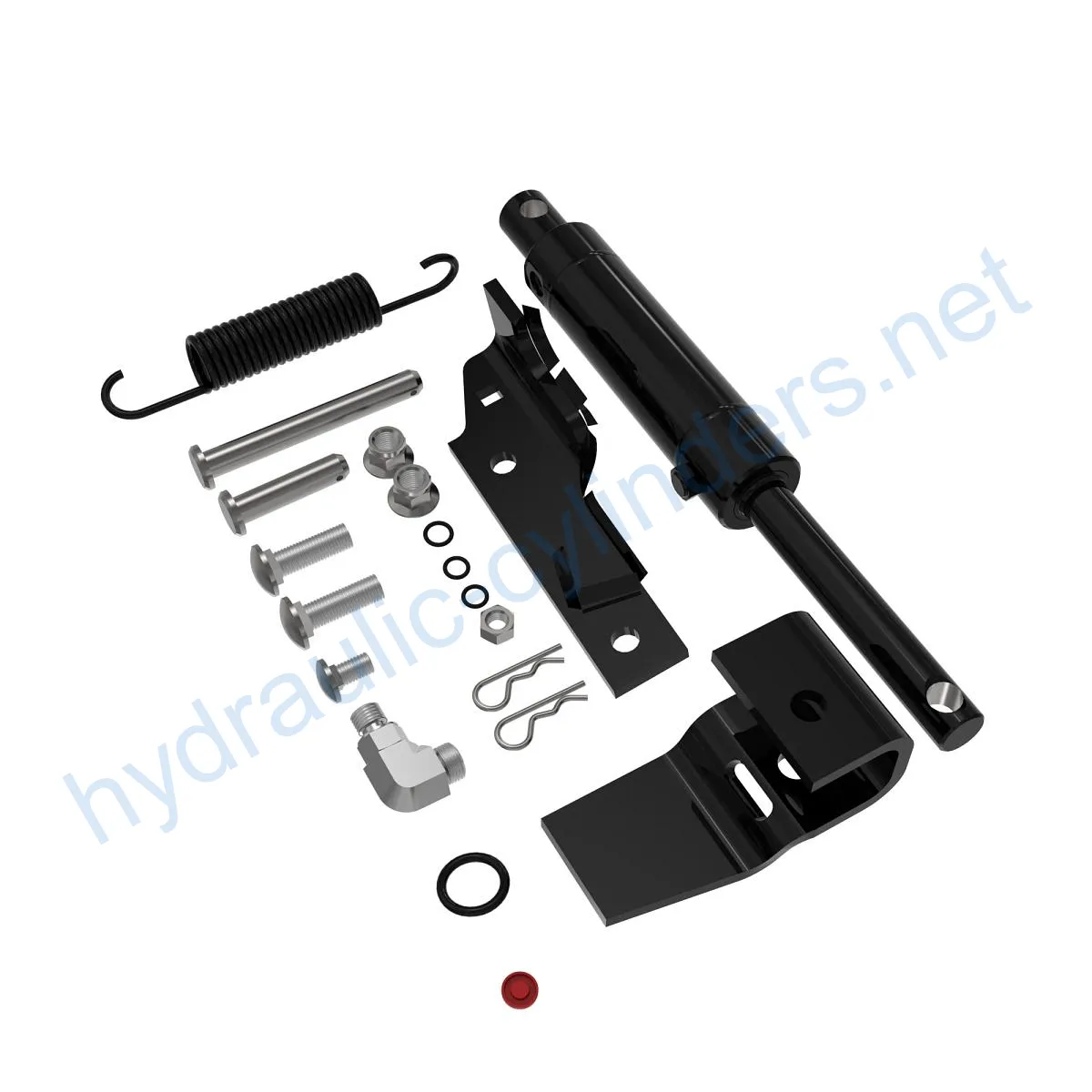

Replacement Of BLV10739 Hydraulic Lift Cylinder Kit

Como cilindros hidráulicos uno de los fabricantes, los surtidores y los exportadores de productos mecánicos, ofrecemos cilindros hidráulicos y muchos otros productos.

Póngase en contacto con nosotros para más información.

Correo:sales@hydraulic-cylinders.net

Fabricante proveedor exportador de cilindros hidráulicos.

Introduction

The Replacement Of BLV10739 Hydraulic Lift Cylinder Kit is a vital component designed to enhance the performance and functionality of various equipment models, including 54D IN., 60 IN. DECKS, 60D IN., 62 IN., 1023E, 1025R, and 1026R. This hydraulic cylinder kit is essential for maintaining the smooth operation of equipment by replacing damaged or worn-out cylinders.

Specifications

Weight: 7.7 lb

Height: 3.5 in

Width: 6 in

Length: 15.5 in

Features

Improved Equipment Performance

Replacing damaged or worn-out hydraulic cylinders can restore the equipment’s normal operational capability, ensuring optimum performance in various applications.

Enhanced Safety

Regularly replacing hydraulic cylinders reduces safety hazards caused by cylinder failure, ensuring the safety of both operators and equipment.

Overload Protection

New cylinder designs often incorporate better overload protection mechanisms, enhancing overall safety during operation.

Quick Installation

Modern hydraulic cylinders are designed for easy installation and replacement, minimizing downtime and maximizing efficiency.

Standardized Components

Many hydraulic cylinders are standardized, making it convenient to source replacement parts in the market.

Applications

The Replacement Of BLV10739 Hydraulic Lift Cylinder Kit finds its application in various scenarios:

Excavators

In excavators, the hydraulic cylinder may sustain damage due to prolonged usage or overload, necessitating replacement to restore normal operation.

Cranes

The crane’s boom hydraulic cylinder experiences wear and tear during frequent lifting and lowering processes, requiring regular replacement to ensure safety.

Tractors

The front-end loader hydraulic cylinder in tractors may develop leaks or experience performance degradation due to continuous lifting and tilting operations, demanding replacement.

Harvesters

During the harvesting process, the hydraulic system experiences high pressure, and fatigue may lead to cylinder damage, necessitating timely replacement to maintain operational efficiency.

Automated Production Lines

Hydraulic cylinders are used to control robotic arms and other automated equipment. Cylinder failure can significantly impact production efficiency, requiring immediate replacement.

Die Casting Machines

In high-pressure and high-temperature environments, hydraulic cylinders in die casting machines may experience performance degradation. Regular replacement ensures product quality.

Mining Equipment

Hydraulic cylinders are employed in lifting and moving heavy loads in mining equipment. Regular inspection and replacement are necessary to prevent equipment failure due to harsh working conditions.

Bulldozers

The hydraulic cylinder wear on the bulldozer’s blade can lead to a decrease in pushing capacity. Timely replacement is crucial to maintain operational efficiency.

Maintenance Tasks

To ensure the longevity and optimal performance of the Replacement Of BLV10739 Hydraulic Lift Cylinder Kit, the following maintenance tasks should be carried out:

Regular Inspection

Periodic inspection of the hydraulic cylinder helps identify potential issues early on and prevents further damage.

Proper Lubrication

Appropriate lubrication ensures smooth operation and reduces friction, extending the lifespan of the cylinder.

Seal Replacement and Calibration Check

Replacing seals and conducting calibration checks on the hydraulic cylinder is essential for maintaining its efficiency and preventing leaks.

Safety Considerations and Environmental Factors

When working with hydraulic cylinders, it is crucial to prioritize safety measures. Proper usage of safety equipment and adherence to safety protocols minimize the risk of accidents and injuries. Additionally, considering environmental factors such as leakage prevention and eco-friendly lubricants contributes to sustainable operations.

Troubleshooting and Common Issues

It is important to diagnose and address any problems that may arise with the Replacement Of BLV10739 Hydraulic Lift Cylinder Kit. Common issues include:

Leakage

If the hydraulic cylinder is leaking, it is necessary to inspect and replace seals or other components accordingly.

Poor Performance

If the cylinder’s performance is inadequate, it may be caused by internal faults or wear and tear. Troubleshooting techniques should be employed to identify and resolve the issue effectively.

Noise or Vibrations

Noise or excessive vibrations can indicate problems within the hydraulic system. These issues should be investigated and resolved promptly to prevent further damage.

Failure to Extend or Retract

If the cylinder fails to extend or retract as expected, it may be due to hydraulic fluid issues, misalignment, or mechanical faults. Troubleshooting steps should be followed to rectify the problem.

Preventive Measures

To minimize potential problems, regular maintenance and inspection are essential. Proper lubrication, alignment checks, and seal replacements should be carried out proactively.

Design Considerations and Selection Criteria

When considering the design and selection of hydraulic cylinders, several crucial factors should be taken into account:

Load-Bearing Capacity

The hydraulic cylinder should be selected based on its ability to withstand the intended load and operate safely within the specified parameters.

Sealing Capability

The cylinder’s seals should effectively prevent any leakage and maintain the hydraulic system’s integrity.

Durability

The hydraulic cylinder should be constructed with durable materials and designed to withstand the demands of the intended application.

Safety

Design features that prioritize safety, such as overload protection mechanisms and redundant systems, are crucial for maintaining a safe working environment.

Maintainability

Consideration should be given to the ease of maintenance, including accessibility for inspection, repair, and component replacement.

Sealing and Lubrication

The Replacement Of BLV10739 Hydraulic Lift Cylinder Kit incorporates various sealing and lubrication measures to ensure optimal performance:

Sealing components, such as piston seals and rod seals, are made from wear-resistant materials like polyurethane and nitrile rubber. The cylinder body and threaded ends undergo meticulous surface treatment to enhance wear resistance. Proper lubrication is vital for the smooth operation of the cylinder, and regular application of hydraulic oil ensures optimal performance.

Regular Inspection and Preventive Maintenance

To prolong the lifespan of the Replacement Of BLV10739 Hydraulic Lift Cylinder Kit and minimize potential issues, the following measures should be taken:

Correct Installation

Providing proper alignment guidance during installation, using appropriate installation brackets to secure the cylinder, and following recommended inspection, repair

Visite nuestra fábrica de RV:

Haga un recorrido por nuestra fábrica de RV con lo siguiente

Cilindro hidráulico Aplicación: