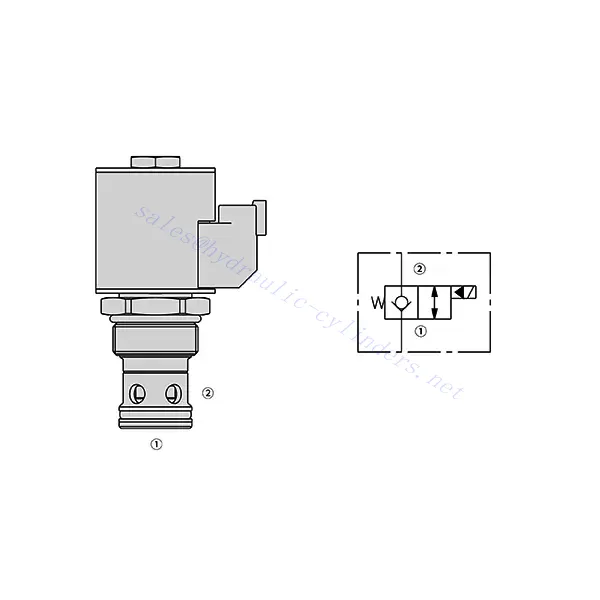

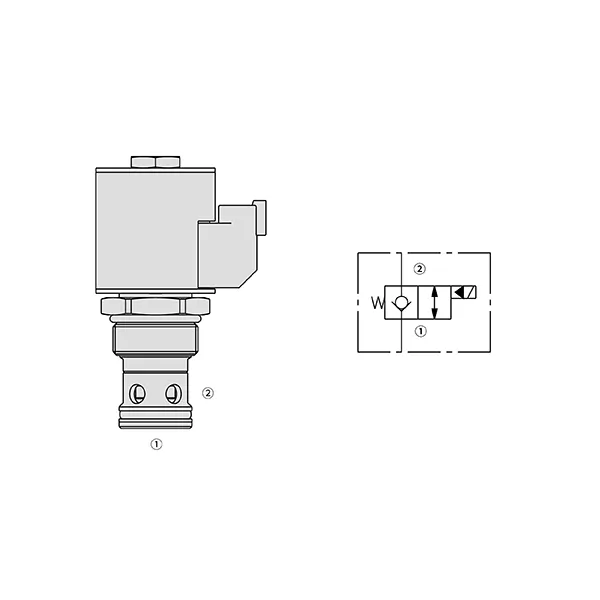

30SD16-22 Solenoid Directional Valve

Üheks hüdrosilindrite tootjaks, tarnijaks ja mehaaniliste toodete eksportijaks pakume hüdrosilindreid ja paljusid teisi tooteid.

Palun võtke meiega ühendust üksikasjade saamiseks.

Post:sales@hydraulic-cylinders.net

Tootja tarnija eksportija hüdrosilindrid.

30SD16-22 Solenoid Directional Valve

The 30SD16-22 Solenoid Directional Valve is a versatile and reliable component used in fluid control systems. With its advanced design and high-quality construction, this valve offers precise control over fluid flow, making it suitable for various industrial applications.

The 30SD16-22 Solenoid Directional Valve is an essential component for precise fluid control in industrial applications. Its robust construction, efficient performance, and versatility make it an ideal choice for a wide range of fluid control systems. Proper maintenance will ensure its optimal functionality and longevity. Invest in the 30SD16-22 Solenoid Directional Valve to enhance your fluid control operations and achieve exceptional results.

30SD16-22 Solenoid Directional Valve Characteristics:

- Robust Construction: The 30SD16-22 Solenoid Directional Valve is built with durable materials, ensuring longevity and resistance to wear and corrosion even in demanding environments.

- Efficient Performance: With its solenoid operation, this valve offers rapid response times, enabling quick adjustments to fluid flow and pressure for optimal performance.

- Compact Design: The valve’s compact size allows for easy installation in space-constrained areas or systems that require multiple valves in close proximity.

- Versatile Mounting Options: The 30SD16-22 Solenoid Directional Valve offers flexible mounting options such as inline, manifold, or subplate, facilitating seamless integration into various fluid control systems.

30SD16-22 Solenoid Directional Valve Parameter:

| Rated pressure | 207 bar(3000 psi) | |

| Peak flow | See performance chart | |

| Internal Leakage | ≤3 drops/min@207bar | |

| Coil Duty Rating | Continuous from 85% to 115% of nominal voltage | |

| Initial Coil Current Draw at 20℃ | E-coil | 1.7A at 12VDC; 0.85A at 24VDC |

| D-coil | 1.67A at 12VDC; 0.83A at 24VDC | |

| Minimum pull-in voltage | 85% of nominal at 207 bar (3000 psi) | |

| Cavity | VC16-2 (See technical reference) | |

| Fluid | Mineral-based or synthetics with lubricating properties | |

| Fluid temperature range ℃ | -54 to 107 ℃ (Polyurethane seals) | |

| -40 to 100 ℃ (Buna N seals) | ||

| -26 to 204 ℃ (Fluorocarbon seals) | ||

| Viscosity range | 7.4 to 420 mm2/s | |

| Degree of contamination | The minimum pollution level is ISO4406 level 20/18/14, and level 17/15/13 is recommended to prolong the service life | |

30SD16-22 Solenoid Directional Valve Advantages:

• Continuous-duty rated coil

• Cartridges are voltage interchangeable

• Optional waterproof E-Coils rated up to IP69K

• Efficient wet-armature construction

• Industry common cavity

• Hardened parts for long life

Usage Method Of 30SD16-22 Solenoid Directional Valve:

- Fluid Control: This valve provides precise control over fluid flow, allowing users to regulate the speed, direction, and pressure of fluids in hydraulic, pneumatic, or other fluid systems.

- Cylinder Actuation: The 30SD16-22 Solenoid Directional Valve is commonly used to actuate cylinders in industrial machinery, enabling precise movement and positioning.

- Process Automation: It plays a crucial role in automated processes by controlling fluid flow to different parts of the system based on specific operational requirements.

- Safety Applications: This valve can be employed as a safety measure, providing emergency shutdown capabilities in critical situations to prevent damage or accidents.

How To Replace A Moen Shower Mixing Valve Cartridge?

Replacing a Delta shower valve cartridge is a straightforward process that can be completed with a few basic tools. Here’s a step-by-step guide on how to replace a Delta shower valve cartridge:

- Gather the necessary tools: You will need an adjustable wrench, a screwdriver (Phillips or flathead, depending on your specific shower valve), a cartridge removal tool (included in some replacement cartridge kits), and a new Delta shower valve cartridge.

- Turn off the water supply: Locate the main water shut-off valve for your home and turn it off to ensure no water flows to the shower. If you have a dedicated shut-off valve for the shower, you can use that instead.

- Remove the handle and trim: Depending on the type of handle, you may need to unscrew it or pry off a decorative cap to access the screw holding it in place. Use a screwdriver to remove the screw and gently pull off the handle. Next, remove any trim or decorative coverings around the valve, exposing the cartridge.

- Remove the old cartridge: Look for a retaining clip or nut securing the cartridge in place. Use pliers or an adjustable wrench to loosen and remove the clip or nut. Once it’s removed, you can pull out the old cartridge. If it’s stuck, you can use a cartridge removal tool to assist in pulling it out.

- Install the new cartridge: Take the new Delta shower valve cartridge and align it with the valve body. Ensure that any alignment tabs or notches match up correctly. Gently push the cartridge into place until it sits flush with the valve body.

- Reassemble the valve: Replace the retaining clip or nut to secure the new cartridge in place. Double-check that it’s firmly in position.

- Test for leaks: Slowly turn on the water supply, and check for any leaks around the valve. If you notice any leaks, tighten the cartridge or connections as needed.

- Reinstall the trim and handle: Put back the trim or decorative coverings over the valve. Slide the handle back onto the cartridge stem and secure it with the retaining screw. If applicable, reattach any decorative cap or cover.

- Turn on the water supply: Once everything is securely reinstalled, turn on the water supply and check for proper functioning. Test the hot and cold water settings to ensure they’re working correctly.

Tehase võimekus ja suutlikkus:

(1) Kokkupanek

Meil on esmaklassiline sõltumatu teadus- ja arendustegevuse montaažiplatvorm. Hüdrosilindrite tootmistöökojas on neli poolautomaatset tõstesilindrite koosteliini ja üks automaatne kallutussilindrite koosteliin, mille kavandatud aastane tootmisvõimsus on 1 miljon tükki. Spetsiaalsete silindrite töökoda on varustatud erinevate spetsifikatsioonidega poolautomaatse puhastusmontaažisüsteemiga, mille kavandatud aastane tootmisvõimsus on 200 000 ja mis on varustatud kuulsate CNC-töötlemisseadmete, mehaanilise töötlemise keskuse, suure täpsusega silindrite töötlemise eriseadmete, robotkeevitusmasina, automaatse puhastusmasina, automaatse silindri kokkupanemise masina ja automaatse värvimise tootmisliiniga. Olemasolevad kriitilised seadmed rohkem kui 300 komplekti (komplekti). Seadmete ressursside optimaalne jaotamine ja tõhus kasutamine tagavad toodete täpsusnõuded ja vastavad toodete kvaliteedinõuetele.

(2) Töötlemine

Töödeldav töökoda on varustatud kohandatud kallutatud rööpse treipingi keskuse, mehaanilise keskuse, kiire lihvimismasina, keevitusroboti ja muude seotud seadmetega, mis suudavad töödelda silindritorusid, mille maksimaalne siseläbimõõt on 400 mm ja maksimaalne pikkus on 6 meetrit.

(3) Keevitamine

(4) Värvimine ja katmine

Väikese ja keskmise suurusega silindri automaatse veepõhise värvipinnakattega liinide abil, et saavutada automaatne robotlaadimine ja mahalaadimine ning automaatne pihustamine, projekteerimisvõimsus 4000 tükki vahetuse kohta;

Meil on ka poolautomaatne suurte balloonide värvimise tootmisliin, mis töötab jõukettaga ja mille projekteerimisvõimsus on 60 kasti ühe vahetuse kohta.

(5) Testimine

Meil on esmaklassilised kontrolliseadmed ja katsestendid, et tagada silindri jõudlus vastavus nõuetele.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding põllumajanduslikud käigukastid. Oleme eksportinud oma tooteid klientidele üle maailma ja teeninud hea maine tänu meie suurepärasele tootekvaliteedile ja müügijärgsele teenindusele. Me tervitame kliente kodus ja välismaal, et võtta meiega ühendust, et pidada läbirääkimisi äri, vahetada teavet ja teha meiega koostööd!

Tehke ekskursioon meie VR-tehases:

Tehke ekskursioon meie VR-tehases koos järgmisega

Hüdrosilindri kasutamine: