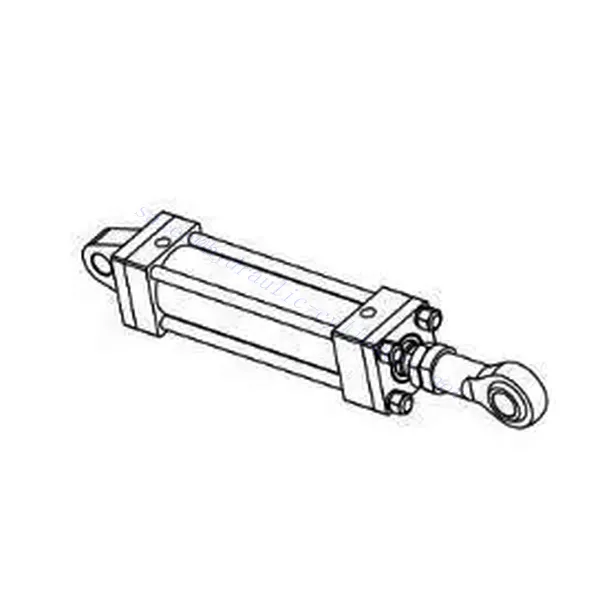

CA Monaural Typ Gksk Joint Ohrring Stecker Heavy Rod Hydraulic Cylinder

Als einer der Hersteller, Lieferanten und Exporteure von mechanischen Produkten, bieten wir Hydraulikzylinder und viele andere Produkte an.

Bitte setzen Sie sich mit uns in Verbindung, um Einzelheiten zu erfahren.

Post:sales@hydraulic-cylinders.net

Hersteller, Lieferant und Exporteur von Hydraulikzylindern.

CA Monaural Typ Gksk Joint Ohrring Stecker Heavy Rod Hydraulic Cylinder

The CA monaural type Gksk Articulated Earring Connector Heavy Rod hydraulic cylinder is a cutting-edge hydraulic element for heavy industrial applications. With its rugged construction, advanced features, and precise functionality, this hydraulic cylinder is designed to provide optimal power, reliability, and performance. Whether you need to lift, push or pull heavy loads, the CA Mono type Gksk Articulated Earring Connector heavy rod hydraulic cylinder can handle the most challenging tasks with ease.

Essential Characteristics Of Heavy Rod Hydraulic Cylinder:

Robust Construction: The CA monaural type Gksk hinged earring connector heavy rod hydraulic cylinder provides enhanced stability and motion control. The single rod extension ensures precise positioning and smooth operation, minimizing the risk of misalignment or deflection.

Monaural Type Design: The CA monaural type Gksk articulated earring connector heavy rod hydraulic cylinder provides enhanced stability and control of movement. The single rod extension ensures precise positioning and smooth operation, minimizing the risk of misalignment or deflection.

Gksk Joint Earring Connector: Equipped with a Gksk articulated earring connector, this hydraulic cylinder provides a convenient and safe connection to the hydraulic system. Connectors ensure reliable fluid transfer and minimize the risk of leakage or disconnection during operation, providing a worry-free experience.

Heavy Rod and High Force Output: The heavy rod design of this hydraulic cylinder, combined with its advanced hydraulic system, allows for exceptional force output. It can produce significant power, making it suitable for applications that require a lot of power and lifting capacity.

CA Monaural Type Gksk Joint Earring Connector Heavy Rod Hydraulic Cylinder Parameter:

CA Monaural Typ Gksk Joint Ohrring Stecker Heavy Rod Hydraulic Cylinder Usage Method:

Mounting: First, securely install the CA monaural Gksk articulated earring connector heavy rod hydraulic cylinder using the appropriate mounting brackets or fixtures. Ensure proper alignment and stability during installation to prevent cylinder misalignment or excessive stress.

Hydraulic System Integration: Follow the manufacturer’s instructions and guidelines to connect the hydraulic line to the Gksk knuckle earring connector of the cylinder. The cylinder is integrated into the hydraulic system by clicking it to a suitable pump or power unit. Ensure cylinder specifications and operating requirements are met.

Control and Operation: The control valve in the hydraulic system regulates the flow of hydraulic oil into and out of the cylinder. Adjust the control Settings to achieve the desired linear motion and force output. Test the movement of the cylinder to verify its function and responsiveness.

CA Monaural Typ Gksk Joint Ohrring Stecker Heavy Rod Hydraulic Cylinder Maintenance:

Regular maintenance is essential to ensure optimal performance and longevity of the CA Monaural Type Gksk Joint Earring Connector Heavy Rod Hydraulic Cylinder. Follow these maintenance guidelines:

Regular Inspection: Conduct routine inspections to identify signs of wear, damage, or leaks. Inspect the cylinder body, rod, seals, and other components for abnormalities. Address any issues promptly to prevent further injury or operational inefficiencies.

Lubrication: Apply the recommended lubricant to the moving parts of the cylinder, including tie rods and seals. Regular lubrication minimizes friction, reduces wear, and ensures smooth operation. Use the appropriate lubricant type according to the manufacturer’s lubrication interval guidelines.

Seal Replacement: If seals are found to be deteriorating or leaking, replace seals with genuine parts approved by the manufacturer. Damaged or worn seals can compromise the cylinder’s performance and lead to hydraulic oil leakage.

Cleaning: Clean cylinders by removing dirt, debris, and other contaminants. Before reassembling, use a non-abrasive cleaner and make sure all parts are arid. Regular cleaning promotes optimal performance and prevents premature wear or damage.

How Much Does It Cost To Rebuild A Hydraulic Cylinder?

The cost to rebuild a hydraulic cylinder can vary depending on several factors, including the size and type of the cylinder, the extent of the damage or wear, the availability of replacement parts, and the labor costs in your location. It’s important to note that rebuilding a hydraulic cylinder requires expertise and specialized tools, so it is often recommended to have the work done by a professional hydraulic repair service.

When considering the cost of rebuilding a hydraulic cylinder, you should take into account the following potential expenses:

- Labor Costs: The time and expertise required to disassemble, inspect, repair, and reassemble the cylinder will contribute to the overall cost. Labor rates can vary depending on the location and the specific repair service.

- Replacement Parts: If any components within the cylinder need to be replaced, such as seals, bearings, or rods, the cost of these parts will add to the total expense. The availability and price of replacement parts vary depending on the cylinder’s make and model.

- Machining or Honing: In some cases, the cylinder may require machining or honing to restore the surfaces to their proper specifications. This additional process can add to the overall cost of the rebuild.

- Testing and Certification: Once the cylinder has been rebuilt, it may need to undergo testing and certification to ensure its performance and safety. These additional services may come with associated costs.

Fähigkeit und Kapazität der Fabrik:

(1) Montage

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Bearbeitungen

Die Bearbeitungswerkstatt ist mit einem maßgeschneiderten Schrägschienen-Drehzentrum, einem Bearbeitungszentrum, einer Hochgeschwindigkeits-Honmaschine, einem Schweißroboter und anderen zugehörigen Geräten ausgestattet, die die Bearbeitung von Zylinderrohren mit einem maximalen Innendurchmesser von 400 mm und einer maximalen Länge von 6 Metern ermöglichen.

(3) Schweißen

(4) Malerei und Beschichtung

Mit kleinen und mittleren Zylinder automatische Lackieranlagen auf Wasserbasis, zu erreichen automatische Roboter Be-und Entladen und automatische Spritzen, die Design-Kapazität von 4000 Stück pro Schicht;

Wir verfügen auch über eine halbautomatische Lackieranlage für große Zylinder, die von einer Energiekette angetrieben wird und eine Kapazität von 60 Kisten pro Schicht hat.

(5) Prüfung

Wir verfügen über erstklassige Prüfeinrichtungen und Prüfstände, um sicherzustellen, dass die Leistung des Zylinders den Anforderungen entspricht.

We are one of the best heavy rod hydraulic cylinder manufacturers. We can offer wide heavy rod hydraulic cylinder stock. We also provide corresponding landwirtschaftliche Getriebe. Wir haben unsere Produkte an Kunden in der ganzen Welt exportiert und uns aufgrund unserer hervorragenden Produktqualität und unseres Kundendienstes einen guten Ruf erworben. Wir heißen Kunden im In- und Ausland herzlich willkommen, uns zu kontaktieren, um Geschäfte zu verhandeln, Informationen auszutauschen und mit uns zusammenarbeiten!

Machen Sie einen Rundgang durch unsere VR-Fabrik:

Machen Sie eine Tour durch unsere VR-Fabrik mit den folgenden

Wie funktioniert der Hydraulikzylinder für Gabelstapler?

Hydraulischer Zylinder Anwendung: