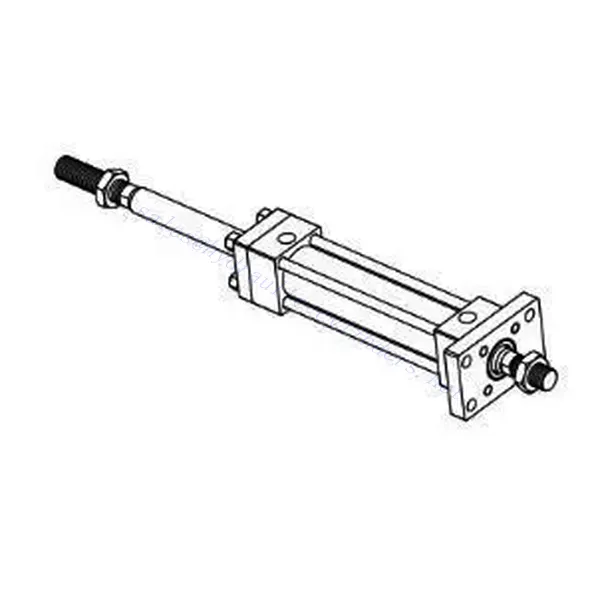

FA Double Shaft Front Flange Type Heavy Rod hüdrosilinder

Üheks hüdrosilindrite tootjaks, tarnijaks ja mehaaniliste toodete eksportijaks pakume hüdrosilindreid ja paljusid teisi tooteid.

Palun võtke meiega ühendust üksikasjade saamiseks.

Post:sales@hydraulic-cylinders.net

Tootja tarnija eksportija hüdrosilindrid.

FA Double Shaft Front Flange Type Heavy Rod hüdrosilinder

The FA double shaft front flange type heavy rod hydraulic cylinder is a rugged, high-performance hydraulic element designed to handle demanding industrial applications quickly. With its durable construction, dual shaft design, and front flange configuration, this hydraulic cylinder offers exceptional power, accuracy, and reliability. Whether you need to lift, push, or pull heavy loads, the FA two-shaft front flange heavy rod hydraulic cylinder performs in challenging conditions, making it an indispensable tool in every industry.

Essential Characteristics Of Heavy Rod Hydraulic Cylinder:

Vastupidav konstruktsioon: This hydraulic cylinder can withstand extreme conditions thanks to its robust construction of high-quality materials. Its rugged design ensures service life, reliability, and wear resistance, enabling it to handle heavy loads, high pressures, and harsh working environments.

Double Shaft Design: The cylinder’s dual-axis configuration provides enhanced stability, controlled motion, and precise positioning. There are shafts at both ends of the cylinder, allowing for simultaneous push and pull action, making it ideal for applications requiring two-way forces.

Front Flange Configuration: The FA double shaft front flange type heavy rod hydraulic cylinder’s front flange design provides a simple and convenient installation option. Flanges can be attached directly to equipment or machinery, simplifying installation and ensuring proper alignment.

FA Double Shaft Front Flange Type Heavy Rod Hydraulic Cylinder Parameter:

FA Double Shaft Front Flange Type Heavy Rod hüdrosilinder Kasutamise meetod:

Mounting: First, safely install the FA double shaft front flange type heavy rod hydraulic cylinder using the appropriate bracket or fixture. Ensure proper alignment and stability during installation to prevent cylinder misalignment or excessive stress.

Hydraulic System Integration: Connect the hydraulic line to the cylinder according to the manufacturer’s instructions and guidelines. The cylinder is integrated into the hydraulic system by connecting it to a suitable pump or power unit. Ensure cylinder specifications and operating requirements are met.

Control and Operation: The control valve in the hydraulic system regulates the flow of hydraulic oil into and out of the cylinder. Adjust the control Settings to achieve the desired linear motion and force output. Test the movement of the cylinder to verify its function and responsiveness.

FA Double Shaft Front Flange Type Heavy Rod hüdrosilinder Maintenance:

Regular maintenance is essential to ensure optimal performance and longevity of the FA double shaft front flange type heavy rod hydraulic cylinder. Follow these maintenance guidelines:

Regular Inspection: Perform routine inspections to identify signs of wear, damage or leaks. Check cylinder blocks, shafts, seals and other components for abnormalities. Resolve any issues promptly to prevent further injury or operational inefficiencies.

Lubrication: Apply the recommended lubricant to the moving parts of the cylinder, including the shafts and seals. Regular lubrication minimizes friction, reduces wear, and ensures smooth operation. Follow the manufacturer’s guidelines for lubrication intervals and use the appropriate lubricant type.

Seal Replacement: If seals are found to be deteriorating or leaking, replace seals with genuine parts approved by the manufacturer. Damaged or worn seals can compromise the cylinder’s performance and lead to hydraulic oil leakage.

Cleaning: Clean cylinders by removing dirt, debris, and other contaminants. Before reassembling, use a non-abrasive cleaner and make sure all parts are completely dry. Regular cleaning promotes optimal performance and prevents premature wear or damage.

How To Remove Hydraulic Cylinder From Chair?

To remove a hydraulic cylinder from a chair, follow the steps below:

- Safety Precautions: Before starting, ensure the chair is on a stable surface and won’t tip over. Wear appropriate personal protective equipment (PPE) such as gloves and safety glasses.

- Laske tool alla: If the chair has an adjustable height feature, lower it to its lowest position. This step will make it easier to access and remove the hydraulic cylinder.

- Locate the Cylinder Attachment Point: Examine the chair to identify the attachment point of the hydraulic cylinder. This can be at the base of the chair or underneath the seat.

- Remove the Retaining Clip: Many chairs use a retaining clip or ring to secure the hydraulic cylinder. Locate the retaining clip and use a flathead screwdriver or a pair of pliers to remove it. Be cautious as the clip may spring out when released.

- Separate the Cylinder from the Chair Base: Once the retaining clip is removed, you can detach the hydraulic cylinder from the chair base. Firmly grip the chair seat and lift it upward while applying gentle force to separate the cylinder from the ground. You may need to wiggle or twist the cylinder slightly to loosen it.

- Inspect and Clean: After removing the hydraulic cylinder, inspect it for any signs of damage, leaks, or wear. Check the attachment points on both the cylinder and the chair for any debris, dirt, or rust. Clean these areas using a mild cleaner or a cloth dampened with water.

- Reinstallation or Replacement: If you plan to reuse the hydraulic cylinder, ensure it is in good working condition and free from any defects. Apply a small amount of lubricant to the attachment points to facilitate smooth movement. Reverse the steps to reinstall the cylinder into the chair. If the cylinder is damaged or malfunctioning, it is recommended to replace it with a new one of the appropriate size and specifications.

Tehase võimekus ja suutlikkus:

(1) Kokkupanek

Meil on esmaklassiline sõltumatu teadus- ja arendustegevuse montaažiplatvorm. Hüdrosilindrite tootmistöökojas on neli poolautomaatset tõstesilindrite koosteliini ja üks automaatne kallutussilindrite koosteliin, mille kavandatud aastane tootmisvõimsus on 1 miljon tükki. Spetsiaalsete silindrite töökoda on varustatud erinevate spetsifikatsioonidega poolautomaatse puhastusmontaažisüsteemiga, mille kavandatud aastane tootmisvõimsus on 200 000 ja mis on varustatud kuulsate CNC-töötlemisseadmete, mehaanilise töötlemise keskuse, suure täpsusega silindrite töötlemise eriseadmete, robotkeevitusmasina, automaatse puhastusmasina, automaatse silindri kokkupanemise masina ja automaatse värvimise tootmisliiniga. Olemasolevad kriitilised seadmed rohkem kui 300 komplekti (komplekti). Seadmete ressursside optimaalne jaotamine ja tõhus kasutamine tagavad toodete täpsusnõuded ja vastavad toodete kvaliteedinõuetele.

(2) Töötlemine

Töödeldav töökoda on varustatud kohandatud kallutatud rööpse treipingi keskuse, mehaanilise keskuse, kiire lihvimismasina, keevitusroboti ja muude seotud seadmetega, mis suudavad töödelda silindritorusid, mille maksimaalne siseläbimõõt on 400 mm ja maksimaalne pikkus on 6 meetrit.

(3) Keevitamine

(4) Värvimine ja katmine

Väikese ja keskmise suurusega silindri automaatse veepõhise värvipinnakattega liinide abil, et saavutada automaatne robotlaadimine ja mahalaadimine ning automaatne pihustamine, projekteerimisvõimsus 4000 tükki vahetuse kohta;

Meil on ka poolautomaatne suurte balloonide värvimise tootmisliin, mis töötab jõukettaga ja mille projekteerimisvõimsus on 60 kasti ühe vahetuse kohta.

(5) Testimine

Meil on esmaklassilised kontrolliseadmed ja katsestendid, et tagada silindri jõudlus vastavus nõuetele.

We are one of the best heavy rod hydraulic cylinder manufacturers. We can offer wide heavy rod hydraulic cylinder stock. We also provide corresponding põllumajanduslikud käigukastid. Oleme eksportinud oma tooteid klientidele üle kogu maailma ja teeninud hea maine tänu meie suurepärasele tootekvaliteedile ja müügijärgsele teenindusele. Me tervitame soojalt kliente nii kodus kui ka välismaal, et võtta meiega ühendust, et pidada läbirääkimisi äri, vahetada teavet ja teha meiega koostööd!

Tehke ekskursioon meie VR-tehases:

Tehke ekskursioon meie VR-tehases koos järgmisega

Kuidas töötab kahveltõstuki hüdrosilinder?

Hüdrosilindri kasutamine: