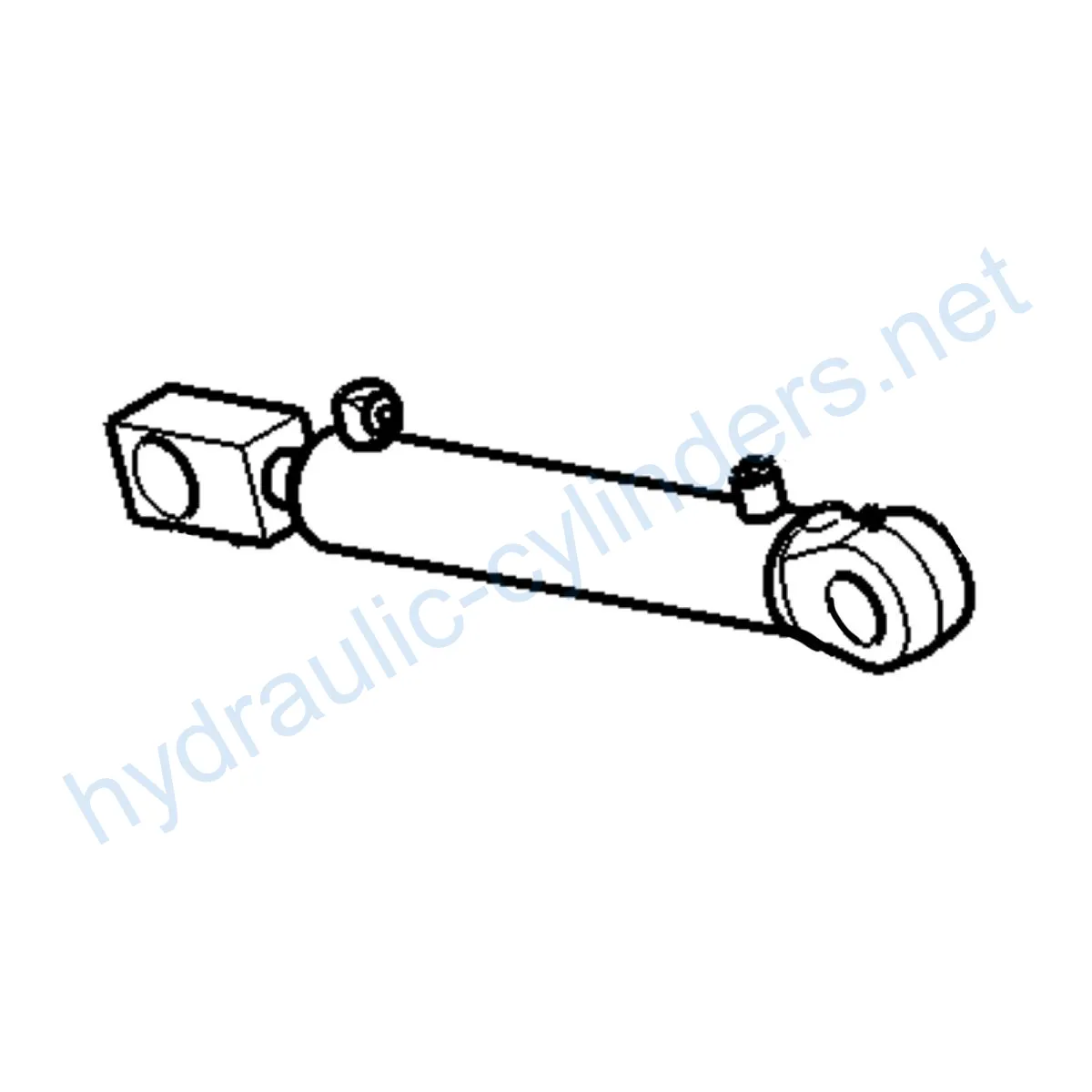

Replacement Of AHC19389 Hydraulic Cylinder

Като един от производителите, доставчиците и износителите на хидравлични цилиндри, ние предлагаме хидравлични цилиндри и много други продукти.

Моля, свържете се с нас за подробности.

Поща:sales@hydraulic-cylinders.net

Производител, доставчик и износител на хидравлични цилиндри.

Replacement Of AHC19389 Hydraulic Cylinder

The Replacement Of AHC19389 Hydraulic Cylinder is an important component of various heavy-duty equipment such as excavators, cranes, tractors, harvesters, and automated production lines. It serves as a mechanical actuator that converts hydraulic energy into mechanical force, providing the necessary power to move different parts of the equipment.

Specifications and Model

The Replacement Of AHC19389 Hydraulic Cylinder has a weight of 41.14 lb, a height of 4.2 in, a width of 6 in, and a length of 28 in. It is specifically designed to fit the 1870 P576 model, making it a reliable replacement for damaged or worn-out hydraulic cylinders of the same model.

Features

Improved Equipment Performance

Replacing damaged or worn-out hydraulic cylinders can restore the equipment’s normal operating ability, ensuring optimum performance in various applications.

Enhanced Safety

Regularly replacing hydraulic cylinders can reduce the safety hazards caused by cylinder failures, ensuring the safety of both the equipment and the operator.

Overload Protection

New cylinder designs usually consider better overload protection mechanisms, which improve safety.

Quick Installation

Modern hydraulic cylinders are designed to be easy to install and replace, reducing downtime.

Standardized Components

Many hydraulic cylinders are standardized products, making it easy to obtain replacement parts in the market.

Our company is capable of producing this product, and our Replacement Of AHC19389 Hydraulic Cylinder can perfectly replace these hydraulic cylinders.

Applications

Here are some examples of where the Replacement Of AHC19389 Hydraulic Cylinder can be used:

Excavators

The hydraulic cylinder found in the excavator arm or bucket may become damaged due to prolonged use or overload and needs to be replaced to restore normal operation.

Cranes

The hydraulic cylinder of the crane’s boom is susceptible to wear and tear during frequent lifting and lowering processes, so it needs to be replaced regularly to ensure safety.

Tractors

The hydraulic cylinder of the front-end loader of the tractor may leak or experience reduced performance due to continuous lifting and tilting operations, necessitating replacement.

Harvesters

During the harvesting process, the hydraulic system is subjected to high pressure, and the cylinder may become damaged due to fatigue, requiring timely replacement to maintain work efficiency.

Automated Production Lines

Hydraulic cylinders are used to control robotic arms and other automated equipment. If the cylinder fails, it can affect production efficiency, requiring immediate replacement.

Other Applications

Hydraulic cylinders are also used in mining equipment for lifting and moving heavy objects and in bulldozers for pushing and leveling operations.

Maintenance

Regular maintenance is crucial to ensure the longevity and performance of the Replacement Of AHC19389 Hydraulic Cylinder. Here are some common maintenance tasks:

Regular Inspection

Inspect the cylinder regularly for damage, leaks, and other issues, and replace any worn or damaged components as needed.

Proper Lubrication

Use the appropriate hydraulic oil and add it regularly to ensure proper lubrication and reduce wear and tear on the cylinder.

Seal Replacement and Calibration Check

Replace the seals as they wear out, and check the calibration to ensure that the cylinder operates properly.

During installation, it is essential to provide proper guidance for aligning the cylinder correctly. Using appropriate installation brackets to secure the cylinder is recommended. We also recommend following the recommended inspection, repair, and replacement procedures. We offer replacement parts and rebuilding services to extend the life of the hydraulic cylinder.

Safety and Environmental Considerations

It is essential to take safety measures when using the Replacement Of AHC19389 Hydraulic Cylinder. This includes following the recommended installation, maintenance, and safety procedures. Proper disposal of used hydraulic oil is also necessary to avoid environmental pollution.

Troubleshooting and Common Issues

Here are some common issues that may arise with the Replacement Of AHC19389 Hydraulic Cylinder:

Seal Leakage

The cylinder’s seals may leak due to wear and tear or improper installation.

Insufficient Force

The cylinder may not provide sufficient force due to a damaged piston or rod, insufficient hydraulic pressure, or improper installation.

Sticking or Binding

The cylinder may become stuck or bind due to debris in the hydraulic fluid, insufficient hydraulic pressure, or improper installation.

To troubleshoot these issues, it is essential to follow the recommended maintenance and inspection procedures. Proper diagnosis and replacement of damaged components are necessary to ensure the proper functioning of the hydraulic cylinder.

Design Considerations and Selection Criteria

The Replacement Of AHC19389 Hydraulic Cylinder is designed with several considerations in mind, including its load-bearing capacity, sealing properties, durability, safety, and maintainability.

Load-Bearing Capacity

The cylinder’s load-bearing capacity should match the requirements of the equipment it is being used for, taking into account factors such as weight, pressure, and frequency of use.

Sealing Properties

The cylinder’s seals should be made of durable materials such as polyurethane or nitrile rubber to withstand wear and tear. The cylinder’s body and threaded ends should be precisely machined to ensure a tight seal.

Durability

The cylinder’s body should be made of high-strength materials such as steel or aluminum alloys to withstand the heavy loads and pressure it will be subjected to during use.

Safety

The cylinder should be designed with safety features such as overload protection, proper alignment, and secure installation brackets to prevent accidents and equipment damage.

Maintainability

The cylinder should be designed for easy maintenance, with easy access to seals and other components, and clear guidelines for inspection and replacement.

Lubrication is crucial to ensure the proper functioning and longevity of the cylinder. Using various sealing components and lubricating with the appropriate hydraulic oil can help to extend the life of the cylinder. Regular inspection and maintenance, including seal replacement and calibration checks, are also essential to ensure the proper functioning of the hydraulic cylinder.

Our company is a leading manufacturer and wholesaler of hydraulic cylinders in the domestic and international markets, offering a wide range of products, customized services, and after-sales support. Our products meet international certifications, and our production equipment is state-of-the-art. We offer technical support, replacement parts, and rebuilding services to meet the needs of our customers.

Author: lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: