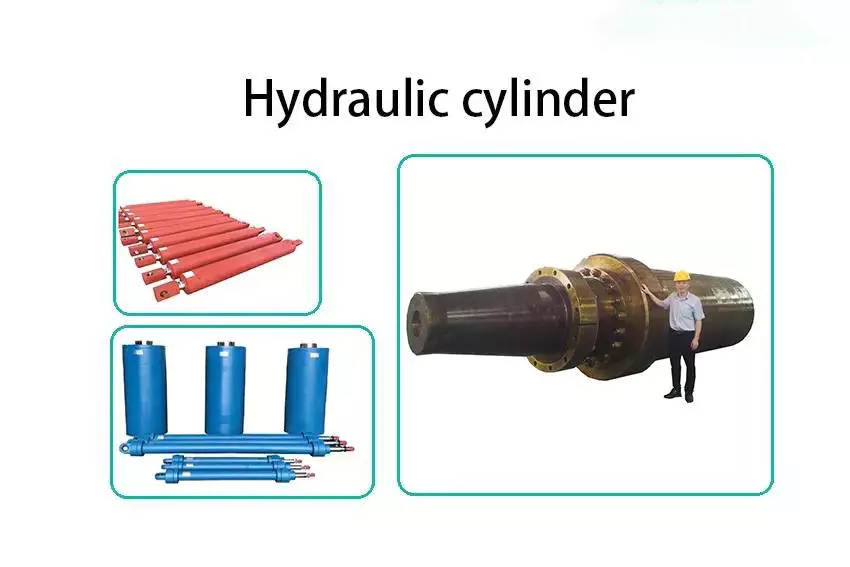

Choosing Hydraulic Cylinders

Typically, hydraulic cylinders are used in applications such as manufacturing machinery, construction equipment, and civil engineering. They are also used in elevators and other applications where the use of a mechanical actuator is necessary.

Piston seals

Choosing the correct piston seals for hydraulic cylinders can help to ensure the proper operation of the cylinder. Seals are designed to keep fluids and contaminants from flowing across the cylinder. However, external factors can affect their performance. In order to choose the right seals, it’s important to understand the different types.

There are two basic piston seal types. One is a double acting seal that maintains pressure on both sides of the piston. The other type is a single acting seal that maintains pressure on only one side of the piston.

Double acting piston seals are typically made of a slide ring. They maintain the pressure in a hydraulic cylinder and allow the ram to move in a controlled direction. The slide ring is normally made of a plastic material. However, it is important to select a material that is suitable for the fluid pressure that is expected.

Single acting cylinder seals are designed for cylinders where one side of the piston is under high pressure and the other side is under low pressure. These seals are usually designed to provide the best sealing characteristics.

In addition to the seal, it is important to select the right guide. A guide is a metal strip or ring that keeps the piston and the piston rod radially centered in the cylinder assembly. This guide also keeps metal-to-metal contact between the two components.

For high-pressure applications, it is recommended to use piston seals made from PTFE. These seals can withstand temperatures up to 800 degrees Celsius. They have less friction than rubber seals and are also resistant to abrasion. However, they are not as durable as thermoplastic elastomers.

The seals are designed to maintain a constant pressure for a longer period of time than other materials. In addition, they are resistant to tearing, and they stand up to high use.

Coatings for hydraulic cylinders

Various coatings for hydraulic cylinders are available in the market. The main purpose of these coatings is to provide protection against physical and chemical attacks. These coatings are usually applied externally or internally.

Plasma spray is one of the most common surface modification methods. It combines flame and arc spray to deposit metallic or ceramic materials onto the surface. This process improves the operating characteristics of actuators. It is also useful in repairing damaged surfaces.

Another popular surface treatment is liquid nitrating. It produces a hard iron nitride layer that has excellent surface hardness. It also provides a good surface resistance. It can be used as a thermal barrier coating on stationary gas turbine blades.

Hard chrome over nickel coating is also a common type of coating for hydraulic cylinders. It provides good corrosion resistance and abrasion resistance. It is plated onto the surface and then polished.

Another popular surface modification method is thermal spray. It uses engineered materials to deposit metallic or ceramic materials onto the surface. It is a cost effective solution to surface enhancement. It also eliminates the need for costly replacement parts.

In addition, WC-CoCr coatings provide good wear resistance and corrosion resistance. These coatings are particularly useful for parts that are subjected to harsh working conditions.

Ceramic plating is mostly used in the aerospace and military industries. It also reduces friction and provides heat shielding. It can also be used as an alternative to hard chrome coatings.

The most important mechanical properties are the hardness, yield strength and the tensile strength. The material selection should be based on the shape and dimensions of the object being produced. This article will discuss the most commonly used materials and give an overview of the most effective surface modification methods.

Double-acting cylinders

Basically, hydraulic cylinders are used in a variety of applications, including engineering, industrial furnaces, and lift shafts. They are also used in subsea environments, shipbuilding, and oil & gas.

A double-acting hydraulic cylinder is a type of hydraulic cylinder that combines the best features of a single-acting cylinder with some additional advantages. These benefits include higher force, greater flexibility, and more control. Double-acting hydraulic cylinders are generally used in high-powered applications, such as lift shafts, excavation equipment, and robotics. They are also used in mobile applications, such as earthmoving equipment.

The main difference between single acting and double-acting hydraulic cylinders is the way the piston is moved up and down the cylinder bore. Double-acting cylinders use hydraulic fluid to apply pressure on both sides of the piston rod.

Another advantage of double-acting hydraulic cylinders is their ability to extend and retract without the need for an external force. In contrast, single acting cylinders require an external source to move the piston.

Double-acting hydraulic cylinders are more expensive than single-acting cylinders. This is because they have a larger housing and require more dedicated maintenance. They are also more costly to buy.

However, they are also more accurate and efficient. Double-acting cylinders work faster and can be used in virtually any application. They are also better for industrial tasks, such as lifting merchandise off conveyor belts. They can also work in an angle, and they are suitable for mobile applications.

In addition to their performance, double-acting hydraulic cylinders are more likely to be ISO compliant than single-acting cylinders. They also offer more design options.

Depending on the needs of the application, a double-acting hydraulic cylinder may be more expensive than a single-acting cylinder. This is because the piston seal must be designed to work with the fluid. The seal material is generally rubber or a rubber/fabric composite.

Stainless steel cylinders

Stainless steel hydraulic cylinders are used in numerous industries. They are known for their durability and rust resistance. They are used in industrial hydraulics applications, as well as in the food and beverage processing industry. They also help processing facilities meet industry standards.

Stainless steel hydraulic cylinders are made of a stainless steel alloy that contains at least 10% chromium. The chromium oxide forms a thin layer on the steel’s surface, contributing to its corrosion resistance. The alloy also develops a non-porous surface that prevents bacteria from lingering. It also contributes to the steel’s ability to self-repair.

Stainless steel hydraulic cylinders are widely used in the food and beverage processing industry. They are particularly useful for moving heavy loads. They can withstand frequent cleaning operations. They also provide excellent strength. They are commonly used in chocolate molding machines and cold press juicers.

Stainless steel hydraulic cylinders are available from Maverick Machine & Hydraulics. They can be customized to meet your specifications. They can be manufactured with a satin finish or a streamlined design. They can also be custom colored. The manufacturer will provide full service and a competitive price.

Hydraulic cylinders are used to push, pull, or push-pull heavy loads. They are designed to withstand extreme temperatures. They are also available in single and double-acting configurations. They are commonly used in pharmaceutical, food, chemical, and marine applications. They are also used on coastal power generation plants and pipeline risers. They are also used in water treatment plants. They can also be used on oil platforms.

There are two types of hydraulic cylinders, which are single-acting and double-acting. The single-acting type has a single fluid chamber, while the double-acting model has more fluid in the pressurized chamber. The single-acting cylinder is more affordable to maintain and easier to control.

Pivot rod style cylinders

Choosing hydraulic cylinders requires a great deal of attention to detail. You will need to consider the following factors: cylinder length, rod size, rod seals, bearing loads, and the type of cylinder you need.

Hydraulic cylinders are used in a variety of applications, such as lifting and lowering buckets, as well as jack knifing and metal sheet shearing machines. They are also used in hydraulic bending machines and earth-moving equipment.

The main sleeve or barrel of a hydraulic cylinder extends to its maximum stroke. It can be either single or double acting, and can be either stationary or pivoting. This allows a cylinder to move a load in a straight line or a circular path.

Cylinders have a variety of mounting styles, including clevises, flanges, and side mounts. Flange mounts are generally used in force-transfer applications where the cylinder must be parallel with the load. Flanges come in several shapes and sizes, including a square flange, a rectangular head, or a cap. Aside from transferring load, they also absorb force along the cylinder centerline.

Cylinders have a variety and range of seals, which are used to prevent hydraulic fluid leakage past the interface. These seals are made of various materials, including metal and elastomeric seals. The materials used for these seals depend on the application. These seals also vary in terms of pressure, temperature, and temperature changes.

Clevises and flanges are two common mounting styles for hydraulic cylinders. They are used to provide structural support for bolts. These mounts also work to absorb force along the cylinder’s centerline. These mounting styles have less rod bearing loads than other types, but they must be properly aligned with the load.

editor by czh 2023-07-03