Condition: New

Warranty: 6 Months

Relevant Industries: Machinery Fix Retailers, Retail, Design works

Bodyweight (KG): 200

Video clip outgoing-inspection: Offered

Equipment Check Report: Not Offered

Advertising Type: New Product 2571

Guarantee of core elements: 6 Months

Main Factors: Stress vessel

Standard or Nonstandard: Normal, Standanrd

Composition: Piston Cylinder, Piston Cylinder

Power: Hydraulic

Physique Materials: Metal

Product name: excavator hydraulic cylinder

Seal: High top quality or as required

MOQ: 1pcs

Surface area Remedy: Chrome Plated .02-.03mm

Coloration: blue

Material: 20#/45# Steel

Payment: TT.Money Gram.Western Union. Paypal

Shipping and delivery time: In 7 days

Packaging Details: Wood containers, picket pallets, straw ropes or negotiated with consumers.

Port: Xihu (West Lake) Dis. Port, HangZhou, ZheJiang , China, or in consultation with consumers

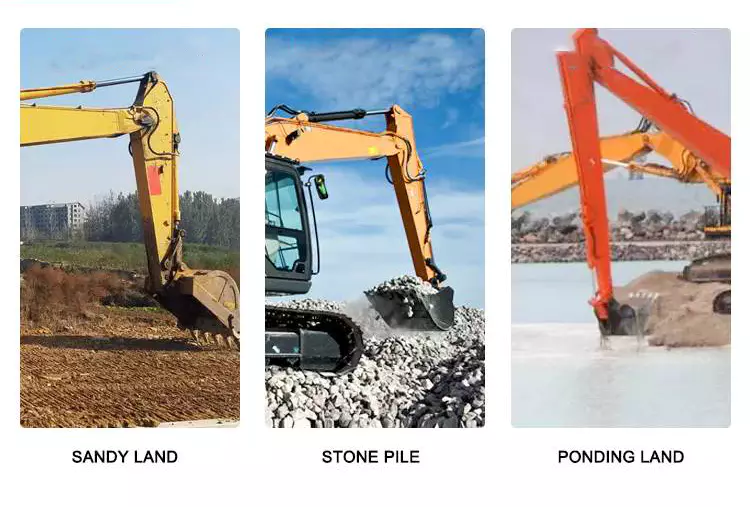

hydraulic cylinder manufacturing excavator arm boom bucket cylinders for excavator Factory direct sale for excavator hydraulic cylinder assembly, bucket cylinder, 3-period Induction 3 Period Brushless Y2 Series 3-period AC Electrical Motor arm cylinder, increase

cylinder, cylinder tube, piston rod, cylinder head/handles, piston,nut ,seal kits.

| Assembly unit | Materials | Procedure characteristics |

| Piston Rod | 40Cr | Hardening and tempering with heat therapy ,difficult chrome plated,mirror polishing |

| Cylinder Barrel | 25Mn | Tempering warmth treatment method to anti-deformation,25Mn is a lot more bearable than C45/C20 metal |

| Barrel/rod conclude, Barrel/rod head | Toughness steel | Cast high toughness metal |

| Seal Kits | NOK, On the internet Wholesaletor NG0321225260-A Trailer Components & Components Axle Hub Dust Cap SKF | Lengthier daily life and seal effect |

| Bushing | Hardened steel or copper |

Obtainable excavator brand

| KOMATSU | VOLVO | SUMITOMO | LIEBHERR | HITACHI | DOOSAN | HYUNDAI |

| KOBELCO | CATERPILLAR | KATAO | SANY | XCMG | Situation | KUBOTA |

Thorough photos

Business InformationHangZhou CZPT ENGINEERING Machinery CO.,LTD is a modernized producer that concentrate on R&D,producing and marketing excavator hydraulic cylinders.Our firm addresses an location of twenty,000 square meters,with far more than 50 employees and 6 department places of work.More than ten many years of steady expansion,our hydraulic cylinders have been exported to South-East Asia, Mid-East, South The us,Africa,and many others.

Our exhibition

Other merchandise

Packaging & Delivery

Our Solutionsone. OEM Producing welcome:Product, Stepper Motor Kit Higher Torque 3NM fifty seven Hybrid 2-stage Nema 23 Shut-Loop Stepper Motor with Driver Package deal,or custom-made.2. Sample purchase accessible.three. We will reply you for your inquiry in 2 several hours.four. Soon after sending,we will track the merchandise for you when every 2 times,till you getthe merchandise.When you got the items,take a look at them,and give me a comments.If you have anyquestions about the difficulty,make contact with with us,we will offer you the remedy way for you.5. Source to Southeast Asia,the Center East,Africa,Europe,and Austrillia.6. Professional Excavator Hydraulic Cylinder Provider.seven. Technician Assist.

Get in touch with us

The Basics of Hydraulic Cylinders

Basically a hydraulic cylinder is a mechanical actuator which can be used for giving unidirectional force. It has various applications in civil engineering, construction equipment, manufacturing machinery and elevators.

Single acting vs double acting

Generally speaking, single acting and double acting hydraulic cylinders function differently. Double acting cylinders have two ports, and apply pressure on both sides of the piston. Single acting cylinders have a single port.

Hydraulic cylinders are used in a wide variety of applications, including manufacturing machinery, construction equipment, and civil engineering. Their main use is on mobile equipment such as graders and excavators. They are also used in reciprocating engines and hydraulic rams.

Single acting hydraulic cylinders are generally smaller and more compact than double acting cylinders. They are also simpler in design and require less maintenance. They are suitable for heavy-duty applications such as lifting and ejecting parts from conveyor belts. They are also cheaper to manufacture. However, they have a limited range of motion, and have limited power and control.

Double acting cylinders, on the other hand, offer more flexibility, faster operation, and greater power. They are also better suited for applications that require precise retraction control. They are more durable than single acting cylinders, and are commonly used in heavy industrial applications. They also have more design variation.

In order to determine whether you need a single acting or double acting cylinder, you should first consider your power requirements. Single acting cylinders are better suited for applications that require only a small amount of force, but require several stroke cycles. Double acting cylinders are suited for applications that require more force, but require a higher number of stroke cycles.

Single acting cylinders are more economical to buy and install, but they are not as compact as double acting cylinders. They are also not as reliable as double acting cylinders. In addition, they may require a second port to convert a single acting cylinder into a double acting cylinder.

Piston rod

During the design phase of a hydraulic cylinder, many factors must be considered. These include the function, materials, and the environment in which the cylinder will be used.

The most important part of the hydraulic cylinder is the rod. It performs the reciprocating motion and is attached to the piston by threads. It also acts as the structural component of the cylinder.

The rod itself is made from chrome plated steel and is usually 10 to 30 millimeters thick. It is plated with a thick layer of chromium to increase wear resistance and temperature resistance. The rod also has an o-ring on its end to prevent the high-pressure oil from escaping.

The rod is connected to the piston by a backup ring and two o-rings. The o-rings keep the rod centered in the barrel, while the backup rings protect the o-rings from escaping when high pressures are applied from the opposite side.

The most important feature of the piston rod is its buckling resistance. The rod may be solid, hollow, or heat-treated. The buckling resistance of a rod depends on its length and its diameter. The longer the rod, the less force it needs to withstand a buckling load.

Another important feature of the rod is its slenderness ratio. This ratio is calculated by measuring the effective length of the rod. This ratio is usually calculated by using Euler’s theory.

The cylinder head is another important part of the hydraulic cylinder. The head has ports that allow hydraulic fluid to enter and exit the barrel. It also has a check valve to prevent oil from leaking out.

The cylinder head also serves as a mechanical stop for the piston. It has two seals: a gland seal and an internal seal. The gland seal prevents the high-pressure oil from escaping, while the internal seal ensures that the o-ring seal is in place.

Welded body vs flanged connection

Generally, there are two kinds of connections for hydraulic cylinders: flanged and welded body. The flange connection is usually used in applications where there is exceptionally high pressure. A welded body connection can be used in places where space is limited. It also improves the overall appearance of the equipment.

Hydraulic cylinders are used in a variety of applications, including earth moving equipment, metal sheet shearing machines, and hydraulic bending machines. They are also used in particle board making hot press machines. The majority of hydraulic cylinders are made from alloy steel combinations.

These materials are prone to rusting, especially when used in humid environments. They may also require coating to prevent corrosion. Hydraulic cylinders can be made of stainless steel or alloy steel. Stainless steel is usually used in marine environments because of its corrosion resistance.

Hydraulic cylinders come in a variety of designs, including single acting cylinders, double acting cylinders, and telescopic cylinders. Single acting cylinders are designed for pushing motion, while double acting cylinders are designed for a linear motion. They are available with threaded, socket weld, or welded body connections.

The rod of a hydraulic cylinder operates outside of the barrel, pushing hydraulic fluid inside the barrel. The piston rod needs to be protected from wear, and the outer diameter of the piston rod is usually coated with a corrosion-resistant surface.

Hydraulic cylinders are typically made of carbon steel, stainless steel, or alloy steel. There are a variety of coatings available, including chrome (nickel) plating, laser cladding, and hard chrome plating.

The most important seal in hydraulic cylinders is the rod seal. This seal needs to be slow to wear, and it needs to be able to resist multiple rod movements. It must also be able to remove contaminants from the hydraulic fluid.

Pneumatic actuators vs hydraulic actuators

Compared to hydraulic actuators, pneumatic actuators are cheaper and less powerful. However, they offer higher uptime and increased productivity. This makes them a good choice for light to medium duty applications.

Pneumatic actuators use air pressure instead of hydraulic fluid, and they provide a reliable motion that is ideal for window manufacturing. They have a simple design that reduces maintenance. They can be used in various applications, including food production, automotive manufacturing, and industrial machinery.

Hydraulic actuators are better suited for heavy duty applications. They can handle higher pressures and generate more force than pneumatic actuators. But they can leak fluid, which can invite contamination. They can also be noisy, without the use of noise-reducing equipment.

Hydraulics also require pumps and reservoirs for fluid. There are also valves, pistons, and companion parts to maintain the system. It is important to check for leaks and maintain the system.

Hydraulic actuators are used in heavy construction equipment, nail guns, precision drills, and moving machinery. Hydraulic cylinders provide 25 times the force of pneumatic cylinders.

Hydraulic systems can be a good choice for heavy duty applications, but they can also cause more problems. For example, the pressures can be very high, and they can leak fluid. Hydraulics require regular maintenance, which increases the overall cost of ownership. They can also lead to contamination of the internal working parts of the system.

The biggest advantage of hydraulic actuators is their ability to create and hold torque. It’s important to monitor the temperature of the fluid to avoid leaks. If there is a leak, the fluid can be contaminated and damage internal working parts.

Hydraulic actuators require more care and maintenance, and they may be more expensive than pneumatic actuators. The cost of maintenance may also affect the lifespan of the device.

Cushioned vs non-cushioned cylinders

Depending on the application, cushioned hydraulic cylinders can be used as a cost-effective and useful tool for reducing shock loads. The cushioning can take a variety of forms, from external shock absorbers to internal cushions.

Cushioning is the process of decelerating the cylinder rod near the end of its stroke. This reduces vibration and reduces stresses on components. However, too much cushioning can reduce the efficiency of the machine, especially for pneumatic cylinders.

The cushioning effect is achieved by restricting the flow of hydraulic fluid exiting the cylinder port. This is achieved through a small orifice that allows the flow to be controlled. The smaller the orifice, the more controllable the cushioning effect.

A typical example is a double-acting cylinder with double-sided cushioning. The cylinder is constructed with a check valve oriented from port A to port B. This valve is set to operate from a minimum of 10 millimeters before the end of the stroke.

The cushioning effect can be regulated externally with an adjustable screw. In order to determine the amount of cushioning required, it is important to consider factors such as cylinder size, stroke, and application.

In addition to being able to control the flow of hydraulic fluid, the cushioning effect can also be used to protect the entire system. It can be used to restrict the exiting flow of hydraulic fluid so that the incoming flow can reach maximum pressure.

Cushioning can be used in conjunction with other methods to reduce shock loads. For example, a fast start-up method can reduce the impact force of the cylinder. A cushion design can also increase the rate at which fluid returns to the cylinder when it leaves the cushion.

editor by czh 2023-07-03