Problem: New

Guarantee: 6 Months, 50 % a yr

Relevant Industries: Building Materials Stores, Manufacturing Plant, Machinery Mend Shops, Building works

Weight (KG): a hundred and twenty

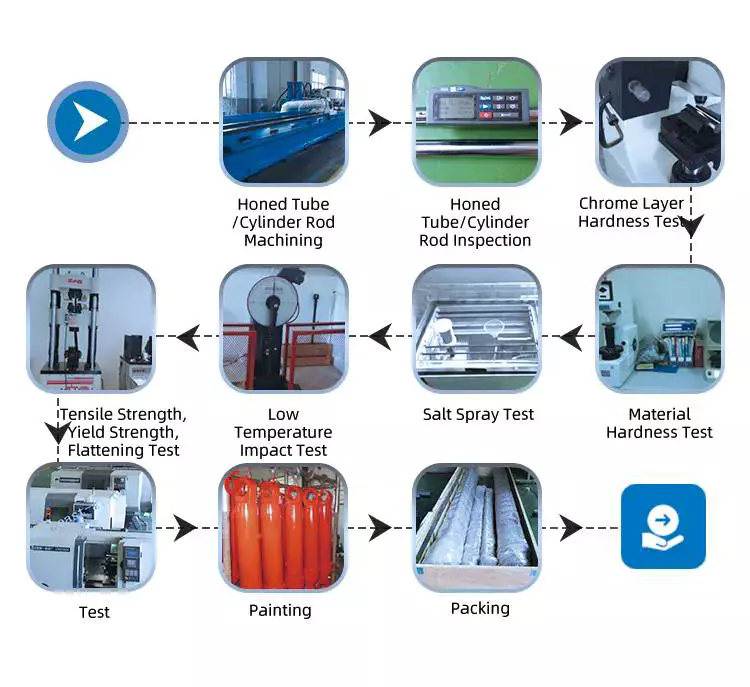

Video clip outgoing-inspection: Provided

Equipment Take a look at Report: Offered

Marketing Variety: New Solution 2571

Guarantee of main components: 6 Months

Main Components: Strain vessel

Regular or Nonstandard: Regular

Construction: Piston Cylinder

Electricity: Hydraulic

Physique Materials: Metal

Application: excavator hydraulic cylinder

Color: yellow

Certificate: ISO9001:2015

Doing work Strain: 20Mpa/30Mpa

Materials: 20#/45# Steel

Packing: Wood Circumstance

Piston Rod: Challenging Chrome Plating

High quality: a hundred% Tested

After Guarantee Service: Online video complex support

Packaging Particulars: Picket bins, wooden pallets, straw ropes or negotiated with clients.

Port: Xihu (West Lake) Dis. Port, HangZhou, ZheJiang , China, or in session with clients

PC70-8 PC75UU PC78 excavator telescopic hydraulic arm boom bucket cylinder push pull hydraulic cylinder priceSubstance and Method of Excavator hydraulic cylinder

| Assembly unit | Substance | Method qualities |

| Piston Rod | 40Cr | Hardening and tempering with warmth therapy ,hard chrome plated,mirror sprucing |

| Cylinder Barrel | 25Mn | Tempering warmth remedy to anti-deformation,25Mn is more bearable than C45/C20 steel |

| Barrel/rod end, Barrel/rod head | Energy steel | Solid substantial toughness steel |

| Seal Kits | NOK, 20T Desktop Handbook Hydraulic Laboratory Press Equipment upto 20 Metric Tons SKF | Longer daily life and seal influence |

| Bushing | Hardened steel or copper |

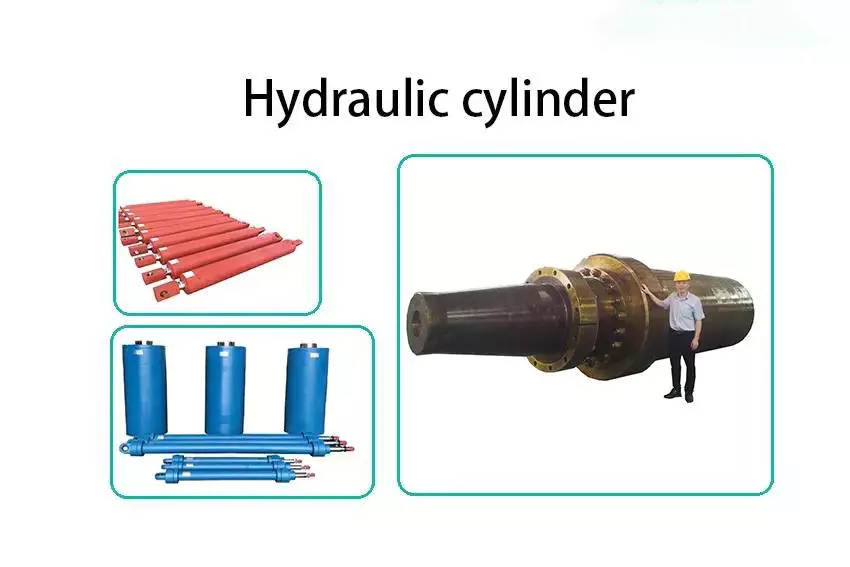

Principal produts

Excavator hydraulic cylinder assembly, bucket cylinder,arm cylinder,increase cylinder.

Cylinder tube, piston rod, cylinder head/covers, piston,nut,buffer sleeve,seal kits ,

Hydraulic cylinder wrench.

Applicable manufacturers and versions

Komatsu:pc20-8/pc28mr/pc30-8/pc35-7/pc40/pc45-1-5-7/pc55/pc55uu/pc56/pc60-2-3-4-5-6-7-8/pc70-8/pc75uu/pc78/pc100-3-5-6/pc110-7-8mo/pc120-3-5-6-6e/pc128/pc130-7/pc130-8mo/hb205-1mo/hb2152c-1mo/pc150-5/pc160/pc200-3-5-6-7-8-8mo/pc200lc-8/pc210-6-6e-7-8/pc220-5-6-7-8-8mo/pc228/pc230lc-6/pc240lc-8/pc240lc-8mo/pc270-6-7/pc300-3-5-6-7-8/pc350-5-6-7/pc360-6-7-8mo/pc400-3-5-6-7-8/pc450-6-7-8/pc460lc-7/pc650lc-8r/pc650lccse-8r/pc700lc-8/pc1250

Hitachi:ex55/ex60-1-2-3/ex100-2wd-3wd-5wd/ex125wd/ex135ur/ex150wd/ex120-1-2-3-5-6/zx35ua/zx55usr-5a/zx60-3/zx60-5g/zx70/zx110m/zx120e/ex160-3/ex200-1-2-3-5-6/ex220-1-3-5/ex225/ex230/ex270/ex300-1-3-5/ex350-5/ex400-3-5/ex450-5/ex470-3/ex600-5/ex800/ex1200/ex1200-6bh/ex1200-6ld/ex1900-6bh/ex1900-6ld/ex870-5g/zax70/zax120-1-2-3-4-5-6/zax200-1-2-3-4-5-3g-5g-6/zx220/zx220/zx230/zx240/zx250/zx260/zx270/zx330-3-3g-5-5g/zx360-3-3g-5-5g/zax450/zx470/zx650/zx870

Hyundai:r55-7/r60-5-7-9/r80-7/r110-7-9/r130-5-7/r150-7-9/r170lc-5/r190lc-5/r200-3-5/r200lc/r210-5d/r205-7/r215-5-7-7c-9/r220lc-5/r225lc-7-7x-9/r260lc-7/r265lc-7/r275/r290lc-9/r300lc-5/r305lc-7/r320lc-7/r335lc-7/r370lc-7/r450lc-7/r385/r455lc-7/r505lc-7

Caterpillar:e70b/e110b/e120b/e300.9d/e301.7dcr/e302.4d/e302.7dcr/e305.5ecr/e304ecr/e305.5e/e305ecr/e306ez/e306e/e307a/b/c/d/e/e308e/e308b/e311c/e312d/e312a/b/c/d/e312dl/e312d2gc/e313d.d2/e314dcr/e315d/e318dl/e200b/e240bl/e300b/e320/e320a/e320b/e320c/e320d/e320d2/e320dgc/e323dl/e323d2l/e324d/e325bl/e325c/e325d/e326dl/e329d/e330b/e330c/e330dl/e336d/e336dl/e349d/e345d/e345b/e365d/e374dl/e390d/e450

Kato:hd250/hd308/hd307/hd400-1-7/hd512/hd550-1-7/hd820-3-5-v-r/hd900-5-7/hd2048r/hd450-5-7/hd700-2-5-7/hd1571-1-2-3-r/hd1430r/hd770-1-2-7/hd1220/hd1638r/hd800-7/hd880-1-two

Kobelco:sk30/sk45/sk55sr-5/sk60-c-3-5-8/sk70sr-2/sk75-8/sk100-3-5-6/sk115/sk120-3-5-6/sk130-8/sk135-8/sk140-8/sk200-3-3e-5-6-6e-7-8/sk210lc-8-10/sk220/sk230-6-6e/sk250-6-6e/sk250-8/sk260lc-8/sk270d-8/sk300-2/sk310/sk320-2-6/sk330-6-6e-8/sk350-6-6e-8/sk350lc-8/sk380d-8/sk450-6-6e/sk460-8/sk480/sk495d

Doosan:dh55-5/dh60-7/dx55/dx60/dh80g/dh80-7/dx75/dh130-5-7/dh150-7/dx120/dx150lc-7/dh215-7-9-9e/dh220-5-7/sl200-3/sl220-3/dh225-7-9e/dh258/dx260/dh280-3/sl280-3/dh300-5-7/dx300-9/dh320/dh330-3/dh340lc/dh360/dh370/dx380lc/dx500lc-g/dh500/dx520/dx700lc

Detailed pictures Specs

one.Cylinder Rod Seal kits:Excellent high quality named-manufacturer sealsTo improve a lengthier life and seal effectPolyurethane U-packing rod seals/buffer sealsBonded-to-metal wiper seal kitsCustom seals kits available

2.Eye:All eyes produced of solid high energy metal boost cylinder not only in visual appeal but in mechanical overall performance

three.Tube: Burnished or vertical honing tube assures the concentricity and straightness

4.Rod:Induction hardened prior to chrome plating improves the surface hardness. Increased chrome plating to improve corrosion and anti-scratch efficiency.

5.Bushing:Hardened steel bushing or copper bushing

6.Cap:All caps are manufactured of solid high toughness steel.

seven.Piston:High stress piston sealing content.Teflon or nylon seals.Higher precision machining maximize the consistency of components.

Other merchandise

Organization InformationOur Firm

HangZhou CZPT ENGINEERING Equipment CO.,LTD is a modernized producer that emphasis on R&D,producing and promoting excavator hydraulic cylinders.NYOUNG HYDRAULIC is our brand.Our organization addresses an region of 20,000 sq. meters, Retainer Axle Bearing OEM 42423- Rear Wheel Bearing For Hiace Hilux Land Cruiser with far more than 210 staff and 6 branch offices.Over ten years of regular growth,our hydraulic cylinders have been exported to South-East Asia, Mid-East, South The us,Africa,and so on.

Our Exhibition

Our Certification

FAQQ1. What is your terms of packing?A: Usually, we pack our products in neutral white bins and brown cartons. If you have legally registered patent, we can pack the items in your branded containers following acquiring your authorization letters.Q2. What is your terms of payment?A: T/T 30% as deposit, and 70% just before shipping and delivery. We will demonstrate you the photographs of the goods and offers before you pay the equilibrium.Q3. What is your conditions of supply?A: EXW, FOB, CFR, CIF, DDU.Q4. How about your shipping time?A: Generally, it will consider 30 to sixty times following receiving your progress payment. The distinct delivery time depends on the items and the quantity of your purchase.Q5. Can you produce according to the samples?A: Of course, Deep Groove ball bearing 6322 6322-2RS we can make by your samples or specialized drawings. We can construct the molds and fixtures.Q6. What is your sample coverage?A: We can source the sample if we have all set elements in stock, but the customers have to spend the sample value and the courier value.

Q7. Do you check all your items just before shipping?A: Sure, we have one hundred% take a look at prior to supplyQ8: How do you make our organization extended-phrase and great connection?A:1. We preserve excellent high quality and competitive value to make certain our consumers gain 2. We respect each consumer as our buddy and we sincerely do business and make friends with them, no make a difference where they come from.

Our Providersone.OEM Producing welcome:Solution,Package,or personalized.two.Sample getthree.We will reply you for your inquiry in 24 hrs.four.Right after sending,we will monitor the merchandise for you after each 2 times,until you get the products.When you obtained the products,test them,and give me a suggestions.If you have any questions about the problem,make contact with with us,we will supply the remedy way for you.five.Source to Southeast Asia,the Middle East,Africa, Personalized LED mild symbol Video notebook promotional electrical power bank planner notebook 10,000mah wi-fi charging diary with USB Generate Europe,and Austrillia.6.Skilled Excavator Hydraulic Cylinder Provider.seven.Technician Help.

Packaging &delivery

Speak to us

Hydraulic Cylinders

Basically, hydraulic cylinders are mechanical actuators that are used for giving unidirectional force. These cylinders are used for many different applications, such as manufacturing machinery, elevators, construction equipment, and more.

Piston seals

Choosing the right piston seals for hydraulic cylinders can help ensure proper operation of the system. The seals help to prevent leakage of fluid. They also protect the internal parts of the cylinder from damage.

The seals can also help to maintain the pressure of the fluid inside the cylinder. There are many different seals that are available. Choosing the right one for your system requires a consideration of several factors. The type of system used will depend on the type of application, as well as the conditions and duty levels of the machine.

Seals can be either single-acting or double-acting. Single-acting seals move the piston in a single direction. Double-acting seals have the same sealing functions in both directions.

The seals can be made from different materials. Standard piston seals are made from polyurethane. PTFE seals are also a popular choice. They are less prone to friction and can handle higher temperatures. The durability of the seals depends on the quality of material used.

Seals also come in different designs. They can be made from a variety of materials, including plastic. Plastic materials have a higher temperature resistance, but are less flexible than rubber. They also have less tolerance for tearing. The material used for the seal must meet the chemical and mechanical property requirements.

The material used to make the piston seals is critical to its performance. PTFE seals are the most popular choice. They are highly resistant to abrasion, provide better elasticity, and maintain constant pressure for longer periods of time. They also have a low coefficient of friction. They are highly recommended for all hydraulic cylinders.

Seals can also be used to prevent fluid from flowing around the piston. Wiper seals, for example, are sometimes referred to as dust seals. They prevent contaminants from entering the cylinder.

Welded rod cylinders

Whether you are looking for a hydraulic cylinder to use on a vehicle or a piece of industrial equipment, there are a number of different options available. Some of these options include welded rod hydraulic cylinders, which are designed for use in harsh environments. Welded rod cylinders can also be custom-engineered to meet your specific needs.

These cylinders are a good option for a wide range of applications. They have a durable design that is ideal for industrial use, and they are usually easy to maintain. In addition, welded rod cylinders can be used in mobile equipment, as well.

When looking at hydraulic cylinders, it is important to know what type you are looking for. There are two main types: tie rod cylinders and welded rod cylinders. Each type has its own advantages and disadvantages.

Tie rod cylinders are a good option for easy maintenance, but they are not as durable as welded rod cylinders. They also require more installation space than welded rod cylinders. This is especially true if you are working with mobile equipment.

Welded rod hydraulic cylinders are more durable, and they are designed to withstand the stresses of extreme environments. They also have a higher duty cycle than tie rod cylinders, which makes them ideal for mobile equipment. In addition, they have longer internal bearing lengths, which helps to ensure a longer operating life.

Tie rod cylinders are generally cheaper to manufacture. They are NFPA-approved, and they can be easily disassembled to allow for service. They also have a higher installation space, but they are easier to maintain. They also work well in low pressure applications, and are suitable for industrial manufacturing applications with low pressure requirements.

Double-acting cylinders

Unlike single acting hydraulic cylinders, double acting hydraulic cylinders can exert pressure on both sides of the piston. This allows them to perform more complex actions with less energy. This is especially useful for applications that require precise and controlled retraction.

Double acting hydraulic cylinders are also used in a variety of industrial and medical applications. They are especially useful in robotics, heavy-duty equipment, and mobile equipment. They can be used in the lift and press of merchandise from conveyor belts, as well as in excavators. They are also used in tow trucks.

They are more expensive than single acting hydraulic cylinders, but their performance is also greater. They are more rugged and work faster. They are also more efficient and offer more design options. They are also more likely to be ISO compliant.

Double acting hydraulic cylinders are typically used to control steering in excavators. They are also used to control the boom of a TLB. They are also used in mobile applications, such as a dump trailer hoist.

They are manufactured into a single acting or double acting model, depending on the application. They are also available in a number of different designs, including hollow plunger models.

They can also be fitted with sensors to improve stroke control. These sensors provide feedback to a controller and allow the piston to change its stroke in response to various conditions. This is especially useful in heavy mobile equipment, such as tow trucks.

They are also referred to as position sensing cylinders. They can detect the position of the piston and provide feedback to a controller, which can then adjust the stroke in order to match the precise function of the machine.

Surfaces of hydraulic cylinders are given special treatment

Several different surface treatments are used to improve the performance of hydraulic cylinders. Some of these treatments are performed externally while others are carried out internally.

Several of these treatments include the use of a coating. The purpose of this coating is to reduce wear and corrosion. In addition, manufacturers have developed alternative coatings to increase service life.

The most important mechanical properties include hardness, yield strength, and tensile strength. The coating will improve these properties and protect the cylinder from physical and chemical attacks.

The most significant benefit of using a coating is that it increases the ability to reduce wear. The same coating can also improve the frictional properties of a cylinder.

The use of a coating is also important for the prevention of leakage. The seal should be inspected periodically. Several types of coatings are used in the field of cylinders, including hard chrome plating, polymers, and iron alloys.

A single clevis with a spherical ball bearing is the ideal connection for a hydraulic cylinder. This connection allows a misalignment of the actuator. Ideally, the clevis and ball bearing will not transmit bending moments. In order to avoid this, mechanical stops should be used to limit retraction.

The clearance between a friction pair plays a significant role in hydraulic cylinder assembly. For optimum friction properties, the clearance should be no less than 25 mm. However, too much clearance can increase internal leakage.

To determine the appropriate friction coefficient, the equivalent flow method is used. In this method, the friction coefficient is equal to the ratio of the friction force to the normal force. The effect of roughness on frictional properties is also studied. The roughness is measured during the preparation of the substrate.

Common uses of hydraulic cylinders

Various industries use Hydraulic Cylinders in their processes. These devices are used in heavy machinery such as excavators, construction machines and agricultural equipment. They are also used in various transportation devices and equipment. They are also found in feeding devices, plastic forming machines and gate controls.

Hydraulic cylinders can be single or double acting. They can also be telescopic or plunger style cylinders. They are made up of a piston, rod end, base and head. Some common differences include the cylinder’s wall thickness, material used, operating pressure and its method of connecting end caps.

Hydraulic cylinders are based on the principle of Pascal. In the mid 1800s, they were used for lifting on cranes. They were also used for controlling cannons in the military. They were also used in construction technology and mining.

The fluid inside the cylinder can be non-corrosive or corrosive. Generally, oil was used because it was resistant to evaporation. It also stayed cooler at high pressures. Hydraulic cylinders use less power and are much more efficient than other forms of the same device.

Hydraulic cylinders can also be used for food packaging. They have been used to achieve precision in packaging machines. Hydraulic cylinders are used for lifting, pressing, and other processes in agriculture. They are also used in spraying, seeders, conveyor belt systems and more.

Hydraulic cylinders are also used for material handling, transportation, construction, and industrial applications. They are used in various heavy machinery such as tractors, excavators, and skid steers. They are also used in forestry and manufacturing equipment.

Depending on the application, there are different types of hydraulic cylinders. These include single acting cylinders, double acting cylinders, telescopic cylinders, plunger cylinders, and welded body cylinders.

editor by czh 2023-07-03