HM7X Series Axial Piston Fixed Displacement Hydraulic Motor

Jako jeden z výrobců, dodavatelů a vývozců hydraulických válců nabízíme hydraulické válce a mnoho dalších výrobků.

Kontaktujte nás, prosím, pro podrobnosti.

Mail:sales@hydraulic-cylinders.net

Výrobce, dodavatel a vývozce hydraulických válců.

HM7X Series Axial Piston Fixed Displacement Hydraulic Motor

The HM7X series axial piston fixed displacement hydraulic motor is a cutting-edge product designed to deliver exceptional power and efficiency in hydraulic systems. With its advanced features, durable construction, and precise control, this hydraulic motor sets new standards in the industry.

The HM7X series axial piston fixed displacement hydraulic motor is a powerful and efficient solution for hydraulic systems. Its robust design, high power density, and precise control offer exceptional performance, reliability, and longevity. By following the recommended usage methods and adhering to regular maintenance practices, the hm7x series motor will continue to deliver outstanding power and efficiency. Embrace the power and efficiency of the HM7X series axial piston fixed displacement hydraulic motor to unlock the full potential of your hydraulic system.

HM7X Series Axial Piston Fixed Displacement Hydraulic Motor Key Characteristics:

- Robust and Reliable Design: The HM7X series motor boasts a complete axial piston design, ensuring durability and reliability even in the most demanding applications. Crafted with high-quality materials and precision engineering, it can withstand high pressures and adverse operating conditions.

- High Power Density: Despite its compact size, the HM7X series motor offers an impressive power density, allowing it to deliver exceptional power output while occupying minimal space. This feature provides system design and installation flexibility, especially in applications with limited room.

- Efficient Power Transmission: The axial piston design of the HM7X series motor ensures efficient power transmission, minimizing energy losses and maximizing overall system efficiency. This results in reduced fuel consumption, lower operating costs, and a smaller carbon footprint, making it an environmentally friendly choice.

- Precise Control and Performance: The HM7X series motor offers precise control over speed and torque, allowing operators to tailor the motor’s output to match the application’s specific requirements. This accurate control leads to superior performance, smooth operation, and enhanced productivity.

HM7X Series Axial Piston Fixed Displacement Hydraulic Motor Parameter:

| Size | 45 | 63 | 75 | 85 | 100 | 130 |

| Max. Displacement cc/rev | 45 | 63 | 75 | 85 | 100 | 130 |

| Max. speed min-1 | 4000 | 5000 | 4500 | 4500 | 3550 | 3400 |

| Rated pressure bar | 280 | 400 | 400 | 400 | 400 | 400 |

| Max. pressure bar | 350 | 450 | 450 | 450 | 450 | 450 |

| Theoretical output torque Nm | 280 | 401 | 478 | 542 | 636 | 830 |

| Power Kw | / | 210 | 225 | 255 | 236 | 269 |

| Max. Flow L/min | 180 | 315 | 337 | 382 | 355 | 442 |

| Moment of inertia kg.m2 | 0.0036 | 0.0072 | 0.0072 | 0.011 | 0.015 | 0.025 |

| Volume in the case L | 0.7 | 1 | 1 | 0.5 | 0.5 | 1.2 |

| Mass Kg | 19.4 | 26 | 30.5 | 26 | 38 | 64.8 |

| Oil viscosity mm2/s | 5 ~ 1600,Best range:16~36 | / | ||||

| Temperature ℃ | at drain port: -20 ~ +115 at inlet port:-20 ~ +90 |

|||||

HM7X Series Axial Piston Fixed Displacement Hydraulic Motor Advantages:

HM7X45

• Swash plate type quantitative axial piston motor for open or closed type hydraulic drive circuit.

• Excellent high-speed performance.

• Plug-in design, compact installation space.

• High power to weight ratio.

• The bearing longevity is realized by the swash plate structure.

• The motor oil port is concentrated on one side for easy installation and oil circuit layout.

• Anti-reverse valve can be integrated

HM7X63/75/85/100/130/160

• High speed operation and smooth starting characteristics: Optimized rotary balance design high-speed performance and excellent starting characteristics.

• Low speed operation:Superior performance in low speed operation provides excellent controllability.

• Compact size:Swash plate conguration enables the motor to be much more compact.

• Long bearing life:Swash plate conguration results in longer bearing life.

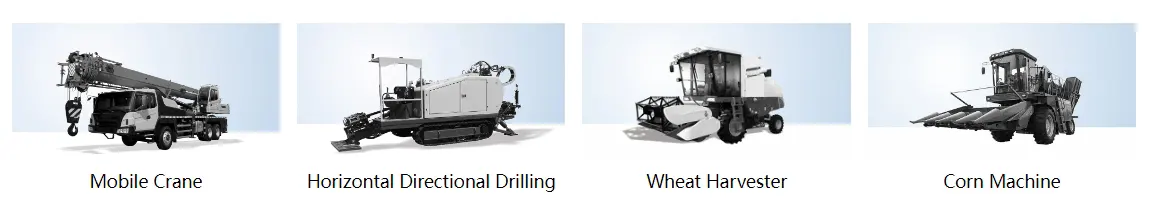

HM7X Series Axial Piston Fixed Displacement Hydraulic Motor Application:

Usage Method Of HM7X Series Axial Piston Fixed Displacement Hydraulic Motor:

- Mounting and Integration: Select a suitable location within your hydraulic system to mount the HM7X series axial piston fixed displacement hydraulic motor. Ensure proper alignment and securely mount the motor using appropriate brackets or accessories. Connect the motor to the hydraulic system using compatible fittings and hoses, ensuring tight and leak-free connections.

- Fluid Compatibility: Verify that the hydraulic fluid used in your system is compatible with the HM7X series motor. Refer to the manufacturer’s recommended fluid type, viscosity, and temperature range. Regularly monitor and maintain the hydraulic fluid to ensure optimal motor operation and longevity.

- Speed and Torque Control: Familiarize yourself with the speed and torque control options provided with the HM7X series motor. Depending on the specific model, it may offer various control methods, such as manual or proportional control. Understand the recommended control settings and adjust them accordingly to optimize motor performance.

- Load Considerations: Consider your application’s load requirements using the HM7X series motor. Ensure the motor’s power and torque ratings suit the intended task. Avoid overloading the engine to prevent excessive wear and potential damage.

How To Remove Hydraulic Clutch Line From Master Cylinder?

To remove the hydraulic clutch line from the master cylinder, follow these steps:

- Safety Precautions: Ensure the hydraulic system is depressurized before starting the disconnection process. This involves removing pressure from the system by releasing the clutch pedal several times or using a pressure-relief tool if available. Also, wear safety goggles and gloves to protect yourself from any potential fluid leakage.

- Locate the Master Cylinder: Identify the master cylinder, which is typically located on the engine compartment’s firewall. It is connected to the clutch pedal by a push rod and is easily identifiable by its fluid reservoir and hydraulic line connections.

- Access the Hydraulic Line: Depending on the vehicle’s make and model, you may need to remove other components or panels to gain access to the hydraulic line connected to the master cylinder. Use tools like wrenches or sockets to remove any necessary parts obstructing access.

- Position a Drain Pan: Place a drain pan or a suitable container beneath the hydraulic line connection point to catch any fluid that may drain out during the disconnection process.

- Loosen the Fittings: Locate the fittings that connect the hydraulic line to the master cylinder. These fittings are usually secured with retaining nuts or banjo bolts. Use an appropriate wrench or socket to loosen the fittings counterclockwise. Be cautious not to damage the fittings or the surrounding components.

- Remove the Line: Once the fittings are sufficiently loosened, carefully pull the hydraulic line away from the master cylinder. If the line feels stuck, gently wiggle it while applying a slight pulling force to release it from any residual pressure or corrosion.

- Cap the Openings: After removing the hydraulic line, quickly cap the master cylinder and the open end of the line with suitable caps or plugs to prevent dirt, debris, or fluid leakage. This step is crucial to maintain the cleanliness and integrity of the system during the line’s disconnection.

- Inspect and Replace: Take this opportunity to inspect the hydraulic line for any signs of damage, wear, or leaks. If necessary, replace the line with a new one to ensure proper functionality and prevent future issues.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: