HP5V Series Axial Piston Variable Displacement Hydraulic Pump

Als einer der Hersteller, Lieferanten und Exporteure von mechanischen Produkten, bieten wir Hydraulikzylinder und viele andere Produkte an.

Bitte setzen Sie sich mit uns in Verbindung, um Einzelheiten zu erfahren.

Post:sales@hydraulic-cylinders.net

Hersteller, Lieferant und Exporteur von Hydraulikzylindern.

HP5V Series Axial Piston Variable Displacement Hydraulic Pump

The HP5V series axial piston variable displacement hydraulic pump is a cutting-edge hydraulic component that offers unmatched efficiency and performance in various industrial applications. Designed with precision engineering and advanced technology, this pump delivers reliable and precise hydraulic power, making it an essential choice for demanding hydraulic systems. This comprehensive article will delve into the key characteristics, usage methods, and maintenance guidelines for the HP5V series axial piston variable displacement hydraulic pump.

The HP5V series axial piston variable displacement hydraulic pump is a high-performance and efficient solution for hydraulic systems. With its variable displacement technology, compact design, and quiet operation, this pump delivers reliable and precise hydraulic power. By following the recommended usage methods and adhering to regular maintenance practices, the HP5V series pump will continue to provide exceptional performance, contributing to the success of a wide range of industrial applications. Embrace the efficiency and performance of the hp5v series axial piston variable displacement hydraulic pump and unlock the full potential of your hydraulic system.

HP5V Series Axial Piston Variable Displacement Hydraulic Pump Key Characteristics:

- Variable Displacement Technology: The HP5V series pump features variable displacement technology, allowing it to adjust its output volume based on system requirements. This capability maximizes energy efficiency, reduces heat generation, and optimizes overall system performance.

- High Efficiency and Performance: The HP5V series pump delivers exceptional efficiency and performance with its advanced axial piston design. It provides precise and reliable hydraulic power, ensuring smooth operation and easy handling of high-pressure applications.

- Compact and Space-Saving Design: The pump’s compact design optimizes space utilization within hydraulic systems. Its small footprint allows easy integration, even in tight spaces, while maintaining excellent performance and functionality.

- Quiet Operation: The HP5V series pump is engineered with noise reduction features, ensuring quiet operation in diverse industrial environments. This characteristic is precious in applications that require low noise levels, promoting a comfortable and productive work environment.

HP5V Series Axial Piston Variable Displacement Hydraulic Pump Parameter:

| Size | HP5VS28 | HP5V28 | HP5V45 | HP5V60 | HP5V76 | HP5V85 | HP5V105 | |

| Displacement (cc/rev) | 28 | 28 | 45 | 60 | 76 | 85 | 104.3 | |

| Pressure | Rated pressure(bar) | 250 | 320 | 320 | 250 | 320 | 280 | 350 |

| Peak pressure(bar) | 315 | 350 | 350 | 280 | 350 | 320 | 400 | |

| Rotation speed r/min | Max for self-priming *1 (bar) | 3000 | 3000 | 2700 | 2400 | 2400 | 2400 | 2200 |

| Max*2 (bar) | 3600 | 3600 | 3250 | 3000 | 3000 | 3000 | 2600 | |

| Weight (Kg) | 17.2 | 20 | 24 | 24 | 28 | 28 | 45 | |

| Quantity of oil to fill pump case (L) | 0.55 | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 1 | |

| Temperature Range(℃) | -20~95 | |||||||

| Temperature Range(mm2/s) | 10-1000*3(The best use of viscosity range 16~36 mm2/s) | |||||||

HP5V Series Axial Piston Variable Displacement Hydraulic Pump Advantages:

• Variable pump in swash-plate design for open circuit.

• Compared with products in the existing market, reinforced drive shaft, high-strength cylinder material are utilized leading to the performance of continuous pressure of more than 320 bar.

• Heavy-duty bearings such as cylindrical rollers are adopted to enhance load carrying capacity and long service life.

• High power to weight ratio.

• Available with American (SAE) and Japanese (JIS) mounting flanges and shafts.

• Excellent reliability and long life.

• Variety of control options.

• Optional through drive.

• Quick control response.

• Low pressure pulsation and low noise.

• Developed for engineering, mobile vehicles,industrial, other industrial application and agricultural machinery.

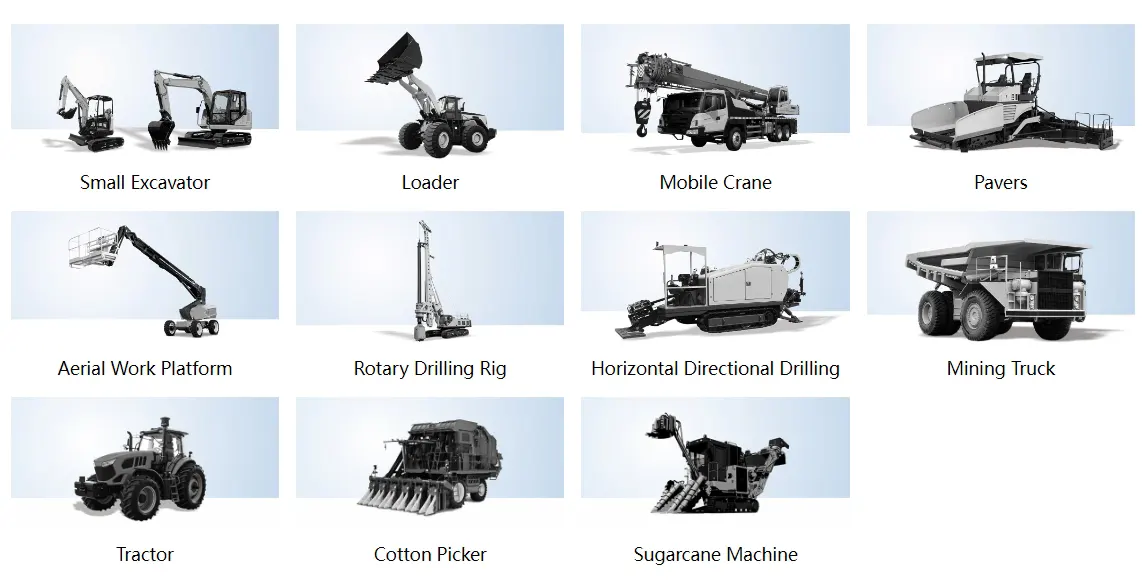

HP5V Series Axial Piston Variable Displacement Hydraulic Pump Application:

Verwendungsmethode von HP5V Series Axial Piston Variable Displacement Hydraulic Pump:

- Pump Installation: Install the HP5V series axial piston variable displacement hydraulic pump in the designated location within the hydraulic system. Refer to the manufacturer’s guidelines and specifications for proper alignment and secure attachment to the system’s structure using suitable mounting brackets or accessories.

- Hydraulic System Integration: Connect the pump to the hydraulic system using compatible hoses, fittings, and valves. Ensure all connections are secure, leak-free, and correctly tightened to guarantee optimal hydraulic performance.

- Fluid Compatibility: Verify that the hydraulic fluid used in the system is compatible with the HP5V series pump. Refer to the manufacturer’s recommendations for the appropriate fluid type, viscosity, and temperature range. Regularly monitor and maintain the hydraulic fluid to ensure proper pump operation and longevity.

- Operational Parameters: Familiarize yourself with the pump’s control options and adjust the operational parameters according to the specific requirements of the hydraulic system. Monitor and adjust the pump’s displacement settings to optimize performance and energy efficiency.

How To Change Seal On Hydraulic Cylinder?

Changing a seal on a hydraulic cylinder requires careful attention to detail and following proper procedures. Here’s a step-by-step guide to help you through the process:

- Preparation and Safety:

- Ensure the hydraulic cylinder is depressurized and disconnected from the system.

- Clean the exterior of the cylinder to prevent dirt or debris from entering during the process.

- Place the cylinder on a stable work surface and secure it using clamps or a vise.

- Identify the Seal:

- Determine the type of seal that needs replacement (e.g., rod seal, piston seal, wiper seal).

- Consult the cylinder’s technical documentation or contact the manufacturer to obtain the correct seal specifications.

- Disassembly:

- Remove any retaining components such as bolts, snap rings, or retaining rings that secure the cylinder head or cap.

- Carefully remove the cylinder head or cap, exposing the piston, rod, and the old seal.

- Remove the Old Seal:

- Use an appropriate tool like a seal pick, hook, or small screwdriver to pry out the old seal gently.

- Take care not to damage the cylinder surfaces during this process.

- Inspect the cylinder bore and rod for any signs of damage or wear. Consider a professional inspection or replacing the entire cylinder if significant damage is present.

- Clean and Lubricate:

- Thoroughly clean the cylinder bore, rod, and surrounding components using a lint-free cloth or a suitable solvent.

- Apply a thin layer of hydraulic oil or seal lubricant to the new seal to aid in installation and ensure proper sealing.

- Install the New Seal:

- Carefully position the new seal in its groove, ensuring it is correctly oriented.

- Use a seal installation tool or a soft mallet to gently press the seal into place, applying even pressure around its circumference.

- Ensure the seal is seated properly and fully inserted into the groove.

- Reassembly:

- Reinstall any remaining components removed during disassembly, such as bolts, snap rings, or retaining rings.

- Follow the manufacturer’s torque values and tightening sequence specifications to ensure proper sealing and alignment.

- Testing and Inspection:

- Reconnect the hydraulic cylinder to the system and ensure all connections are secure.

- Gradually restore system pressure and check for any leaks or abnormal behavior.

- Cycle the hydraulic cylinder through its full range of motion to verify proper seal operation.

Fähigkeit und Kapazität der Fabrik:

(1) Montage

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Bearbeitungen

Die Bearbeitungswerkstatt ist mit einem maßgeschneiderten Schrägschienen-Drehzentrum, einem Bearbeitungszentrum, einer Hochgeschwindigkeits-Honmaschine, einem Schweißroboter und anderen zugehörigen Geräten ausgestattet, die die Bearbeitung von Zylinderrohren mit einem maximalen Innendurchmesser von 400 mm und einer maximalen Länge von 6 Metern ermöglichen.

(3) Schweißen

(4) Malerei und Beschichtung

Mit kleinen und mittleren Zylinder automatische Lackieranlagen auf Wasserbasis, zu erreichen automatische Roboter Be-und Entladen und automatische Spritzen, die Design-Kapazität von 4000 Stück pro Schicht;

Wir verfügen auch über eine halbautomatische Lackieranlage für große Zylinder, die von einer Energiekette angetrieben wird und eine Kapazität von 60 Kisten pro Schicht hat.

(5) Prüfung

Wir verfügen über erstklassige Prüfeinrichtungen und Prüfstände, um sicherzustellen, dass die Leistung des Zylinders den Anforderungen entspricht.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding landwirtschaftliche Getriebe. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and mit uns zusammenarbeiten!

Machen Sie einen Rundgang durch unsere VR-Fabrik:

Machen Sie eine Tour durch unsere VR-Fabrik mit den folgenden

Hydraulischer Zylinder Anwendung: