Short Forklift Lift Cylinder Short Main Lift Cylinder On Forklift

Como cilindros hidráulicos uno de los fabricantes, los surtidores y los exportadores de productos mecánicos, ofrecemos cilindros hidráulicos y muchos otros productos.

Póngase en contacto con nosotros para más información.

Correo:sales@hydraulic-cylinders.net

Fabricante proveedor exportador de cilindros hidráulicos.

Short Forklift Lift Cylinder Short Main Lift Cylinder On Forklift

The Short Forklift Lift Cylinder is designed to tackle short lifting tasks effortlessly, delivering the power and precision needed to optimize your material handling operations.

Featuring a robust design, this hydraulic cylinder can withstand heavy loads, frequent use, and challenging operating conditions. Built for durability, it ensures reliable performance while minimizing downtime related to maintenance or repairs.

With exceptional resistance to wear, corrosion, and contamination, the Short Forklift Lift Cylinder maintains peak performance throughout its lifespan. Engineered to endure harsh elements, it effectively shields itself from moisture, debris, and other contaminants that could compromise its functionality.

For those seeking a reliable lifting solution, this hydraulic cylinder is your ideal choice, ensuring efficiency and longevity in every operation.

Cilindro hidráulico de elevación corta para carretillas elevadoras Parámetros:

|

|

| Nombre del cilindro | número de dibujo | diámetro interior (D) | diámetro de la varilla (d) | ictus (S) | Distancia de instalación (L) | presión de trabajo | Dimensiones de la interfaz (M) | peso |

| Cilindro de elevación corto | RC25N480-800000-000A | Φ75 | Φ60 | 800 | 1065 | 18,1MPa | M22*1.5 | 36 kg |

| Cilindro de elevación corto | X35N480-800000-001A | Φ95 | Φ80 | 800 | 1065 | 18,1MPa | M22*1.5 | 48,7 kg |

|

|

| Nombre del cilindro | número de dibujo | diámetro interior (D) | diámetro de la varilla (d) | ictus (S) | Distancia de instalación (L) | presión de trabajo | Dimensiones de la interfaz (M) | peso |

| Cilindro de elevación corto | N30N450-800000-002A | Φ85 | Φ70 | 777 | 1015 | 18,1MPa | M22*1.5 | 45,5 kg |

| Cilindro de elevación corto | 3U3H-800000-001A | Φ85 | Φ70 | 777 | 1015 | 18,1MPa | M22*1.5 | 45,5 kg |

| Cilindro de elevación corto | N35N450-800000-003A | Φ95 | Φ80 | 775 | 1013 | 18,1MPa | M22*1.5 | 54 kg |

Desbloquee la eficiencia y la precisión con el cilindro hidráulico:

Experimente la verdadera potencia de la tecnología hidráulica con el cilindro hidráulico. Este extraordinario dispositivo está diseñado para ofrecer precisión y fiabilidad en una amplia gama de aplicaciones. Desde maquinaria industrial hasta equipos de construcción, el cilindro hidráulico es la clave para optimizar el rendimiento y lograr resultados extraordinarios. Descubra cómo esta potente herramienta puede revolucionar sus operaciones.

- Ingeniería de precisión: El cilindro hidráulico está meticulosamente diseñado para proporcionar un control preciso sobre el movimiento y la fuerza. Con su avanzado diseño y su construcción de alta calidad, garantiza un rendimiento exacto y repetible, lo que le permite lograr los resultados deseados con una precisión excepcional.

- Mayor eficiencia: Diga adiós a las ineficiencias y al rendimiento desigual. El cilindro hidráulico optimiza la utilización de la potencia hidráulica, maximizando la eficiencia y la productividad. Experimente movimientos suaves y controlados que reducen el derroche de energía y mejoran el rendimiento general del sistema.

Main Lift Cylinder On Forklift Application:

What Are The Common Causes Of A Forklift Lift Cylinder Leaking?

Certainly! Here’s a more detailed exploration of the common causes of a forklift lift cylinder leaking:

1. Worn Seals

Material Degradation: Seals are typically made of rubber or other elastomers that can degrade over time due to heat, pressure, and hydraulic fluid exposure. This degradation can lead to cracks or hardening, compromising their sealing ability.

Environmental Factors: Exposure to extreme temperatures, UV light, or harsh chemicals can accelerate seal wear, increasing the likelihood of leaks.

2. Damaged Cylinder Rod

Surface Imperfections: Any scratches, nicks, or corrosion on the cylinder rod can create a pathway for hydraulic fluid to escape. These imperfections can occur from improper handling, contact with debris, or general wear.

Rod Misalignment: If the cylinder rod is not aligned correctly, it can cause uneven wear on the seals, leading to premature failure and leaks.

3. Loose Fittings

Vibration and Movement: Forklifts are subjected to constant vibrations and movements, which can loosen hydraulic fittings over time. Regular checks are necessary to ensure all connections are secure.

Installation Issues: If fittings were not installed correctly during maintenance or repair, they may become loose and lead to leaks.

4. Overpressure

Hydraulic System Issues: If the hydraulic system is overpressurized due to malfunctioning components or improper adjustments, it can put excessive stress on seals and fittings, resulting in leaks.

Pressure Relief Valve Failure: A malfunctioning pressure relief valve can fail to regulate the system pressure, leading to increased stress on the lift cylinder.

5. Contamination

Debris in Hydraulic Fluid: Dirt, metal shavings, or other contaminants in the hydraulic fluid can damage seals and cause leaks. Regular fluid changes and filtration can help mitigate this issue.

Water Contamination: Water entering the hydraulic system can lead to rust and corrosion, further damaging seals and components.

6. Age and Wear

Lifecycle of Components: As hydraulic systems age, components naturally wear out. Older forklifts or those with heavy use are more prone to leaks due to general wear and tear.

Fatigue of Materials: Repeated cycles of pressurization and depressurization can lead to material fatigue, resulting in failures in seals and other components.

7. Improper Maintenance

Neglecting Regular Checks: Failing to inspect and maintain the hydraulic system can lead to undetected wear and leaks. Scheduled maintenance is essential for identifying potential issues before they escalate.

Use of Incorrect Fluids: Using hydraulic fluids that do not meet manufacturer specifications can lead to seal damage and increased wear on hydraulic components.

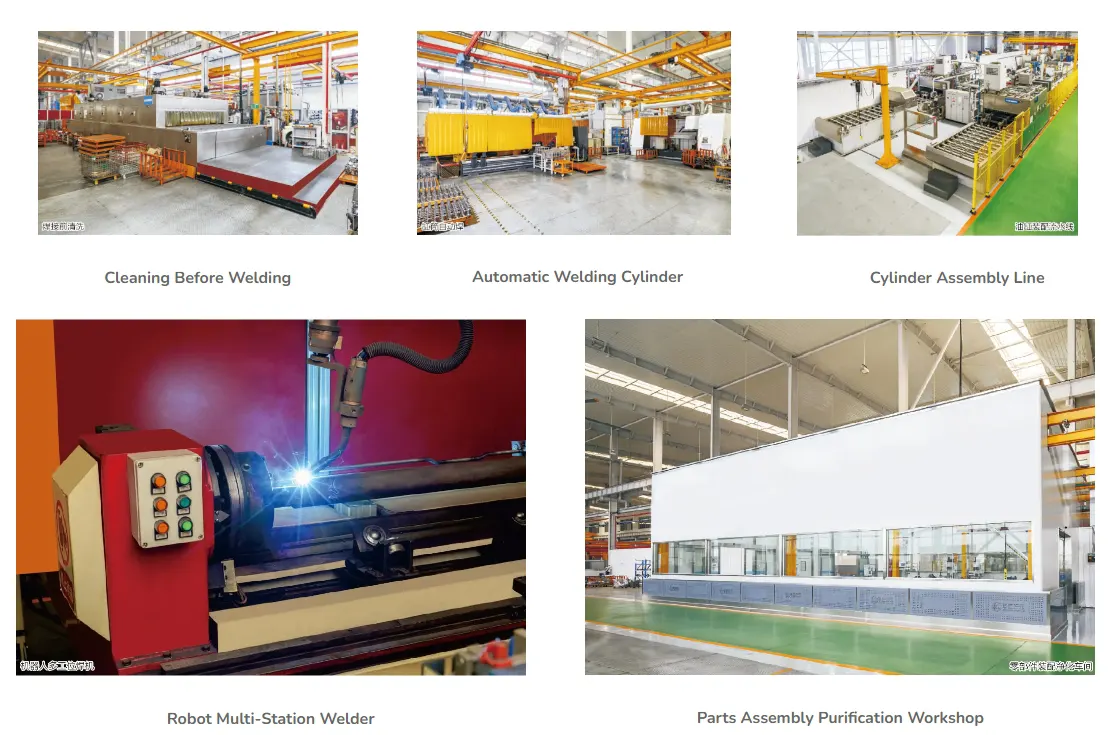

Capacidad de la fábrica:

(1) Montaje

Our facility boasts a top-tier independent research and development assembly platform dedicated to hydraulic cylinder production. We operate four semi-automatic lifting cylinder assembly lines and one fully automatic tilt cylinder assembly line, with an impressive annual production capacity of 1 million cylinders.

In our specialized cylinder workshop, we utilize a semi-automatic cleaning assembly system designed for various specifications, capable of producing 200,000 cylinders annually. Our workshop is equipped with advanced CNC machining equipment, a machining center, high-precision cylinder processing tools, robot welding machines, automatic cleaning systems, and an automated cylinder assembly line. Additionally, we have a fully automated painting production line.

With over 300 pieces of critical equipment, our optimal resource allocation ensures that we meet the strict accuracy and quality standards required by our clients. This commitment to efficiency and precision positions us as a leader in the hydraulic cylinder industry.

(2) Mecanizado

Our machining shop features state-of-the-art equipment, including a customized inclined rail turning center, a precision machining center, a high-speed honing machine, and advanced welding robots. This sophisticated setup enables us to efficiently process cylinder tubes with a maximum inner diameter of 400mm and a length of up to 6 meters.

With our cutting-edge technology, we ensure high-quality machining that meets the diverse needs of hydraulic cylinder production.

(3) Soldadura

(4) Painting & Coating

Our facility features advanced automatic water-based paint coating lines specifically designed for small and medium-sized cylinders. These lines utilize robotic technology for efficient loading, unloading, and spraying, achieving a remarkable production capacity of 4,000 pieces per shift.

In addition, we operate a semi-automatic paint production line for large cylinders, powered by a robust power chain, with a designed capacity of 60 cases per shift. This combination of automation and efficiency ensures high-quality finishes for all our hydraulic cylinders.

(5) Pruebas

Disponemos de instalaciones de inspección y bancos de pruebas de primera clase para garantizar que el rendimiento del cilindro cumple los requisitos.

We are a renowned manufacturer of cilindros hidráulicos, recognized as one of the best in the industry. Our extensive product line includes a wide range of hydraulic cylinders tailored to meet various applications. In addition to hydraulic cylinders, we also provide high-quality agricultural gearboxes, ensuring our customers have access to comprehensive solutions for their machinery needs.

With a commitment to excellence, we have successfully exported our products to clients worldwide, earning a strong reputation for superior product quality and exceptional after-sales service. Our dedication to customer satisfaction has positioned us as a trusted partner in both domestic and international markets.

Why Choose Us?

Professional Expertise: Our team comprises industry professionals with extensive knowledge and experience in hydraulic systems, ensuring that we deliver top-notch products and services.

International Certifications: We adhere to strict quality standards and hold various international certifications, demonstrating our commitment to delivering reliable and safe hydraulic solutions.

Custom Solutions: We understand that each customer’s needs are unique. That’s why we offer customized hydraulic cylinders and gearboxes tailored to meet specific requirements.

Advanced Production Equipment: Our state-of-the-art manufacturing facilities utilize the latest technology and equipment, enabling us to produce high-quality products efficiently.

Comprehensive After-Sales Support: Our commitment to our customers extends beyond the sale. We provide ongoing support and maintenance services to ensure optimal performance of our products.

We invite customers from around the globe to reach out to us for business negotiations, information exchange, and collaboration opportunities. Together, we can achieve greater success in the hydraulic industry!

Visite nuestra fábrica de RV:

Haga un recorrido por nuestra fábrica de RV con lo siguiente

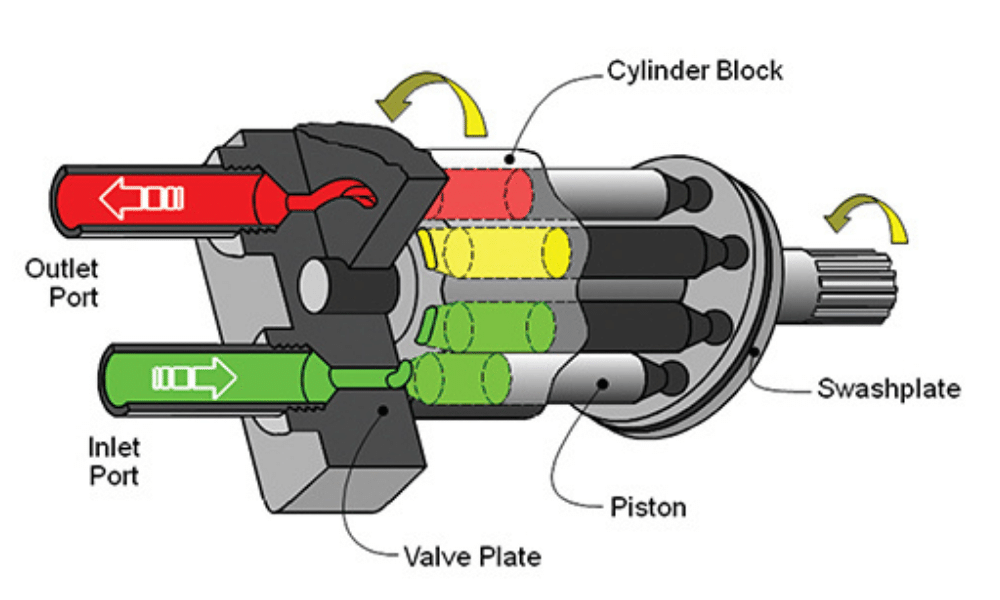

¿Cómo funciona el cilindro hidráulico de una carretilla elevadora?

Cilindro hidráulico Aplicación: