Product Description

|

Product Name |

Hydraulic Cylinder |

||||

|

Work Press |

7/14/16/21/31.5MPa 37.5/63MPa Can be Customized |

||||

|

Material |

Aluminum,Cast Iron,45mnb Steel,Stainless Steel |

||||

|

Bore Size |

40mm–320mm,Customizable |

||||

|

Shaft Diameter |

20mm–220mm,Customizable |

||||

|

Stroke Length |

30mm–14100mm,Customizable |

||||

|

Rod Surface Hardness |

HRC48-54 |

||||

|

Paint Color |

Black,Yellow,Blue,Brown,Customizable |

||||

|

Mounting |

Earring,Flange,Clevis.Foot, |

||||

|

Warrenty |

1 Year |

||||

|

MOQ |

1 Piece |

||||

|

Delivery Time |

7-15 Days,Also depands on specific demands |

||||

|

|

series |

) |

type |

model |

|

|

Komatsu series PC |

Upper arm, middle arm and lower arm |

PC120-6 PC130-7 PC130-8 PC200-5 PC200-6 PC200-7 PC200-8 PC200-8MO;PC220-7 PC240-8MO PC270-7 PC360-8MPO PC400-6 PC450-7 PC650 PC700-8 PC850 |

|||

|

Hitachi (Ex) series |

Upper arm, middle arm and lower arm |

EX120-5 EX200-1 EX300-5 EX450 |

|||

|

Hitachi (Zax) series |

Upper arm, middle arm and lower arm |

ZAX120 ZAX200/210 ZAX200-3G ZAX200-3/210-3 ZAX230/240 ZAX240-3G ZAX250-3/240-3 ZAX270-3 ZAX330 ZAX330-3G/360-3G ZAX450/ZAX470 ZAX670-3 ZAX870 ZAX1200 |

|||

|

Carter Series E |

Upper arm, middle arm and lower arm |

E315D E200B E320B E320C E320D E323D;E320GC E320D2 E324/E326D E325D E328D E329D E330C E330D E336D E345C/345D/347D/349D E365D/374D E385C E390D |

|||

|

Shengang series sk |

Upper arm, middle arm and lower arm |

SK120-5-6 SK200-6E SK200-8 SK210-8 SK230-6E SK250-6E SK260- 8 SK330-8 SK350;SK460-8 SK480-8 SK850-8 |

|||

|

Sumitomo series sh |

Upper arm, middle arm and lower arm |

SH120 SH200A3 SH210-5 SH240-5 SH350-3 /300-5 SH350-5 SH350-6 SH450-5 SH460-5 |

|||

|

Case series CX |

Upper arm, middle arm and lower arm |

CX210A CX210B CX240B CX350A CX360B |

|||

|

Modern series R |

Upper arm, middle arm and lower arm |

R130-7 R150-9 R200-5 R210-5 R215-7 R215VS R225VS R220-7 R225-7 R220LC-5 R210-9/215-9/225-9 R260-5 R267-7 R275-7 R275-9 R290LC/290-3 R305-7 R335-7 R370-7/R375-7 R455-7 R485-9 |

|||

|

Yu (Doosan DX) series DH |

Upper arm, middle arm and lower arm |

DH150 DH225-7 DH220-5/7 DX225-9 DH258 DH300-5/7 DH360 DH370 DX380 DH420-7 DH500G DH500-7 DH700 |

|||

|

Volvo series EC |

Upper arm, middle arm and lower arm |

EC140 EC210B EC240B EC290B EC360B EC380B EC460B EC480C EC700B |

|||

|

Three series sy |

Upper arm, middle arm and lower arm |

SY135 SY205/210/215-8/9 SY235C-8/-9 SY305/330/335-8/-9 SY360C/365-8/-9 SY385C-8/-9/405 SY465C-8/-9 SY600 |

|||

|

|

Upper arm, middle arm and lower arm |

C 230C 270DK 370C/375 470C 700 |

|||

|

Liugong series |

Upper arm, middle arm and lower arm |

915D 920D 920E 922D 922E 925D 926E 933E 936C/936D 945E |

|||

|

Longgong LKG |

Upper arm, middle arm and lower arm |

LKG6150 LKG6210/6215 LKG6225H LKG6230 LKG6270;LKG6360 |

|||

|

Temporary series |

Upper arm, middle arm and lower arm |

||||

|

Zoomlion Ze |

Upper arm, middle arm and lower arm |

ZE210E ZE230E ZE330E ZE480E |

|||

|

Garten series |

Upper arm, middle arm and lower arm |

HD700-5/7 HD820-3 HD1571 HD1430-3 HD1250-3 HD2045-3 |

|||

|

Yuchai YC |

Upper arm, middle arm and lower arm |

135 210-8 230-8 360-8 |

|||

|

Lovol fr |

Upper arm, middle arm and lower arm |

FR150 FR210 FR210-7 FR220 FR260 FR330 FR370 |

|||

|

Shanhe intelligent swe |

Upper arm, middle arm and lower arm |

SWE150 SWE210 SWE230 SWE330-8/360-8 SWE470 |

|||

|

Rexroth |

Upper arm, middle arm and lower arm |

|

|||

|

Xiagong XG |

Upper arm, middle arm and lower arm |

E 833/836 836E |

|||

|

SHangZhou JCM |

Upper arm, middle arm and lower arm |

JCM921D JCM922D JCM923D JCM924D JCM927D JCM933D/336D JCM946 |

|||

|

JCB JCB |

Upper arm, middle arm and lower arm |

JCB220 JCB240 JCB360 |

|||

Made of high quality materials, advanced production technology, with high durability.Using Japan NOK reflected the seal and the company unique sealing system design, can get the best sealing oil film and sealing performance. With advanced production equipment and technology, makes the piston rod, cylinder, cylinder head and piston and other main components has good surface roughness and super performance, etc

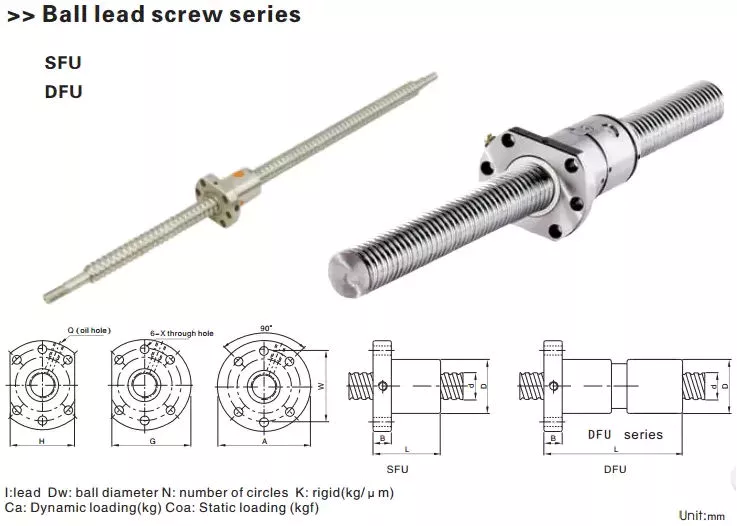

Specifying a Ball Screw

When you need a high-quality ball screw, it is important to select 1 with the proper dimensions and specifications. When you are looking for the best product, you should consider features such as preloading, surface finish, and internal return system. You can learn more about these features in this article. If you’re unsure which type of ball screw to select, contact a reputable supplier for further guidance. To find the best product for your needs, click here!

Brinelling

When specifying a Brinelling ball screw, it is crucial to know how much axial load it can safely bear. The static load capacity, which is given in the catalogue, applies only to pure axial loading, and any radial load that is smaller than 5% of the axial load won’t pose a problem. For more information, contact a CZPT engineer. Brinelling ball screw service life calculation should be performed using the following data:

Preload: The amount of load a ball screw can handle during a single revolution. Preload is the load applied before the ball screw starts moving, and the load is usually between 5 and 10 percent of the dynamic capacity. However, a ball screw that is subject to vibration will experience higher preload, requiring more frequent lubrication. The resulting mechanical stress may cause the ball screw to buckle, or cause the nut to re-circulate the balls.

Critical ball speed: The maximum speed at which the ball can move through the ball nut is called the critical ball speed. In contrast, running the ball screw at its critical shaft speed can lead to excessive vibrations, leading to premature failure of the end support bearings and brinelling of the ball track. Thus, it is recommended to operate a ball screw at a lower speed than the critical ball speed to prevent brinelling and plastic deformation of the balls.

False brinelling: False brinelling is a form of Fretting. False brinelling occurs when the bearings are not rotating. The movement will result in depressions or wear marks in the bearing raceway. This will cause noise, wear, and eventual fatigue. If these conditions persist, a newer ball screw should be used to test the system. The machine should be run for several hours and tested before replacing the bearing.

Preloading

The process of preloading ball screws minimizes backlash by applying pressure to the threads in the opposite direction of the screw’s direction of rotation. It prevents any movement of the screw relative to the nut. Various methods are used for preloading. A common 1 is to use oversized balls inside the ball nut. A double nut system may also be used. Both methods are equally effective. Regardless of the method used, the end result is the same – minimal backlash and increased efficiency.

In the conventional method of preloading ball screws, the motors operate simultaneously in opposite directions, causing them to have a relative motion of approximately equal magnitudes. This reduces the frictional resistance of the system, resulting in rapid traverse. The system is able to operate with minimal backlash during 110 inches of travel, reducing the heat developed by the drive nuts and the problems associated with ball screw heating. Moreover, this method can be used in a wide range of applications.

Another method of preloading ball screws is known as the ball-select method. This method includes the use of over-sized balls that force the balls into more contacts with the screw and nut than a normal ball screw. The advantage of this method is that it reduces backlash because the balls are not machined to high tolerances. The disadvantage of this method is that the ball screw will cost more to manufacture than a standard ball screw and nut.

A conventional design includes a mechanical mechanism that uses a series of balls to rotate a shaft. The problem of backlash is exacerbated by the mass of the shaft. The mechanical system is more complex than necessary and often requires a lot of effort. The present invention eliminates these problems by providing an improved method and apparatus for driving ball screws. This method provides a more efficient preload force that is dynamically adjustable while the mechanism is operating. The method can also improve friction and wear.

Internal return system

There are 2 different types of ball screws. The first type is external and the second is internal. The external type uses return tubes that protrude from the ball nut and extend above and around the outside of the screw. The internal type uses a single tube that spans the ball track, while the more common design uses multiple tubes spanning 1.5 to 3.5 ball tracks. The internal system involves a single return tube and several pickup fingers that guide the balls into the tubes.

The external return tube design is an easier, less expensive choice. The external ball return system has limited space but can handle a wide range of shaft diameters and leads. However, its physical size makes it incompatible with many high-speed applications. Therefore, careful consideration should be given to the mounting options. Internal ball return systems are best suited for small leads and ball sizes. Those that need a high speed will likely benefit from the external ball return system.

Internal ball screw technology has also kept pace with the demands of linear drive systems. Ball screw technology is now more durable than ever. Robust internal ball return systems circulate ball bearings through a solid pickup pin. These deflectors help the balls return to the screw in the correct location. They are crucial components in computer-controlled motion control systems and wire bonding. If you’re interested in the latest advances in linear screw technology, contact us today.

Ball screws are superior to lead screws in many ways. Ball screws are more efficient than lead screws, converting 90% of rotational motion into linear motion. As a result, they are more expensive than lead screws and acme screws. They also provide a smoother movement over the entire travel range. Furthermore, they require less power for the same performance. It’s no wonder that the ball screw is so popular in many different applications.

Surface finish

The surface finish of a ball screw is 1 of the key factors in determining the performance of the system. A ball screw with a good surface finish has superior performance in rolling resistance, backlash, and wear characteristics. However, it is critical to improve the surface finish of a ball screw to achieve precision movement, low wear, and low noise. To achieve this, special wire brushes will be used to polish precision-ground shafts.

For a ball screw to perform well, it must be hard, have a smooth surface, and retain lubricant. The surface finish of a ball screw should be smooth, free of cracks, and retain the lubricant well. Cracks and annealing are both undesirable during the manufacturing process, so a quality machine should be used for its surface finish. During the production process, a CBN cutting insert with full round or gothic arch profile can be used to achieve a high-quality surface finish.

Another finishing operation used in the manufacture of ball screws is lapping. Lapping improves surface quality and travel variation. It involves complex relative movements of abrasive particulates with the workpiece. This removes a thin layer of material from the workpiece, improving its surface quality and dimensional accuracy. The lapping process can be carried out under low-pressure conditions. It also enhances the friction torque and lubrication.

In lapping experiments, friction torque has the largest influence on travel variation and surface roughness. A friction torque of about 1 N x m is optimum. In addition, rotational speed has only a minimal effect. The best combination of these parameters is 1-1.5 N x m and 30 rpm. The minimum surface finish of a ball screw is around 800 mesh. The smallest variation in travel is observed at around half-way through the travel.

Lubrication

Proper lubrication of ball screw assemblies is critical to maintain optimum performance and life. Ball screw assemblies should be lubricated with grease, which is introduced directly into the ball nut. The lubrication port can be located at various locations on the product, including on the flange or in the external threads of the ball nut. Some ball nuts also feature a zerk fitting for easier lubrication.

The lubrication of ball screws is required in the case of operating conditions over 100oC. The minimum load for a ball screw is usually realized with a preload force. The lubricant is conveyed through the narrow lubrication gap due to the relative movement of the 2 surfaces. The increased viscosity of the lubricant enables separation of the contact surfaces. To avoid over-lubrication, it is important to check the lubricant level regularly.

The oil used in lubrication of ball screw assemblies can be either mineral or synthetic. The oil is composed of mineral or synthetic oil, additives, and a thickening agent, such as lithium or bentonite. Other thickening agents include lithium, barium complexes, or aluminum. The lubricant grade NLGI is a widely used classification for lubricating greases. It is not sufficient to choose a specific type of lubricant for a particular application, but it provides a qualitative measure.

Despite being essential to the performance of a ball screw, lubrication is also essential to its lifespan. Different types of lubricant offer corrosion protection. Before using a lubricant, make sure to thoroughly clean and dry the ball screw. If there is any buildup of dirt, it may damage the screw. To prevent this from occurring, you can use a solvent or lint-free cloth. Lubrication of ball screw assemblies can greatly extend the life of the assembly.