Small Excavator Stick Cylinder

Als einer der Hersteller, Lieferanten und Exporteure von mechanischen Produkten, bieten wir Hydraulikzylinder und viele andere Produkte an.

Bitte setzen Sie sich mit uns in Verbindung, um Einzelheiten zu erfahren.

Post:sales@hydraulic-cylinders.net

Hersteller, Lieferant und Exporteur von Hydraulikzylindern.

Small Excavator Stick Cylinder

The Small Excavator Stick Cylinder is a highly reliable and robust hydraulic component designed to enhance the performance and efficiency of small excavators. This cylinder is specifically engineered to deliver exceptional power, precision, and durability in compact construction machinery.

The Small Excavator Stick Cylinder is a vital hydraulic component that significantly enhances the performance and efficiency of small excavators. With its compact design, impressive reach and digging depth, enhanced digging force, and precise control, this cylinder empowers operators to tackle excavation tasks easily and precisely. By following the recommended usage methods and maintenance practices, operators can ensure optimal performance and longevity of the Small Excavator Stick Cylinder, resulting in increased productivity and successful completion of construction and excavation projects. Invest in this exceptional hydraulic cylinder to elevate the capabilities of your small excavator and achieve superior results in your digging operations.

Small Excavator Stick Cylinder Key Characteristics:

- Compact Design and Sturdy Construction

- The Small Excavator Stick Cylinder is purpose-built for small excavators, ensuring a perfect fit and optimal performance.

- Its compact design and sturdy construction enable it to withstand demanding operating conditions, providing long-lasting durability.

- Impressive Reach and Digging Depth

- Despite its small size, the cylinder offers impressive reach and digging depth capability, maximizing the excavator’s operational range.

- It allows operators to access confined spaces and effectively excavate in tight areas precisely and easily.

- Enhanced Digging Force and Efficiency

- The cylinder delivers enhanced digging force, enabling efficient excavation of various materials, including soil, rocks, and debris.

- It optimizes the excavator’s digging performance, increasing productivity and reducing project completion time.

- Smooth Operation and Precise Control

- The Small Excavator Stick Cylinder incorporates advanced hydraulic technologies for smooth operation and precise control.

- It offers excellent responsiveness, allowing operators to perform delicate operations with accuracy and efficiency.

Small Excavator Stick Cylinder Parameter:

| Product Name | Small Excavator Stick Cylinder |

| Features: | Control the movement of the forearm |

| Bore diameter: | 50mm~115mm |

| Rod diameter: | 25mm~70mm Stroke≤1000mm |

| Thrust force: | Maximum 305KN |

| Bore diameter: | 115mm/pressure29.4MPa) |

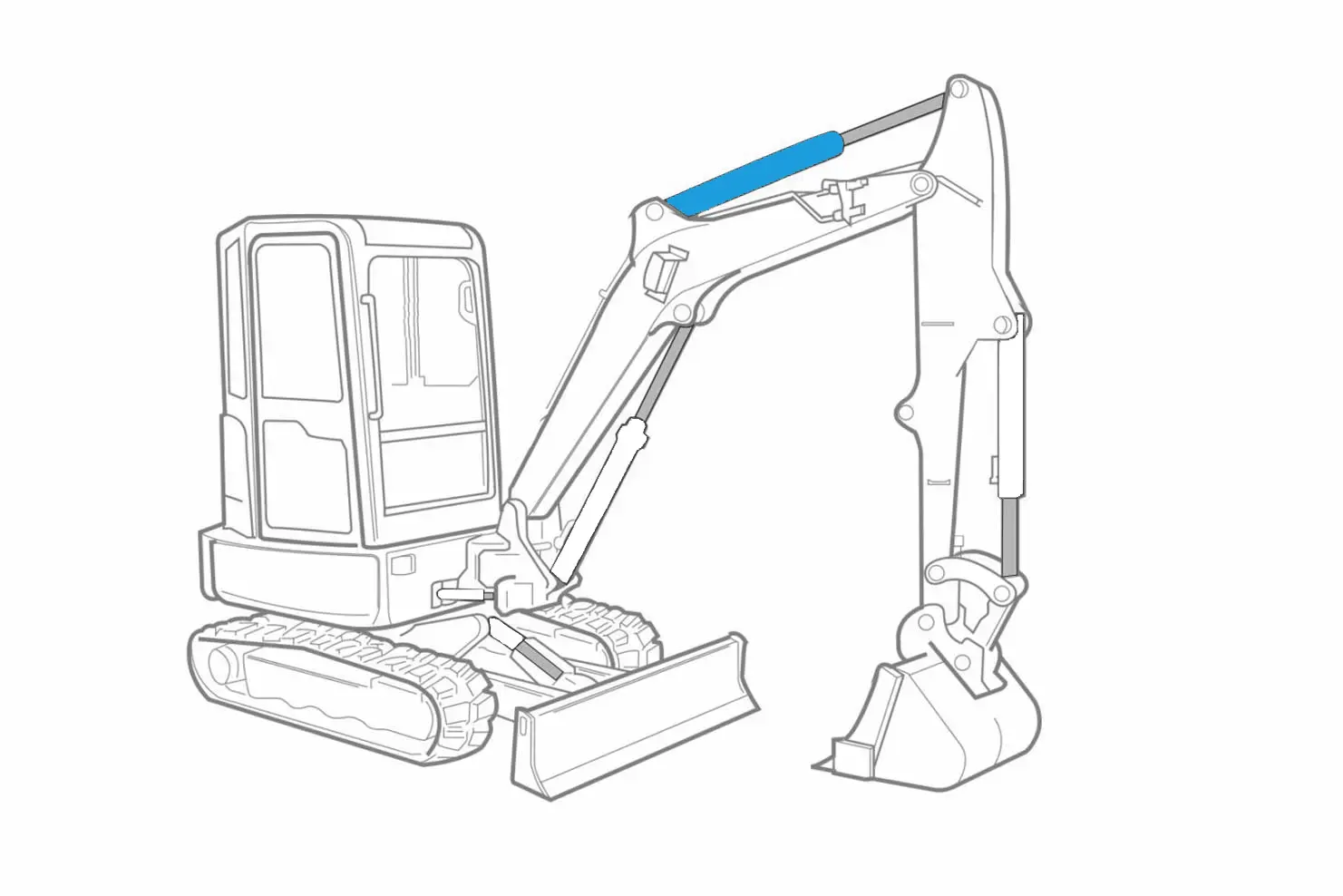

Small Excavator Stick Cylinder Identification Diagram:

Usage Method Of Small Excavator Stick Cylinder:

- Installation and Integration

- Refer to the manufacturer’s instructions for proper installation of the Small Excavator Stick Cylinder.

- Ensure compatibility and securely attach the cylinder to the excavator’s stick assembly.

- Follow recommended torque specifications and use appropriate mounting hardware.

- Operational Considerations

- Familiarize yourself with the controls and operation of the excavator, including the stick cylinder.

- Practice operating the excavator and stick cylinder in a controlled environment before commencing actual work.

- Adhere to safety guidelines and operate within the excavator’s load and reach limits to prevent accidents and equipment damage.

- Optimizing Digging Performance

- Utilize the Small Excavator Stick Cylinder’s precise control to optimize digging performance.

- Maintain a stable position while digging, avoiding sudden or jerky movements that can strain the cylinder.

- Ensure proper bucket positioning and tooth engagement for efficient excavation.

What Size Cylinder For Excavator Thumb?

The size of the cylinder for an excavator’s thumb can vary depending on the specific requirements of the excavator and the intended use of the thumb attachment. The appropriate size of the cylinder is typically determined by considering factors such as the excavator’s operating weight, the desired lifting capacity of the thumb, and compatibility with the excavator’s hydraulic system.

To determine the suitable cylinder size for an excavator thumb, it is recommended to consult the manufacturer or supplier of the thumb attachment. They can provide guidance based on the excavator’s specifications and the thumb’s intended application.

It’s worth noting that excavator thumbs are available in various sizes and configurations to accommodate different excavator models and sizes. The thumb attachment typically consists of a central structure or frame that mounts to the excavator’s boom and a hydraulic cylinder that provides the gripping or clamping action. The cylinder size should be selected to ensure compatibility with the thumb attachment and to provide the required gripping force for the intended tasks.

When considering the cylinder size for an excavator’s thumb, it’s essential to strike a balance between having sufficient lifting capacity and ensuring that the excavator’s hydraulic system can adequately support the operation of the thumb. Oversizing the cylinder may strain the excavator’s hydraulic system excessively, while under sizing, may result in limited lifting capacity and reduced performance.

In summary, the size of the cylinder for an excavator thumb should be determined based on factors such as the excavator’s operating weight, desired lifting capacity, and compatibility with the thumb attachment and hydraulic system. Consulting the manufacturer or supplier of the thumb attachment is recommended to ensure proper sizing and optimal performance.

Fähigkeit und Kapazität der Fabrik:

(1) Montage

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Bearbeitungen

Die Bearbeitungswerkstatt ist mit einem maßgeschneiderten Schrägschienen-Drehzentrum, einem Bearbeitungszentrum, einer Hochgeschwindigkeits-Honmaschine, einem Schweißroboter und anderen zugehörigen Geräten ausgestattet, die die Bearbeitung von Zylinderrohren mit einem maximalen Innendurchmesser von 400 mm und einer maximalen Länge von 6 Metern ermöglichen.

(3) Schweißen

(4) Malerei und Beschichtung

Mit kleinen und mittleren Zylinder automatische Lackieranlagen auf Wasserbasis, zu erreichen automatische Roboter Be-und Entladen und automatische Spritzen, die Design-Kapazität von 4000 Stück pro Schicht;

Wir verfügen auch über eine halbautomatische Lackieranlage für große Zylinder, die von einer Energiekette angetrieben wird und eine Kapazität von 60 Kisten pro Schicht hat.

(5) Prüfung

Wir verfügen über erstklassige Prüfeinrichtungen und Prüfstände, um sicherzustellen, dass die Leistung des Zylinders den Anforderungen entspricht.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding landwirtschaftliche Getriebe. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and mit uns zusammenarbeiten!

Machen Sie einen Rundgang durch unsere VR-Fabrik:

Machen Sie eine Tour durch unsere VR-Fabrik mit den folgenden

Hydraulischer Zylinder Anwendung: