HSG Series Hydraulic Cylinder Plant Protection Machinery

Als einer der Hersteller, Lieferanten und Exporteure von mechanischen Produkten, bieten wir Hydraulikzylinder und viele andere Produkte an.

Bitte setzen Sie sich mit uns in Verbindung, um Einzelheiten zu erfahren.

Post:sales@hydraulic-cylinders.net

Hersteller, Lieferant und Exporteur von Hydraulikzylindern.

HSG Series Hydraulic Cylinder Plant Protection Machinery

The HSG Series Hydraulic Cylinder is a vital component in plant protection machinery, designed to enhance the efficiency and effectiveness of agricultural operations. These hydraulic cylinders deliver robust performance, enabling precise control for various tasks such as spraying, fertilizing, and adjusting equipment height. Built for durability and reliability, the HSG Series ensures that farmers can maintain optimal plant health and yield.

The HSG Series Hydraulic Cylinder plays a crucial role in the efficiency and effectiveness of plant protection machinery. With their high load capacity, durable construction, and precision control, these cylinders empower operators to tackle a wide range of agricultural tasks efficiently. By following recommended usage and maintenance practices, users can ensure their hydraulic systems operate at peak efficiency, leading to successful farming outcomes. Investing in HSG Series Hydraulic Cylinders means prioritizing durability, efficiency, and precision in your agricultural operations.

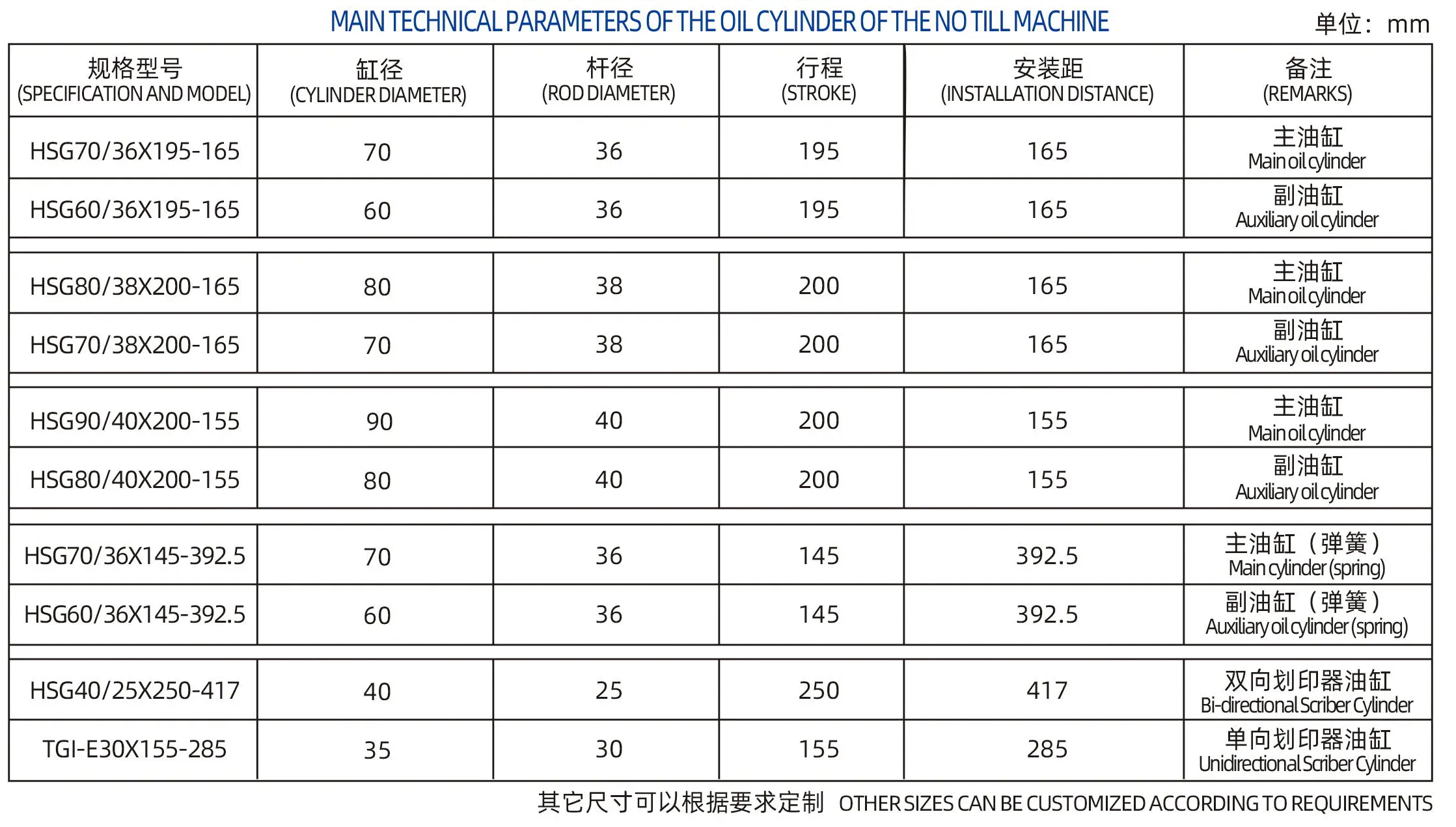

HSG Series Hydraulic Cylinder Plant Protection Machinery Parameters:

HSG Series Hydraulic Cylinder Plant Protection Machinery Key Features:

- Exceptional Load Handling: The HSG Series hydraulic cylinders are designed to manage heavy loads efficiently, providing the necessary strength to operate large attachments and equipment. This capability enhances the handling of materials, resulting in improved productivity and streamlined operations in the field.

- Robust and Reliable Construction: Constructed from premium-grade materials, these hydraulic cylinders are engineered to endure the rigors of harsh agricultural conditions. Their durable design minimizes wear and tear, ensuring long-lasting performance and reducing the need for frequent replacements, which translates to cost savings for farmers.

- Accurate Precision Control: Each hydraulic cylinder is manufactured with meticulous attention to detail, offering unparalleled precision in machinery operations. This level of accuracy allows operators to make fine adjustments during tasks such as pesticide spraying and fertilizer application, ensuring optimal coverage and effectiveness.

- Wide Compatibility with Equipment: The HSG Series hydraulic cylinders boast compatibility with a diverse range of plant protection machinery. This versatility enables seamless integration into existing setups, allowing farmers to easily upgrade their equipment without extensive modifications or additional investments.

- Innovative Leak Prevention Technology: Featuring advanced sealing technology, these hydraulic cylinders significantly minimize the risk of hydraulic fluid leaks. This innovation not only enhances operational efficiency but also reduces maintenance costs, enabling operators to concentrate on their tasks without the worry of unexpected downtime.

- Enhanced Performance in Extreme Conditions: Designed to perform reliably in extreme temperatures and challenging weather conditions, the HSG Series hydraulic cylinders maintain consistent functionality. This resilience ensures that agricultural operations can continue uninterrupted, regardless of environmental challenges.

- User-Friendly Design: The intuitive design of the HSG Series hydraulic cylinders simplifies installation and maintenance processes. Clear instructions and user-friendly features help operators quickly adapt to the equipment, enhancing overall user experience and productivity.

The HSG Series Hydraulic Cylinder stands out as a premier choice for plant protection machinery, combining exceptional load handling, durable construction, and precise control. With versatile compatibility and advanced leak prevention technology, these cylinders deliver reliable performance that meets the demands of modern agriculture. Investing in the HSG Series means choosing a solution that enhances efficiency, reduces maintenance costs, and ultimately contributes to successful farming operations.

HSG Series Hydraulic Cylinder Plant Protection Machinery Application:

HSG Series Hydraulic Cylinder Plant Protection Machinery Usage Method:

Using HSG Series Hydraulic Cylinders in plant protection machinery is a straightforward process that significantly enhances operational efficiency. Follow these detailed steps to ensure optimal performance:

1. Installation

Begin by securely mounting the hydraulic cylinders onto the machinery. Use the appropriate fittings and hardware to ensure a solid attachment. It’s crucial to double-check that all connections are tight to prevent hydraulic fluid leaks, which can severely impair performance. A well-executed installation not only safeguards against leaks but also ensures the stability and reliability of the hydraulic system during operation.

2. Connecting Hydraulic Lines

Next, attach the hydraulic lines to the cylinders. Pay careful attention to the flow direction as indicated in the user manual. Proper connections are essential for optimal hydraulic performance, as they facilitate efficient fluid movement throughout the system. Ensure that the lines are free of kinks or obstructions, which can hinder fluid flow and lead to performance issues. Taking the time to verify these connections will pay off in smoother operation.

3. Operation

Once the installation and connections are complete, operators can begin using the machinery. The hydraulic system allows for precise control over movements, enabling smooth adjustments whether lifting spray arms or tilting equipment for improved coverage. Familiarize yourself with the operational controls to maximize efficiency. The responsiveness of the HSG Series cylinders enhances maneuverability, making it easier to adapt to varying field conditions.

4. Monitoring Performance

Regular monitoring of the hydraulic system is vital for maintaining peak performance. Make it a habit to check hydraulic fluid levels and pressure gauges frequently. Keeping these within the manufacturer’s recommended parameters helps to identify potential issues early, preventing costly repairs and downtime. Additionally, monitoring ensures that the hydraulic system operates at its best, contributing to overall efficiency and reliability in your agricultural tasks.

5. Routine Maintenance

In addition to performance monitoring, implement a routine maintenance schedule. This should include regular inspections for signs of wear, damage, or leaks. Addressing these issues promptly can prevent more significant problems down the line. Keep the hydraulic fluid clean and replace it according to the manufacturer’s guidelines to ensure optimal performance and longevity.

By following these steps for installation, connecting hydraulic lines, operating, and monitoring performance, you can unlock the full potential of HSG Series Hydraulic Cylinders in plant protection machinery. This proactive approach not only enhances productivity but also ensures reliable operation, ultimately leading to successful agricultural outcomes. Embrace these practices to maximize the efficiency and durability of your hydraulic systems.

Test Equipment:

- 1: Salt Spray Test Chamber

- 2: Chemical Analysis

- 3: Tensile Testing Machine

- 4: Rockwell Hardness Tester

- 5: Cleanliness Testing Machine

- 6: TH110 Rebound Hardness Tester

- 7: Coating Thickness Gauge

- 8: Pendulum Impact Test

Our company considers quality to be the foundation of our success. To uphold this commitment, we have invested in cutting-edge domestic testing and laboratory equipment, supported by a team of highly skilled professionals in science and technology.

We maintain a rigorous quality management system that complies with industry standards, ensuring that every batch of products we produce meets the highest quality criteria. By standardizing our operations and continuously monitoring our processes, we ensure that our customers receive only the best.

This steadfast dedication to quality not only enhances the reliability of our products but also builds trust and satisfaction among our clients. We believe that by prioritizing excellence in every facet of our production, we contribute to the success of our partners and the industry as a whole. Together, we aim for innovation and quality that endure over time.

Hydraulic Cylinder Production Site:

Our company is a leading manufacturer specializing in hydraulic cylinders, backed by our own independent research, development, and design capabilities. With a state-of-the-art facility housing over 170 general machine tools, CNC machines, machining centers, welding equipment, and specialized testing and inspection tools, we are well-equipped to meet diverse industrial demands.

Through years of accumulated technological expertise and process refinement, we have established a mature production process that seamlessly integrates R&D with manufacturing. This integration has become our core competitive advantage, allowing us to design and produce a wide range of hydraulic cylinders customized to meet specific customer requirements.

Our products are widely used across various sectors, including agricultural machinery, construction equipment, vehicles, road engineering, and specialized machinery. We proudly support numerous OEMs, including Bonong Xingda, Bojin Hummer, Jilin Ruifeng, Debang Dawei, Shandong Yineng Heavy Industry, Tai’an Modern Heavy Industry, and Shifeng Group, among others.

We are dedicated to providing exceptional service through a strong quality policy that prioritizes continuous innovation in research and development, management, quality control, and customer service. Our commitment to quality has been recognized with ISO/TS16949 certification, which ensures that we not only meet but consistently exceed our clients’ expectations.

Looking ahead, we will continue to advance our technology and broaden our capabilities, always aiming to deliver the highest quality products and services to our customers. Together, we are forging a legacy of excellence in the hydraulic cylinder industry.

Machen Sie einen Rundgang durch unsere VR-Fabrik:

Machen Sie eine Tour durch unsere VR-Fabrik mit den folgenden

Hydraulischer Zylinder Anwendung: