V30D Series Axial Piston Variable Displacement Hydraulic Pump

Als einer der Hersteller, Lieferanten und Exporteure von mechanischen Produkten, bieten wir Hydraulikzylinder und viele andere Produkte an.

Bitte setzen Sie sich mit uns in Verbindung, um Einzelheiten zu erfahren.

Post:sales@hydraulic-cylinders.net

Hersteller, Lieferant und Exporteur von Hydraulikzylindern.

V30D Series Axial Piston Variable Displacement Hydraulic Pump

The V30D series axial piston variable displacement hydraulic pump is a state-of-the-art solution designed to deliver exceptional performance and efficiency in various hydraulic applications. With its advanced engineering, versatile design, and precise control, this hydraulic pump is a game-changer in the industry.

The V30D series axial piston variable displacement hydraulic pump sets a new standard for efficiency and performance in hydraulic systems. With its variable displacement technology, high performance, and versatile design, this pump offers superior control and optimized energy utilization. By following the recommended usage methods and adhering to regular maintenance practices, the V30D series pump will continue to deliver exceptional efficiency and power, contributing to the success of various industrial applications. Harness the power and efficiency of the V30D series axial piston variable displacement hydraulic pump to elevate the performance of your hydraulic system.

V30D Series Axial Piston Variable Displacement Hydraulic PumpKey Characteristics:

- Variable Displacement Technology: The V30D series pump incorporates cutting-edge variable displacement technology, allowing it to adjust the pump’s output based on the system’s demand. This feature ensures optimal energy utilization, resulting in increased efficiency and reduced power consumption.

- High Performance: This hydraulic pump sets new benchmarks in terms of performance. With a wide range of operating pressures and speeds, the V30D Series Pump provides precise control and efficient power delivery, enabling superior system performance and productivity.

- Versatile Design: The V30D series pump is designed to accommodate various hydraulic systems and applications. It offers flexibility in mounting options, fluid compatibility, and control methods, making it suitable for a wide range of industries and machinery.

- Efficiency at Any Load: The V30D series pump ensures efficiency across a wide range of loads thanks to its variable displacement feature. It automatically adjusts the output to match the system’s requirements, minimizing energy losses and maximizing productivity.

V30D Series Axial Piston Variable Displacement Hydraulic Pump Parameter:

| Size | Displacement cc/rev | Pressure bar | Rotation speed r/min | ||

| Rated | Peak | Max for self-priming*1 | Max*2 | ||

| V30D45 | 45 | 350 | 420 | 2600 | 3600 |

| V30D75 | 75 | 350 | 420 | 2400 | 3200 |

| V30D95 | 96 | 350 | 420 | 2200 | 2900 |

| V30D115 | 115 | 250 | 300 | 2000 | 2800 |

| V30D140 | 142 | 350 | 420 | 2200 | 2600 |

| V30D160 | 164 | 250 | 300 | 1900 | 2500 |

| V30D250 | 250 | 350 | 420 | 1800 | 2000 |

| V30D520 | 520 | 400 | 450 | 1500 | 1800 |

V30D Series Axial Piston Variable Displacement Hydraulic Pump Advantages:

• Applied in open circuit hydraulic systems

• Low noise

• Multiple control modules

• Provides sufficient torque for the rear pump when a tandem pump application is required

V30D Series Axial Piston Variable Displacement Hydraulic Pump Application:

Usage Method Of V30D Series Axial Piston Variable Displacement Hydraulic Pump:

- Installation and Integration: Choose an appropriate location within the hydraulic system to install the V30D series axial piston variable displacement hydraulic pump. Ensure proper alignment and securely mount the pump using suitable brackets or accessories. Connect the pump to the hydraulic system using compatible fittings and hoses, ensuring leak-free connections.

- Fluid Compatibility: Verify that the hydraulic fluid used in the system is compatible with the V30D series pump. Refer to the manufacturer’s recommended fluid type, viscosity, and temperature range. Regularly monitor and maintain the hydraulic fluid to ensure optimal pump operation and longevity.

- Control and Adjustment: Familiarize yourself with the control options provided with the V30D series pump. Depending on the specific model, it may offer various control methods such as manual, proportional, or electronic control. Understand the recommended control settings and adjust them accordingly to optimize pump performance.

- System Optimization: The V30D series pump allows system optimization by adjusting the pump’s displacement to match the load requirements. Take advantage of this feature to maximize energy efficiency and overall system performance.

How To Bleed A Hydraulic Cylinder Without Bleeder Valve?

Bleeding a hydraulic cylinder without a bleeder valve can be a bit more challenging, but it is still possible. Here’s a step-by-step guide on how to bleed a hydraulic cylinder without a bleeder valve:

- Safety First: Before working on the hydraulic cylinder, ensure that the system is depressurized. Please turn off the power supply and relieve any residual pressure by activating the pressure release valve or operating the system to its maximum extension or retraction point.

- Position the Cylinder: Place the hydraulic cylinder in a position where air bubbles can easily rise to the highest point. This typically means having the cylinder vertically with the rod pointing upward.

- Remove the Fitting: Locate the fitting that connects the hydraulic line to the cylinder. Use appropriate tools to disconnect the fitting and remove it. Be prepared for some hydraulic fluid to leak out during this process, so have a container or rags ready to catch any spills.

- Raise the Cylinder: If possible, raise the cylinder to its maximum extension position. This helps minimize the amount of air trapped inside the cylinder.

- Tap the Cylinder: Lightly tap the sides of the cylinder with a rubber mallet or a soft-faced hammer. This helps dislodge any air bubbles that may be trapped inside the cylinder. Start from the bottom and work your way up, tapping around the cylinder’s circumference.

- Cycle the Cylinder: Operate the hydraulic system to cycle the cylinder a few times. Extend and retract the cylinder fully, allowing the hydraulic fluid to flow through and potentially push out any air bubbles. Repeat this process several times to ensure thorough bleeding.

- Reconnect the Fitting: Once you have cycled the cylinder and feel that most of the air has been purged, reconnect the fitting to the hydraulic line. Ensure it is tightened securely but not overtightened, as it may damage the fitting or cause leaks.

- Test the Cylinder: After bleeding the cylinder, test its operation by extending and retracting it fully. Monitor the cylinder for any signs of air bubbles or abnormal behavior. If you notice any issues, repeat the bleeding process or seek assistance from a hydraulic professional.

Fähigkeit und Kapazität der Fabrik:

(1) Montage

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Bearbeitungen

Die Bearbeitungswerkstatt ist mit einem maßgeschneiderten Schrägschienen-Drehzentrum, einem Bearbeitungszentrum, einer Hochgeschwindigkeits-Honmaschine, einem Schweißroboter und anderen zugehörigen Geräten ausgestattet, die die Bearbeitung von Zylinderrohren mit einem maximalen Innendurchmesser von 400 mm und einer maximalen Länge von 6 Metern ermöglichen.

(3) Schweißen

(4) Malerei und Beschichtung

Mit kleinen und mittleren Zylinder automatische Lackieranlagen auf Wasserbasis, zu erreichen automatische Roboter Be-und Entladen und automatische Spritzen, die Design-Kapazität von 4000 Stück pro Schicht;

Wir verfügen auch über eine halbautomatische Lackieranlage für große Zylinder, die von einer Energiekette angetrieben wird und eine Kapazität von 60 Kisten pro Schicht hat.

(5) Prüfung

Wir verfügen über erstklassige Prüfeinrichtungen und Prüfstände, um sicherzustellen, dass die Leistung des Zylinders den Anforderungen entspricht.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding landwirtschaftliche Getriebe. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and mit uns zusammenarbeiten!

Machen Sie einen Rundgang durch unsere VR-Fabrik:

Machen Sie eine Tour durch unsere VR-Fabrik mit den folgenden

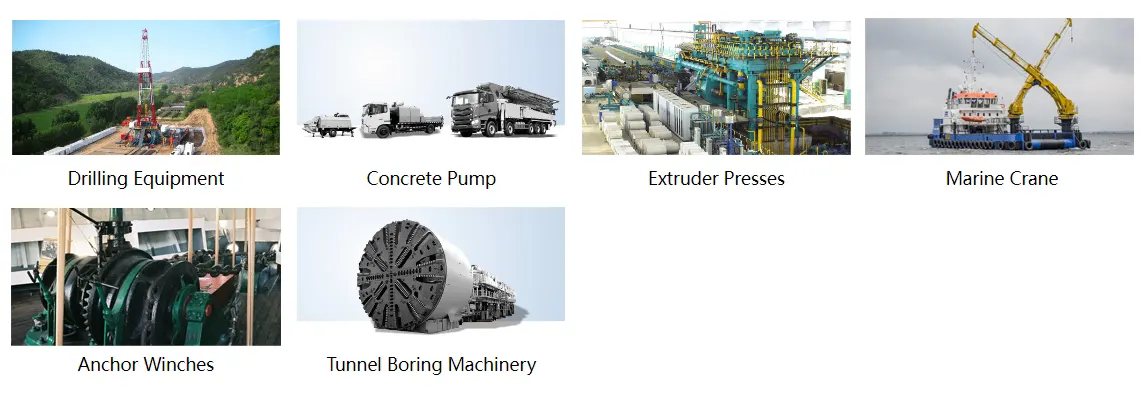

Hydraulischer Zylinder Anwendung: