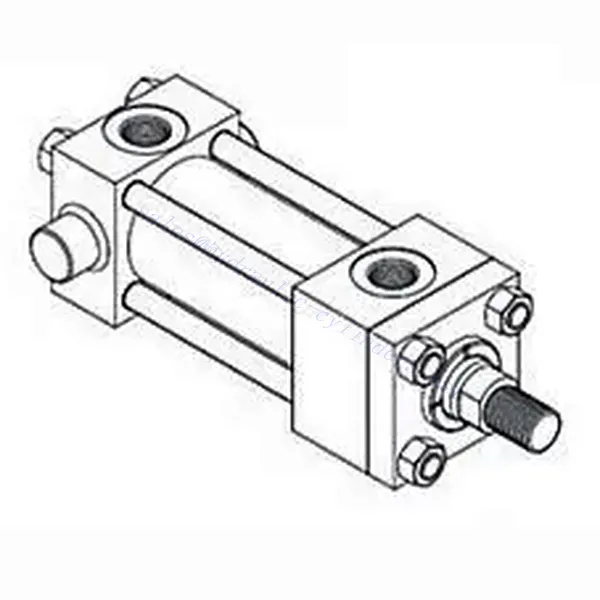

Keskmine fikseeritud telgjoatoru nelja vardaga hüdrosilinder

Üheks hüdrosilindrite tootjaks, tarnijaks ja mehaaniliste toodete eksportijaks pakume hüdrosilindreid ja paljusid teisi tooteid.

Palun võtke meiega ühendust üksikasjade saamiseks.

Post:sales@hydraulic-cylinders.net

Tootja tarnija eksportija hüdrosilindrid.

Keskmine fikseeritud telgjoatoru nelja vardaga hüdrosilinder

The middle fixed trunnion four rod hydraulic cylinder is a state-of-the-art hydraulic component designed to deliver exceptional power, stability, and precision in a wide range of industrial applications. With its innovative middle fixed trunnion design and four rod configuration, this four rod hydraulic cylinder offers superior load-bearing capacity, durability, and reliable performance, making it an essential asset in demanding hydraulic systems.

Essential Characteristics Of Four Rod Hydraulic Cylinder:

Middle Fixed Trunnion Design:

-

- The intermediate fixed trunnion design provides a safe and stable installation solution that ensures reliable operation even under heavy loads and extreme conditions.

- It simplifies the installation process and can be easily integrated into various hydraulic systems or equipment.

Four Rod Configuration:

-

- The four rod configuration enhances the bearing capacity of the cylinder, providing optimal stability and precise positioning.

- It enables the cylinder to effectively withstand side loads, providing exceptional resistance to torsion and lateral forces.

High Power Output:

-

- This four rod hydraulic cylinder has an impressive power output, allowing it to handle heavy loads easily.

- It provides superior power and thrust, making it suitable for applications requiring strength and lifting capacity.

Täpne kontroll:

-

- The four rod hydraulic cylinder with a fixed trunnion in the middle can accurately control the linear movement to ensure accurate positioning and smooth operation.

- It provides excellent stroke control, enabling operators to achieve the speed and precision required for specific tasks.

Middle Fixed Trunnion Four Rod Hydraulic Cylinder Parameter:

Keskmine fikseeritud telgjoatoru nelja vardaga hüdrosilinder Kasutamise meetod:

Paigaldamine ja paigaldamine:

-

- Consider load requirements and space constraints to determine the appropriate installation location of the four rod hydraulic cylinder within the system or equipment.

- Ensure the mounting surface is clean, level, and able to support the weight of the cylinder.

- Secure the middle fixing trunnons to the mounting surface using recommended bolts or fasteners.

Hydraulic Connections:

-

- Connect the hydraulic supply line to the cylinder port, ensuring proper seal to prevent leakage.

- Follow the manufacturer’s recommendations for the type of hydraulic oil and fill the system to the recommended level.

Operation:

-

- Activate the hydraulic system and control the movement of the cylinder using a hydraulic control valve or other suitable control mechanism.

- Adjust flow and pressure Settings to achieve the desired speed and force output.

- Regularly monitor cylinder operation for abnormal behavior, such as leakage, overheating, or unusual noise.

Keskmine fikseeritud telgjoatoru nelja vardaga hüdrosilinder Maintenance:

Regular Inspection:

-

- Perform routine visual inspections to check for signs of wear, leakage, or damage.

- Inspect rod surfaces, seals, and mounting connections for abnormalities and address any problems promptly.

Lubrication:

-

- Follow the manufacturer’s lubrication interval guidelines and use the recommended lubricant to ensure smooth operation.

- Lubricate rods, seals, and other moving parts to reduce friction and extend the service life of four-bar hydraulic cylinders.

Seal Replacement:

-

- Over time, seals may wear out and need to be replaced. If a leak is detected, carefully remove the old seal and install the new seal according to the manufacturer’s specifications.

How Fast Can A Hydraulic Cylinder Move?

The speed at which a hydraulic cylinder can move depends on several factors, including the size and design of the cylinder, the hydraulic system’s pressure and flow rate, and the load being moved.

In general, hydraulic cylinders are known for their ability to provide both high force and precise control, but their maximum speed is typically lower compared to other types of actuators. The speed of a hydraulic cylinder is determined by the rate at which hydraulic fluid is supplied to or released from the cylinder chamber.

Here are a few factors that can affect the speed of a hydraulic cylinder:

- System Design and Components: The design of the hydraulic system, including the pump, valves, and piping, can impact the speed of the cylinder. The system should be properly sized and configured to provide adequate flow rate and pressure to achieve the desired speed.

- Cylinder Diameter and Stroke Length: The diameter and stroke length of the cylinder also play a role in determining its speed. Generally, larger diameter cylinders tend to move more slowly than smaller ones due to the more extensive hydraulic fluid required to fill or empty the cylinder chamber.

- Flow Rate and Pressure: The flow rate and pressure of the hydraulic fluid supplied to the cylinder are critical factors in determining the cylinder’s speed. Increasing the flow rate or pressure can result in faster movement, while reducing them will slow down the cylinder.

- Load and Friction: The weight and friction of the shipment being moved can affect the speed of the cylinder. Heavier loads may require more force, which can reduce the overall rate of the cylinder. Additionally, increased friction within the system, such as from seals or misalignment, can also impact the speed.

Tehase võimekus ja suutlikkus:

(1) Kokkupanek

Meil on esmaklassiline sõltumatu teadus- ja arendustegevuse montaažiplatvorm. Hüdrosilindrite tootmistöökojas on neli poolautomaatset tõstesilindrite koosteliini ja üks automaatne kallutussilindrite koosteliin, mille kavandatud aastane tootmisvõimsus on 1 miljon tükki. Spetsiaalsete silindrite töökoda on varustatud erinevate spetsifikatsioonidega poolautomaatse puhastusmontaažisüsteemiga, mille kavandatud aastane tootmisvõimsus on 200 000 ja mis on varustatud kuulsate CNC-töötlemisseadmete, mehaanilise töötlemise keskuse, suure täpsusega silindrite töötlemise eriseadmete, robotkeevitusmasina, automaatse puhastusmasina, automaatse silindri kokkupanemise masina ja automaatse värvimise tootmisliiniga. Olemasolevad kriitilised seadmed rohkem kui 300 komplekti (komplekti). Seadmete ressursside optimaalne jaotamine ja tõhus kasutamine tagavad toodete täpsusnõuded ja vastavad toodete kvaliteedinõuetele.

(2) Töötlemine

Töödeldav töökoda on varustatud kohandatud kallutatud rööpse treipingi keskuse, mehaanilise keskuse, kiire lihvimismasina, keevitusroboti ja muude seotud seadmetega, mis suudavad töödelda silindritorusid, mille maksimaalne siseläbimõõt on 400 mm ja maksimaalne pikkus on 6 meetrit.

(3) Keevitamine

(4) Värvimine ja katmine

Väikese ja keskmise suurusega silindri automaatse veepõhise värvipinnakattega liinide abil, et saavutada automaatne robotlaadimine ja mahalaadimine ning automaatne pihustamine, projekteerimisvõimsus 4000 tükki vahetuse kohta;

Meil on ka poolautomaatne suurte balloonide värvimise tootmisliin, mis töötab jõukettaga ja mille projekteerimisvõimsus on 60 kasti ühe vahetuse kohta.

(5) Testimine

Meil on esmaklassilised kontrolliseadmed ja katsestendid, et tagada silindri jõudlus vastavus nõuetele.

Me oleme üks parimaid kergeid nelja vardaga hüdrosilindrite tootjaid. Me saame pakkuda terviklikku kerget nelja vardaga hüdrosilindri varu. Pakume ka vastavaid põllumajanduslikud käigukastid. Oleme eksportinud oma tooteid klientidele üle kogu maailma ja teeninud hea maine tänu meie suurepärasele tootekvaliteedile ja müügijärgsele teenindusele. Me tervitame soojalt kliente nii kodus kui ka välismaal, et võtta meiega ühendust, et pidada läbirääkimisi äri, vahetada teavet ja teha meiega koostööd!

Tehke ekskursioon meie VR-tehases:

Tehke ekskursioon meie VR-tehases koos järgmisega

Hüdrosilindri kasutamine: