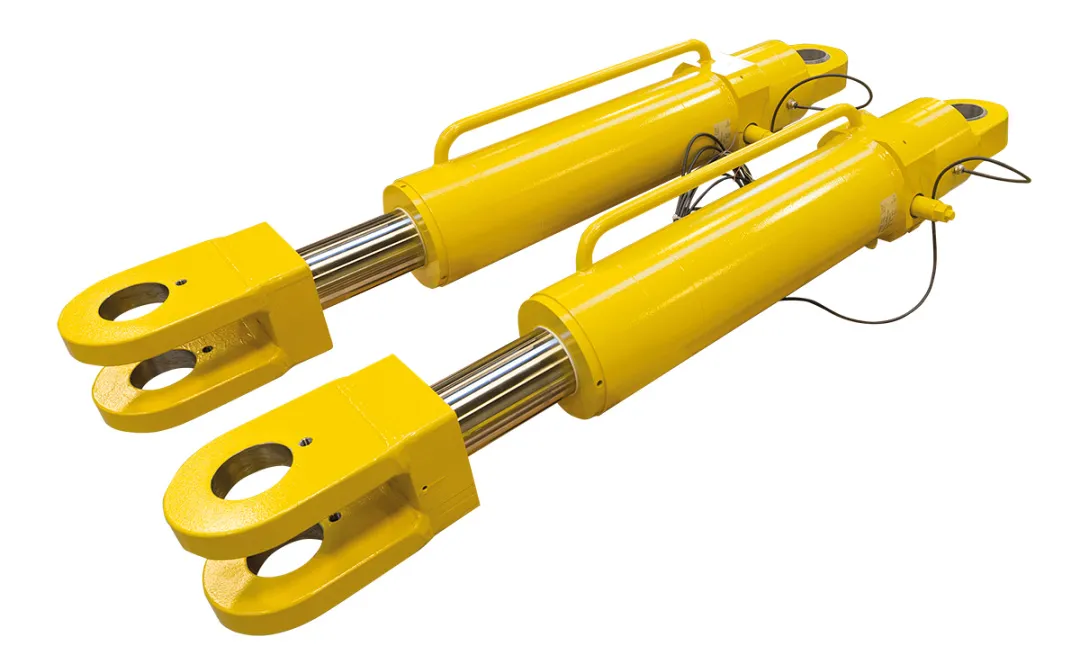

Welcome to the world of hydraulic power with the versatile Hydraulic Cylinder. This essential component plays a crucial role in various industries, enabling precise movement and force generation in hydraulic systems.

How To Measure Hydraulic Cylinder?

Bore Diameter:

Use a caliper or micrometer to measure the internal diameter of the cylinder bore. Ensure the measurement is taken at a few different points along the length to account for any potential variations.

Record the largest diameter measurement obtained.

Rod Diameter:

Measure the diameter of the rod using a caliper or micrometer. Take measurements at multiple points along the length to account for any tapering.

Record the smallest diameter measurement obtained.

Stroke Length:

Extend the cylinder to its maximum length and measure the distance from one end of the rod to the other. This measurement represents the stroke length.

Overall Length:

Measure from the base or mounting surface to the opposite end of the cylinder, accounting for any protruding components or fittings.

Products

Customers

Years

Key Features and Characteristics

Robust Construction

The Hydraulic Cylinder boasts a robust design, built to withstand high pressures and heavy loads. Constructed from durable materials, it ensures longevity and reliability, even in demanding environments. This cylinder is engineered to deliver consistent performance, making it a valuable asset in numerous applications. Learn More

Precision Control

With its exceptional precision, the Hydraulic Cylinder allows for accurate control of movement and force. Whether you need to lift, push, pull, or rotate, this cylinder provides smooth and precise operation, ensuring optimal performance and productivity. Learn More

Unlock Efficiency and Precision with the Hydraulic Cylinder

The Hydraulic Cylinder is meticulously engineered to provide precise control over movement and force. With its advanced design and high-quality construction, it ensures accurate and repeatable performance, allowing you to achieve the desired results with exceptional precision.

Unleash the Power of Durability with the Hydraulic Cylinder

When it comes to durability and longevity, the Hydraulic Cylinder stands out from the crowd. Crafted from top-quality materials and built to withstand the harshest conditions, this cylinder guarantees reliable performance even in the most demanding applications.

- Quality

- Precise

- Price

Hydraulic Cylinder For Sale

-

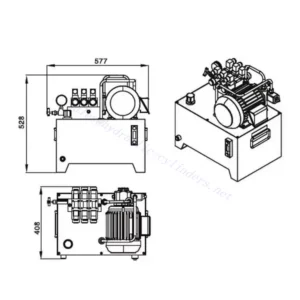

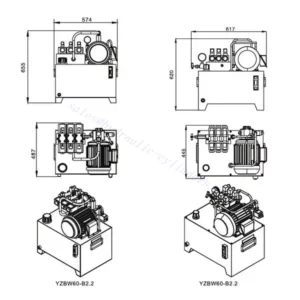

0.75KW With Cooling Fan Standard Hydraulic Power Unit Pack

-

0.75KW Without Cooling Fan Standard Hydraulic Power Unit Pack

-

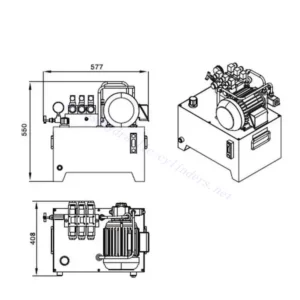

1.5KW With Cooling Fan Standard Hydraulic Power Unit Pack

-

1.5KW Without Cooling Fan Standard Hydraulic Power Unit Pack

-

2.2KW With Cooling Fan Standard Hydraulic Power Unit Pack

-

2.2KW Without Cooling Fan Standard Hydraulic Power Unit Pack

-

20176B-02000 Forklift Truck Support Hydraulic Cylinder

-

22/5142046 Steering Cylinder

-

25/5134221 Steering Cylinder

-

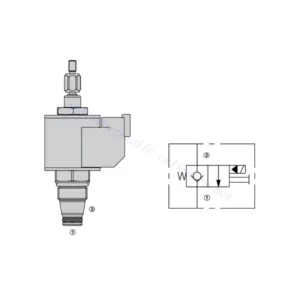

30SD08-20 Solenoid Directional Valve

-

30SD08-20J Solenoid Directional Valve

-

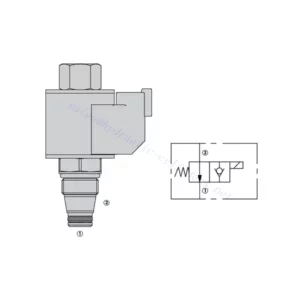

30SD08-21 Solenoid Directional Valve

If you want to buy hydraulic cylinder, we are your best choice, we also provide other types of hydraulic cylinders and the corresponding agricultural gearbox, if you need please contact us.

How To Rebuild A Hydraulic Cylinder?

Rebuilding a hydraulic cylinder can be a complex task that requires careful attention to detail and a good understanding of hydraulic systems.

Before starting any work, ensure that the hydraulic system is depressurized and the equipment is secure. Wear appropriate safety gear, such as gloves and eye protection, throughout the process.

- Remove the hydraulic cylinder from the equipment and place it on a clean, flat work surface.

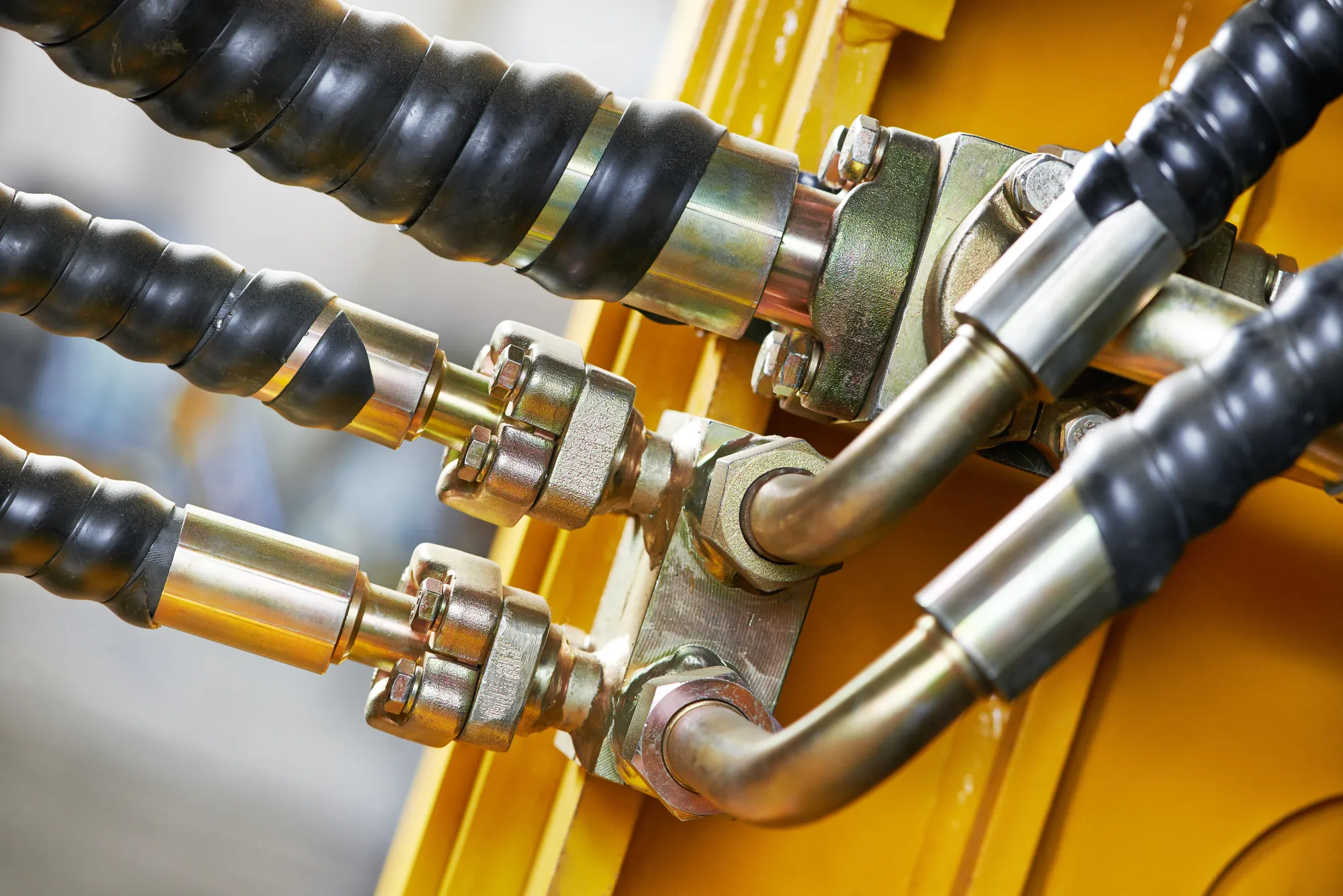

- Carefully remove any external components, such as mounting brackets, hoses, and fittings.

- Use a suitable tool, such as a wrench or socket, to loosen and remove the end caps of the cylinder. Take note of the order and position of any seals, bearings, or other internal components as you disassemble the cylinder.

- Thoroughly inspect all the components for signs of wear, damage, or corrosion. Pay close attention to the cylinder barrel, piston, rod, and seals.

- Measure the dimensions of critical components, such as the piston, rod, and cylinder bore, to ensure they are within the manufacturer’s specifications.

- Replace any damaged or worn-out parts, such as seals, bearings, or rods, with new ones. Ensure that the replacement parts are compatible with your specific hydraulic cylinder model.

- Clean all the disassembled components using an appropriate solvent to remove dirt, debris, and hydraulic fluid.

- Use a lint-free cloth or compressed air to dry the components thoroughly.

- Inspect the cylinder barrel for any scoring or pitting. If significant damage is found, it may need to be honed or replaced.

- Lubricate the seals, bearings, and other internal components with a compatible hydraulic fluid or assembly lubricant.

- Carefully reassemble the cylinder, following the reverse order of disassembly. Ensure that all components are correctly aligned and seated.

- Tighten the end caps to the manufacturer’s recommended torque specifications. Be cautious not to overtighten, as it may damage the seals or cause leaks.

- Before reinstalling the hydraulic cylinder, conduct a pressure test to ensure it functions properly. Apply a controlled pressure to verify that the cylinder extends and retracts smoothly without any leaks or abnormal noises.

- Once the hydraulic cylinder passes the pressure test, reinstall it into the equipment and reconnect any hoses, fittings, or mounting brackets.

- Finally, refill the hydraulic system with the appropriate hydraulic fluid and bleed any air from the system as necessary.

Recent News

How Mining Dump Truck Hydraulic Cylinder Repairing is Done

Mining dump trucks are the workhorses of the industry, hauling massive loads across rugged terrains. But when a Dump Truck Hydraulic Cylinder starts acting up, it can bring operations to a halt. Repairing these critical components, like the Dump Truck Cylinder or...

Working Principle of Garbage Truck Hydraulic Cylinder

Garbage truck hydraulic cylinder is an important part of transmission device of garbage truck, which is mainly used for connecting rod transmission between various parts of garbage truck and transferring power through hydraulic pressure to realize the top unloading...

Uses of Hydraulic Cylinders

Hydraulic cylinder is a core component that converts the pressure energy of liquid into mechanical energy, which is widely used in many industries. In modern machinery and equipment, it is widely used with high efficiency, high stability and strong adaptability. The...