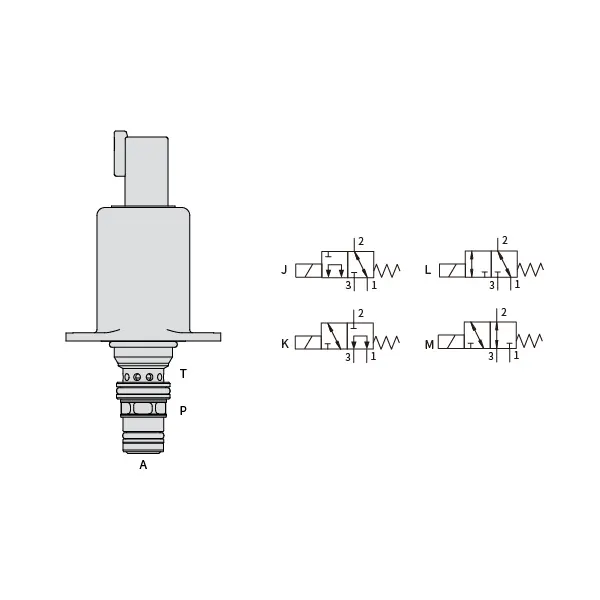

SDCV-05 Electromagnetic Directioanl Valve

Som en af producenterne, leverandørerne og eksportørerne af mekaniske produkter tilbyder vi hydrauliske cylindre og mange andre produkter.

Kontakt os for yderligere oplysninger.

Mail:sales@hydraulic-cylinders.net

Producent, leverandør og eksportør af hydrauliske cylindre.

SDCV-05 Electromagnetic Directioanl Valve

The sdcv-05 electromagnetic directional valve is an exceptional product engineered to provide precise control and efficient management of fluid flow in various industrial applications. With its advanced features and reliable performance, this valve offers unparalleled accuracy and responsiveness, making it an ideal choice for industries that require precise fluid control. From manufacturing to automation, the sdcv-05 electromagnetic directional valve ensures optimal performance and enhanced productivity.

The sdcv-05 electromagnetic directional valve offers precise fluid control capabilities, enabling optimal performance in various industrial applications. With its superior build quality, precision flow control, quick response time, and compact design, this valve provides reliability and efficiency in fluid management systems. By following the correct usage method and implementing regular maintenance practices, you can maximize the potential of the sdcv-05 electromagnetic directional valve, enhancing fluid control and productivity in your operations. Upgrade your fluid control system today with the precision and reliability of the sdcv-05 electromagnetic directional valve.

SDCV-05 Electromagnetic Directioanl Valve Characteristics:

- Superior Build Quality: Crafted with high-quality materials, the SDCV-05 Electromagnetic Directional Valve is designed to withstand demanding environments and deliver long-lasting performance. Its robust construction ensures durability, even in high-pressure applications, providing reliable fluid control in various conditions.

- Precision Flow Control: This valve offers exceptional precision in fluid management. With its precise adjustments, it enables accurate control over flow rates and direction, ensuring optimal system performance. This level of control allows for improved efficiency and reduced waste in fluid-dependent processes.

- Quick Response Time: The SDCV-05 Electromagnetic Directional Valve boasts a rapid response time, enabling swift and precise changes in fluid flow direction. This feature is particularly valuable in applications where immediate adjustments are required, enhancing overall system responsiveness and performance.

- Compact and Space-Saving Design: The valve’s compact size and space-saving design make it highly versatile and easy to integrate into existing fluid control systems. Its streamlined structure optimizes space utilization without compromising functionality, facilitating seamless installation in various setups.

SDCV-05 Electromagnetic Directioanl Valve Parameter:

| General | ||

| Weight | 0.203g | |

| Installation orientation | optional,recommend installing vertically with the connector plug down. | |

| MTTFd value | 150 year | |

| Ambient temperature range | -30~80℃ | |

| Hydraulic | ||

| Max.operating pressure | PP = 50bar | |

| Max. back pressure | PT = 30bar | |

| Degree of contamination | Maximum permissible degree of fluid contamination: Class 9. NAS 1638 or 20/18/15 , ISO4406 | |

| Fluid | Mineral oil (DIN 51524) | |

| Fluid temperature range | 30~105℃ | |

| Leakage | <100mL/min(power loss) | |

| <100mL/min(power on) | ||

| Filtration accuracy | 200μm(P 口) | |

| Electrical | ||

| Operating pressure(Ampilfier) | 12V | 24V |

| Coil resistance(20℃) | 9 Ω | 34 Ω |

| Connector form | DT04-2P Deutsch(Deutsch) | |

| Degree of protection | IP6K6/IPX9K | |

| Response Time | Commutation time<60ms | |

| Response Time<100ms | ||

SDCV-05 Electromagnetic Directioanl Valve Advantages:

• Quick response

• Compact size

• Wet type DC solenoid

Usage Method Of SDCV-05 Electromagnetic Directioanl Valve:

To effectively utilize the SDCV-05 Electromagnetic Directional Valve, follow these step-by-step instructions:

- Evaluate System Requirements: Assess the fluid control requirements of your system, including flow rates, pressure ratings, and directional control needs. Ensure that the SDCV-05 Electromagnetic Directional Valve is compatible with your specific application.

- Installation and Connection: Select an appropriate mounting method based on your system configuration and available space. Install the valve securely, aligning it with the fluid lines. Connect the valve using compatible fittings and connectors, ensuring tight and leak-free connections.

- Electrical Connection: Connect the electromagnetic coil of the valve to the appropriate power supply, following the manufacturer’s guidelines. Ensure correct wiring and observe safety precautions during the electrical connection process.

- Testing and Calibration: Gradually introduce fluid flow into the system and monitor the valve’s performance. Test different operating conditions, such as pressure and flow variations, and calibrate the valve settings as needed to achieve optimal control and system functionality.

How Does A Shower Valve Cartridge Work?

A shower valve cartridge is a key component of a shower valve system that controls the flow and temperature of water. It operates using a combination of mechanical and thermal elements to deliver the desired water temperature and regulate water flow. Here’s how a typical shower valve cartridge works:

- Flow Control: The shower valve cartridge controls the volume or flow rate of water. It consists of a mechanism that allows you to adjust the handle or lever, which, in turn, moves the cartridge within the valve body. As you turn the handle, the cartridge either opens or restricts the water flow, allowing you to achieve the desired water pressure.

- Temperature Control: The shower valve cartridge also manages the mixing of hot and cold water to control the water temperature. Inside the cartridge, there are two inlets for hot and cold water. By adjusting the handle, the cartridge moves a ceramic disc or other internal components that regulate the proportions of hot and cold water mixing together. This adjustment determines the water temperature that flows out of the showerhead.

- Thermal Sensing: Some shower valve cartridges utilize thermal sensing technology to maintain a consistent water temperature during a shower. These cartridges include a wax element or a thermostatic valve that reacts to changes in water temperature. If the incoming water becomes colder or hotter, the thermal element expands or contracts, adjusting the position of the internal components to compensate for the temperature change and maintain a steady water temperature.

- Diverter Functionality: In addition to flow and temperature control, certain shower valve cartridges feature a diverter function. The diverter allows you to redirect the water flow between different shower outlets, such as a showerhead, hand shower, or body jets. By activating the diverter handle or lever, the cartridge adjusts the internal flow paths to direct the water to the desired outlet.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: