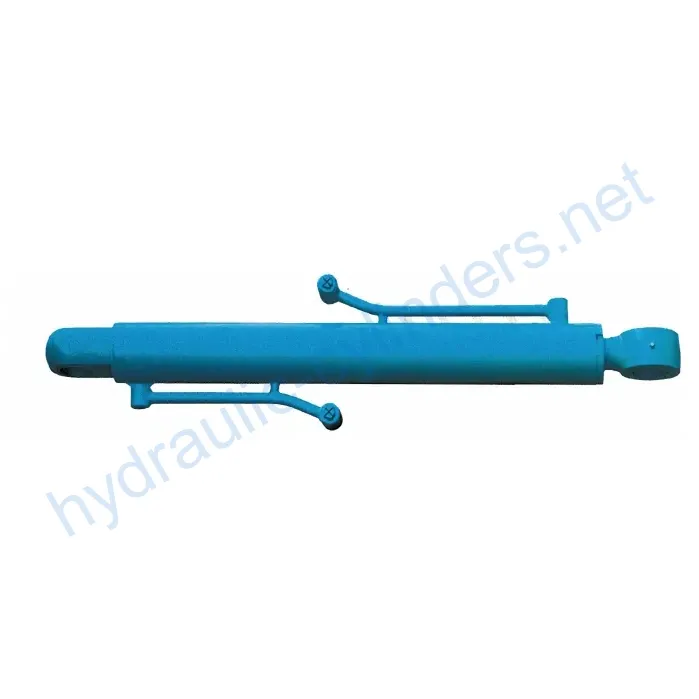

Bucket Cylinder For Kobelco Large Excavator SK450-6-6E

Ως ένας από τους κατασκευαστές, προμηθευτές και εξαγωγείς υδραυλικών κυλίνδρων μηχανικών προϊόντων, προσφέρουμε υδραυλικούς κυλίνδρους και πολλά άλλα προϊόντα.

Παρακαλούμε επικοινωνήστε μαζί μας για λεπτομέρειες.

Ταχυδρομείο:sales@hydraulic-cylinders.net

Κατασκευαστής προμηθευτής εξαγωγέας υδραυλικών κυλίνδρων.

Bucket Cylinder For Kobelco Large Excavator SK450-6-6E

Introduction

The bucket cylinder for Kobelco large excavator SK450-6-6E is a specially designed hydraulic cylinder primarily used to control the movement of the bucket in heavy machinery such as excavators, backhoe excavators, and front-end loaders. Its main function is to enable lifting, lowering, and tilting of the bucket, facilitating various material handling tasks. In the hydraulic system, the bucket cylinder achieves precise control of the bucket’s movement through changes in hydraulic oil pressure, enabling operators to handle heavy loads efficiently and adapt to complex working environments and diverse operational needs.

Features

- High strength and durability: Usually made of high-strength steel or aluminum, it can withstand high pressure and heavy loads and adapt to harsh working environments. The design considers wear resistance and corrosion resistance, extending service life.

- Efficient hydraulic operation: Smooth extension and contraction actions are achieved by utilizing hydraulic oil pressure, enabling quick response to operating commands and providing powerful pushing and pulling forces, suitable for handling heavy loads and complex operational tasks.

- Various types: Single acting (hydraulic used in one direction only) or double acting (hydraulic used in both directions) cylinders can be selected according to requirements to meet different operating needs. Some models are telescopic, allowing larger expansion without increasing external dimensions, suitable for space-limited applications.

- Highly adaptable: Our product can perfectly replace these hydraulic cylinders.

Εφαρμογή

The bucket cylinder has a wide range of applications in various industries. Some of the common applications are:

- Construction equipment: In excavators, they are crucial for digging, loading, and moving soil or debris. In backhoe excavators, the bucket cylinder helps with both digging and lifting.

- Agricultural machinery: Used in front-end loaders, they scoop, lift, and transport soil, hay, and other materials.

- Excavators: The bucket cylinder enables the digging action by allowing the bucket to penetrate the soil.

- Loaders: In front-end loaders, they help with lifting and dumping cargo efficiently.

Our bucket cylinder is perfect for these applications and more.

Design Considerations and Selection Standards

The bucket cylinder is an important component in hydraulic systems, and its design considerations and selection standards are crucial for ensuring optimal performance. Some of the key design considerations include:

- Bearing capacity: The cylinder must be able to withstand the load placed on it without bending or breaking.

- Sealing: Proper sealing is essential for preventing oil leakage and ensuring optimal performance.

- Durability: The cylinder must be made of high-quality materials that are resistant to wear and corrosion to ensure a long service life.

- Safety: The cylinder must be designed with safety in mind, with features such as safety valves to prevent overloading.

- Maintainability: The cylinder must be easy to maintain and repair, with easy access to components and clear instructions for maintenance and repair.

Our bucket cylinder meets all of these design considerations, ensuring optimal performance and a long service life.

Sealing and Lubrication

The bucket cylinder uses various sealing components such as piston seals, rod seals, etc., made of wear-resistant materials such as polyurethane, nitrile rubber, etc. The sealing system must be properly lubricated, and the cylinder should be regularly maintained with the appropriate amount of hydraulic oil to ensure optimal performance.

Maintenance and Repair

Regular maintenance and repair are essential for ensuring optimal performance and a long service life of the bucket cylinder. Some of the common maintenance tasks include regular inspections, proper lubrication, and sealing replacement. Proper installation, lubrication, and adjustment are also essential for optimal performance. The use of proper installation fixtures to secure the cylinder, recommended inspection, repair, and replacement procedures, and the use of rebuild services can all help improve the life of the bucket cylinder.

Safety and Environmental Considerations

The bucket cylinder is an essential component in heavy machinery, and safety must be a top priority when using it. Proper handling, operation, and maintenance procedures should be followed to ensure optimal safety and environmental protection.

Common Faults and Troubleshooting

Common faults in the bucket cylinder include oil leakage, broken seals, and damaged rods. Proper inspection and maintenance can help prevent these faults. If faults do occur, proper troubleshooting and repair procedures should be followed to restore optimal performance. It is recommended to follow preventive measures to minimize potential problems.

About Our Company

We are a manufacturer of replacement hydraulic cylinders with a complete range of products. We are one of the leading manufacturers and wholesale dealers of hydraulic cylinders on the domestic and international markets. We adhere to the principle of excellent quality, rely on the industrialized production management strategy of fine manufacturing workshops, and continuously improve the manufacturing platform of our workshops with technological talents, digital high-end manufacturing equipment, and professional testing systems. We strive to provide high-efficiency, high-precision, and high-quality products to meet the diverse needs of our customers.

We are committed to providing our customers with professional, international certified, and customized services. Our production equipment and after-sales services are top-notch, ensuring optimal performance and a long service life of our products.

Author: lyl

Περιηγηθείτε στο εργοστάσιο VR:

Περιηγηθείτε στο εργοστάσιο VR με τα εξής

Υδραυλικός κύλινδρος Εφαρμογή: