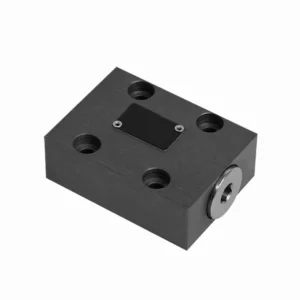

RVP Series Check Hydraulic Valve

Üheks hüdrosilindrite tootjaks, tarnijaks ja mehaaniliste toodete eksportijaks pakume hüdrosilindreid ja paljusid teisi tooteid.

Palun võtke meiega ühendust üksikasjade saamiseks.

Post:sales@hydraulic-cylinders.net

Tootja tarnija eksportija hüdrosilindrid.

RVP Series Check Hydraulic Valve

The RVP series check hydraulic valve is a manifold-mounted valve that allows fluid to flow in one direction and prevents it from flowing in the opposite direction. It is a critical component in many hydraulic systems, including mobile equipment, construction machinery, and industrial automation equipment.

The RVP series check hydraulic valve is a high-quality, durable valve that is ideal for a wide range of hydraulic applications. It is easy to use and maintain and provides excellent flow control and pressure retention. The RVP series is a great option if you are looking for a reliable and efficient check valve for your hydraulic system.

RVP Series Check Hydraulic Valve Key Characteristics:

- High-pressure Capacity: The RVP series check hydraulic valve can withstand up to 5000 psi operating pressures.

- Low-pressure Drop: The RVP series check hydraulic valve has a very low-pressure drop, which maximizes system efficiency.

- Excellent Flow Control: The RVP series check hydraulic valve provides precise flow control, even at high flow rates.

- Durable Construction: The RVP series check hydraulic valve is made from high-quality materials and is built to withstand the rigors of demanding hydraulic applications.

- Easy To Maintain: The RVP series check hydraulic valve is easy to disassemble and inspect, making it simple to maintain and repair.

RVP Series Check Hydraulic Valve Parameter:

| Size | 6 | 10 | 16 | 22 | |

| Weight | kg | 0.8 | 2.3 | 8.5 | 13 |

| Max. flow-rate | L/min | 42 | 100 | 200 | 400 |

| Max. operating pressure | bar | to 315 | |||

| Crack pressure | bar | 0.5,3,5 | |||

| Viscosity range | mm2/s | 2.8 to 500 | |||

| Fluid temperature range | ℃ | -20 to +70 | |||

| Fluid | Mineral oil suitable for NBR and FKM seal | ||||

| Phosphate ester for FKM seal | |||||

| Degree of contamination | Maximum permissible degree of fluid contamination: Class 9. NAS 1638 or 20/18/15, ISO4406 | ||||

RVP Series Check Hydraulic Valve Advantages:

• Conical seat valve

• Sub-plate mounting

• Multiple levels of opening pressure

Usage Method Of RVP Series Check Hydraulic Valve:

The RVP series check hydraulic valve is typically used in the following applications:

- To prevent backflow in hydraulic systems

- To protect hydraulic components from damage

- To control the flow of hydraulic fluid in one direction

- To hold hydraulic pressure in a system

Maintenance Of RVP Series Check Hydraulic Valve:

The RVP series check hydraulic valve requires minimal maintenance. However, it is important to inspect the valve regularly for signs of wear or damage. If any problems are found, the valve should be replaced immediately.

Here are some tips for maintaining your RVP series check hydraulic valve:

- Inspect the valve regularly for signs of wear or damage. Look for cracks, leaks, and other imperfections.

- Clean the valve regularly with a mild soap and water solution. Avoid using harsh chemicals or solvents.

- Lubricate the moving parts of the valve with a light-duty oil or grease.

- If the valve is not working properly, replace it immediately.

How Does A Double Acting Hydraulic Cylinder Work?

A double-acting hydraulic cylinder is a type of hydraulic cylinder that can produce force in both directions. It has two ports, one for the inlet and one for the outlet of hydraulic fluid. When pumped into one port, hydraulic fluid pushes the piston in the opposite direction. When hydraulic fluid is pumped into the other port, it pushes the piston in the opposite direction.

Here is a simplified explanation of how a double-acting hydraulic cylinder works:

- The piston is in the center of the cylinder bore.

- Hydraulic fluid is pumped into the port on one side of the piston.

- The hydraulic fluid pressure pushes the piston in the opposite direction.

- The piston rod extends from the cylinder and transmits the force to the load being moved.

- To retract the piston, hydraulic fluid is pumped into the port on the other side of the piston.

- The hydraulic fluid pressure pushes the piston in the opposite direction.

- The piston rod retracts into the cylinder.

Double-acting hydraulic cylinders are used in a wide range of applications, including:

- Construction machinery (e.g., excavators, bulldozers, cranes)

- Industrial automation equipment (e.g., robots, presses, conveyors)

- Mobile equipment (e.g., forklifts, backhoes, tractors)

- Aerospace and defense equipment (e.g., aircraft landing gear, missile launch systems)

Tehase võimekus ja suutlikkus:

(1) Kokkupanek

Meil on esmaklassiline sõltumatu teadus- ja arendustegevuse montaažiplatvorm. Hüdrosilindrite tootmistöökojas on neli poolautomaatset tõstesilindrite koosteliini ja üks automaatne kallutussilindrite koosteliin, mille kavandatud aastane tootmisvõimsus on 1 miljon tükki. Spetsiaalsete silindrite töökoda on varustatud erinevate spetsifikatsioonidega poolautomaatse puhastusmontaažisüsteemiga, mille kavandatud aastane tootmisvõimsus on 200 000 ja mis on varustatud kuulsate CNC-töötlemisseadmete, mehaanilise töötlemise keskuse, suure täpsusega silindrite töötlemise eriseadmete, robotkeevitusmasina, automaatse puhastusmasina, automaatse silindri kokkupanemise masina ja automaatse värvimise tootmisliiniga. Olemasolevad kriitilised seadmed rohkem kui 300 komplekti (komplekti). Seadmete ressursside optimaalne jaotamine ja tõhus kasutamine tagavad toodete täpsusnõuded ja vastavad toodete kvaliteedinõuetele.

(2) Töötlemine

Töödeldav töökoda on varustatud kohandatud kallutatud rööpse treipingi keskuse, mehaanilise keskuse, kiire lihvimismasina, keevitusroboti ja muude seotud seadmetega, mis suudavad töödelda silindritorusid, mille maksimaalne siseläbimõõt on 400 mm ja maksimaalne pikkus on 6 meetrit.

(3) Keevitamine

(4) Värvimine ja katmine

Väikese ja keskmise suurusega silindri automaatse veepõhise värvipinnakattega liinide abil, et saavutada automaatne robotlaadimine ja mahalaadimine ning automaatne pihustamine, projekteerimisvõimsus 4000 tükki vahetuse kohta;

Meil on ka poolautomaatne suurte balloonide värvimise tootmisliin, mis töötab jõukettaga ja mille projekteerimisvõimsus on 60 kasti ühe vahetuse kohta.

(5) Testimine

Meil on esmaklassilised kontrolliseadmed ja katsestendid, et tagada silindri jõudlus vastavus nõuetele.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding põllumajanduslikud käigukastid. Oleme eksportinud oma tooteid klientidele üle maailma ja teeninud hea maine tänu meie suurepärasele tootekvaliteedile ja müügijärgsele teenindusele. Me tervitame kliente kodus ja välismaal, et võtta meiega ühendust, et pidada läbirääkimisi äri, vahetada teavet ja teha meiega koostööd!

Tehke ekskursioon meie VR-tehases:

Tehke ekskursioon meie VR-tehases koos järgmisega

Hüdrosilindri kasutamine: