3KW With Cooling Fan Standard Hydraulic Power Unit Pack

Als einer der Hersteller, Lieferanten und Exporteure von mechanischen Produkten, bieten wir Hydraulikzylinder und viele andere Produkte an.

Bitte setzen Sie sich mit uns in Verbindung, um Einzelheiten zu erfahren.

Post:sales@hydraulic-cylinders.net

Hersteller, Lieferant und Exporteur von Hydraulikzylindern.

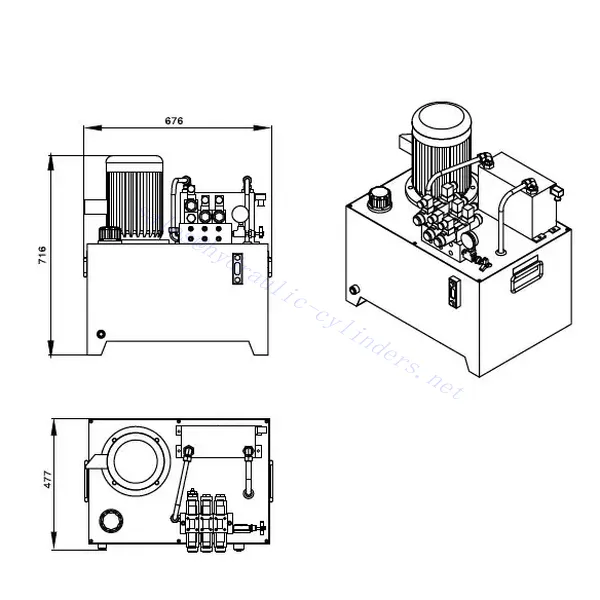

3KW With Cooling Fan Standard Hydraulic Power Unit Pack

The 3KW standard hydraulic power unit package with a cooling fan is a cutting-edge solution designed to deliver superior power and efficiency for a wide range of industrial applications. This hydraulic power unit offers a powerful 3KW motor, an integrated cooling fan, and a standard configuration that ensures optimal performance, reliable cooling, and ease of use. From machine tools to material handling equipment, the 3KW standard hydraulic power unit package with a cooling fan provides consistent power delivery, efficient cooling, and increased productivity.

Standard Hydraulic Power Unit Packs Model Description:

3KW With Cooling Fan Standard Hydraulic Power Unit Pack Parameter:

Standard Hydraulic Power Unit Packs Specification:

Standard Hydraulic Power Unit Packs Optional Parts:

Standard Hydraulic Power Unit Packs Schematic Diagram:

Standard Hydraulic Power Unit Packs Maintenance:

Regular Inspections:

- Perform routine inspections to identify any signs of leakage, damage, or wear in the 3KW cooling fan standard hydraulic power unit package.

- Inspect hydraulic hoses, fittings, and seals to ensure they function correctly and replace worn or damaged parts.

Cooling Fan Maintenance:

- Keep the cooling fan clean and debris-free to ensure the best heat dissipation effect.

- Check the fan blades regularly for damage or blockage, and clean them if necessary.

Fluid Level Check:

- Regularly monitor and maintain the hydraulic fluid level within the recommended operating range.

- Check hydraulic oil for signs of contamination or degradation and replace it if necessary.

Filter Maintenance:

- Clean or replace hydraulic filters as recommended by the manufacturer.

- Check the filter regularly for signs of blockage or damage that could affect the performance of the power unit.

How Does A One Way Hydraulic Cylinder Work?

A one-way, single-acting hydraulic cylinder uses a hydraulic system to generate linear motion in one direction. It consists of a cylinder barrel, piston, piston rod, and hydraulic fluid. Here’s how it works:

- Hydraulic Fluid Supply:

- The hydraulic system supplies pressurized fluid, typically oil, to the cylinder through a hydraulic pump or power source.

- Cylinder Extension:

- When hydraulic fluid is supplied to the cylinder, it enters the cylinder barrel through an inlet port.

- The pressurized fluid pushes against the piston, causing it to move in the desired direction (typically extending the piston rod).

- As the fluid pressure increases, it overcomes the resistance or load on the piston, resulting in the extension of the piston rod.

- Sealing Mechanism:

- The cylinder barrel is sealed to prevent fluid leakage. It typically incorporates seals around the piston and piston rod, such as O-rings or lip seals.

- These seals ensure that the pressurized fluid acts only on one side of the piston, creating a pressure imbalance that drives the piston in the desired direction.

- Return Stroke:

- After the extension stroke, the hydraulic fluid is released or vented from the cylinder.

- The hydraulic system may use gravity, a spring, or an external force to retract the piston and piston rod to their initial positions.

- During the return stroke, the hydraulic fluid flows out of the cylinder through an outlet port.

- Load Support:

- The piston rod of the hydraulic cylinder is often connected to a load or mechanism that requires linear motion or force.

- As the piston extends or retracts, it provides the necessary force to move or support the load.

- Control and Valves:

- To control the extension and retraction of the one-way hydraulic cylinder, the hydraulic system incorporates valves, such as check valves or directional control valves.

- These valves regulate the flow of hydraulic fluid, allowing it to enter and exit the cylinder in the desired direction.

- Application Specifics:

- One-way hydraulic cylinders are commonly used in applications where force or motion is required in only one direction, such as lifting, pushing, or clamping.

- They are often found in hydraulic jacks, hydraulic presses, dump trucks, and various other industrial and mobile equipment.

Fähigkeit und Kapazität der Fabrik:

(1) Montage

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Bearbeitungen

Die Bearbeitungswerkstatt ist mit einem maßgeschneiderten Schrägschienen-Drehzentrum, einem Bearbeitungszentrum, einer Hochgeschwindigkeits-Honmaschine, einem Schweißroboter und anderen zugehörigen Geräten ausgestattet, die die Bearbeitung von Zylinderrohren mit einem maximalen Innendurchmesser von 400 mm und einer maximalen Länge von 6 Metern ermöglichen.

(3) Schweißen

(4) Malerei und Beschichtung

Mit kleinen und mittleren Zylinder automatische Lackieranlagen auf Wasserbasis, zu erreichen automatische Roboter Be-und Entladen und automatische Spritzen, die Design-Kapazität von 4000 Stück pro Schicht;

Wir verfügen auch über eine halbautomatische Lackieranlage für große Zylinder, die von einer Energiekette angetrieben wird und eine Kapazität von 60 Kisten pro Schicht hat.

(5) Prüfung

Wir verfügen über erstklassige Prüfeinrichtungen und Prüfstände, um sicherzustellen, dass die Leistung des Zylinders den Anforderungen entspricht.

We are one of the best hydraulic power unit pack manufacturers. We can offer comprehensive hydraulic power unit pack stock. We also provide corresponding landwirtschaftliche Getriebe. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and mit uns zusammenarbeiten!

Machen Sie einen Rundgang durch unsere VR-Fabrik:

Machen Sie eine Tour durch unsere VR-Fabrik mit den folgenden

Hydraulischer Zylinder Anwendung: