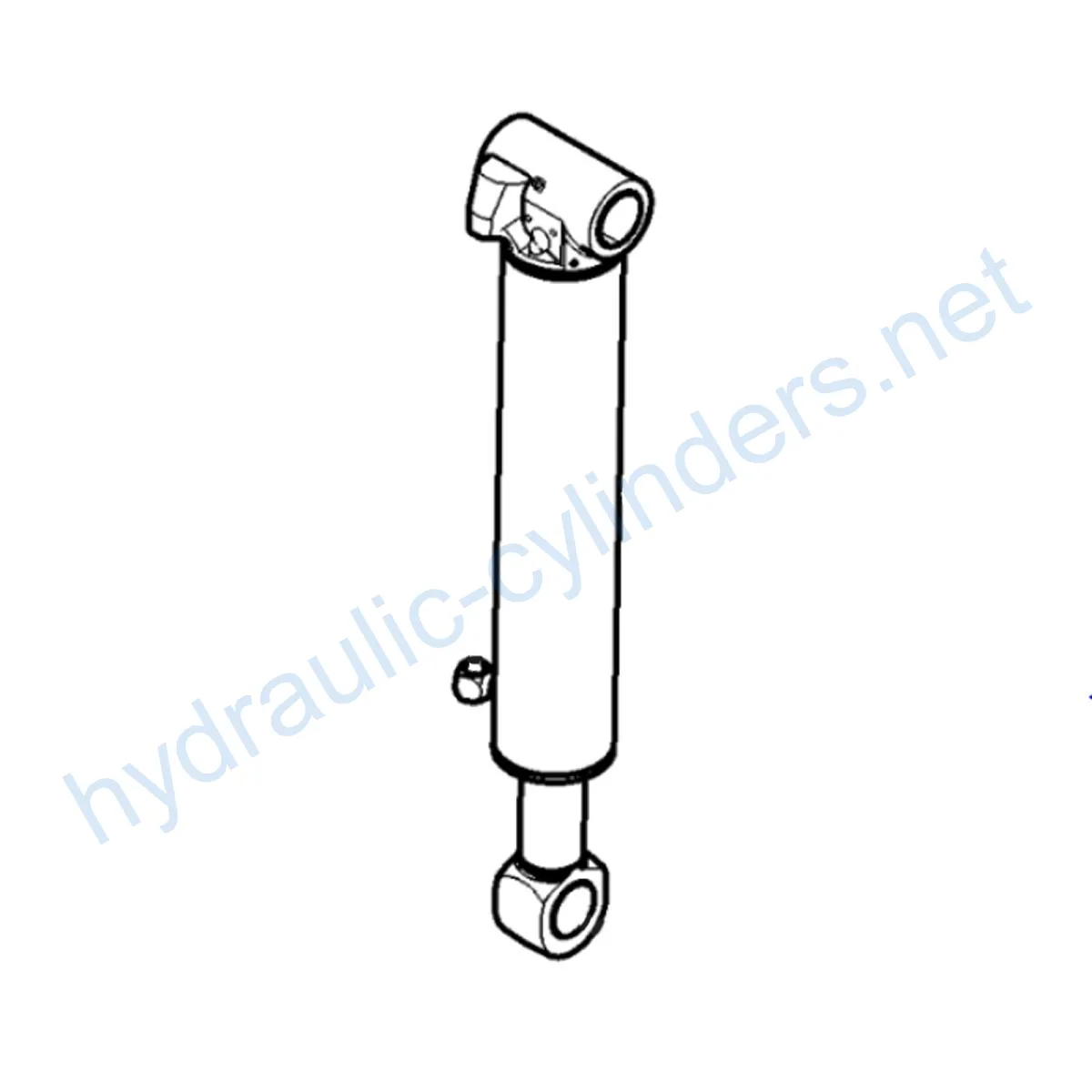

Replacement Of F702848 Hydraulic Cylinder

Jako jeden z výrobců, dodavatelů a vývozců hydraulických válců nabízíme hydraulické válce a mnoho dalších výrobků.

Kontaktujte nás, prosím, pro podrobnosti.

Mail:sales@hydraulic-cylinders.net

Výrobce, dodavatel a vývozce hydraulických válců.

Introduction

The Replacement Of F702848 Hydraulic Cylinder is an essential component of heavy-duty machinery. It is used to convert hydraulic energy into linear motion, which is critical in numerous industrial applications. The cylinder’s job is to lift, push or pull heavy equipment and objects. The product’s specifications include a weight of 223 lb, a height of 13.8 in, a width of 17.5 in, and a length of 50.5 in. The cylinder is compatible with the 1110G, 1210G, and 1510G models.

Specifications and Models

The cylinder’s weight, height, width, and length are 223 lb, 13.8 in, 17.5 in, and 50.5 in, respectively. It is compatible with the 1110G, 1210G, and 1510G models. These specifications make the cylinder ideal for heavy-duty machinery that requires a lift, push, or pull action.

Features

Improved Equipment Performance

Replacing damaged or worn-out hydraulic cylinders can restore equipment’s normal operating capabilities, ensuring its performance in various applications.

Enhanced Safety

Regularly replacing hydraulic cylinders can reduce safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

Overload Protection

New cylinder designs typically incorporate better overload protection mechanisms, enhancing safety.

Quick Installation

Modern hydraulic cylinder designs typically consider ease of installation and replacement, reducing downtime.

Standardized Parts

Many hydraulic cylinders are standardized products, making it easy to obtain replacement parts on the market.

Applications

Hydraulic cylinders are used in numerous applications in various industries. Some of these applications include:

- Excavators

- Cranes

- Tractors

- Harvesters

- Automated Production Lines

- Die Casting Machines

- Mining Equipment

- Bulldozers

These machines’ hydraulic cylinders are likely to become damaged or worn due to frequent use or overload, requiring replacement to restore normal operation.

Maintenance

Regular maintenance is necessary to ensure prolonged hydraulic cylinder life. The following are some common maintenance tasks:

- Periodic inspections

- Proper lubrication

- Seal replacement

- Calibration checks

Correct installation, lubrication, and adjustment are critical to ensure optimal performance. During installation, provide proper guidance on aligning the cylinder, use appropriate installation brackets to secure it, and recommend inspection, repair, and replacement procedures, as well as part replacement and rebuilding services to increase cylinder life.

Safety and Environmental Considerations

Safety measures are essential when using hydraulic cylinders. For instance, proper safety gear should be worn to protect operators from potential hazards. Environmental considerations such as reducing oil leaks and spills are crucial in maintaining a safe working environment.

Fault Diagnosis and Common Problems

Hydraulic cylinders are prone to various faults, including seal leaks, bent piston rods, and cylinder drift. To diagnose a fault, it is essential to inspect the cylinder for leaks, corrosion, or wear. Common problems include poor cylinder performance, faulty hydraulic systems, and environmental factors such as heat and dust.

Effective fault handling strategies include identifying the problem’s root cause, replacing faulty parts, and conducting preventative maintenance. To minimize potential issues, preventive measures such as regular inspections and proper lubrication are necessary.

Design Considerations and Selection Criteria

When selecting a hydraulic cylinder, several design and selection criteria come into play. The cylinder’s load-carrying capacity, sealing, durability, safety, and maintainability are crucial factors to consider.

Sealing and lubrication are primary factors that affect cylinder performance and longevity. Using high-quality materials such as polyurethane and nitrile rubber for seals can improve wear resistance. Cylinder bodies and threaded ends should be precisely machined to enhance wear resistance.

Installation Guide

Proper installation of hydraulic cylinders is vital in ensuring optimal performance. The following guidelines should be followed:

- Align the cylinder correctly

- Use appropriate mounting brackets for support

- Secure the cylinder firmly in place

Company Overview

We are a leading manufacturer and wholesaler of hydraulic cylinders, offering a broad range of products that meet domestic and international standards. Our company prides itself on offering customized services to suit each client’s specific needs. We have invested in modern production equipment and a reliable after-sales service team to ensure customer satisfaction.

Author: lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: