Aerial Work Platform Outrigger Cylinder

Üheks hüdrosilindrite tootjaks, tarnijaks ja mehaaniliste toodete eksportijaks pakume hüdrosilindreid ja paljusid teisi tooteid.

Palun võtke meiega ühendust üksikasjade saamiseks.

Post:sales@hydraulic-cylinders.net

Tootja tarnija eksportija hüdrosilindrid.

Aerial Work Platform Outrigger Cylinder

The aerial work platform outrigger cylinder is a vital component designed to enhance stability and safety in aerial work platforms. This specialized hydraulic cylinder plays a crucial role in extending and retracting the outriggers, which provide additional support and balance to the forum.

The aerial work platform outrigger cylinder is indispensable for ensuring stability and safety in elevated work environments. With its robust construction, reliable stability, smooth operation, and versatile adjustability, this hydraulic cylinder is crucial in extending and retracting the outriggers, providing a secure and level working platform. By following the recommended usage methods and maintenance practices, operators can maximize the longevity and performance of the aerial work platform outrigger cylinder, contributing to enhanced productivity, safety, and confidence in various elevated work applications. Invest in this essential hydraulic component to elevate your aerial work platform’s stability and unlock new levels of efficiency and safety in elevated work scenarios.

Aerial Work Platform Outrigger Cylinder Key Characteristics:

- Vastupidav konstruktsioon:

- The aerial work platform outrigger cylinder is built with high-quality materials, ensuring durability and longevity.

- It is designed to withstand heavy loads and the rigors of demanding work environments.

- Reliable Stability:

- This cylinder provides reliable stability by extending the outriggers, significantly increasing the platform’s footprint and preventing tipping or tilting during operation.

- It enhances the overall stability of the aerial work platform, allowing operators to perform tasks safely and securely at elevated heights.

- Sujuv toimimine:

- The hydraulic system of the aerial work platform outrigger cylinder ensures smooth and controlled extension and retraction of the outriggers.

- It enables operators to position the outriggers precisely, adapting to uneven surfaces and providing a level working platform.

- Versatile Adjustability:

- The outrigger cylinder offers adjustable extension lengths, allowing operators to adapt to various worksite conditions and space limitations.

- It provides flexibility in positioning the outriggers to ensure maximum stability and balance on different terrains.

Aerial Work Platform Outrigger Cylinder Parameter:

| Product Name | Aerial Work Platform Outrigger Cylinder |

| Features: | Support the weight of the entire equipment when the crane is lifting |

| Bore diameter: | 45mm~200mm |

| Rod diameter: | 30mm~180mm Stroke≤2000mm |

| Pressure: | 30MPa(Maximum pressure) |

| Outrigger Cylinder Applications: | Aerial Work Platform |

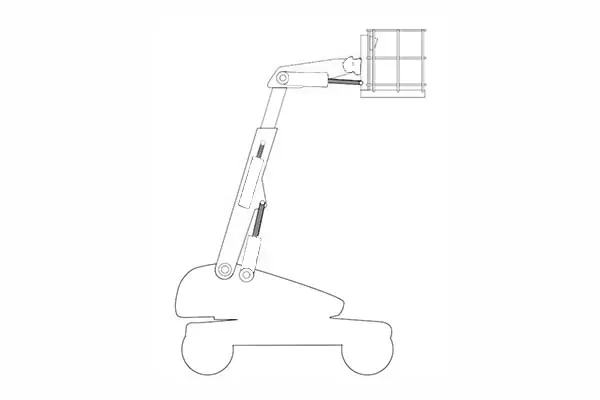

Aerial Work Platform Identification Diagram:

Usage Method Of Aerial Work Platform Outrigger Cylinder:

- Installation and Setup:

- Follow the manufacturer’s instructions to install and set up the aerial work platform outrigger cylinder on the aerial work platform.

- Ensure that the cylinder is securely mounted and aligned for optimal performance.

- Hydraulic Connection:

- Connect the outrigger cylinder to the hydraulic system of the aerial work platform according to the provided guidelines.

- Ensure that all hydraulic connections are secure and properly sealed to prevent leaks or loss of hydraulic fluid.

- Outrigger Operation:

- Engage the control mechanisms on the aerial work platform to extend or retract the outriggers.

- Follow the recommended procedures and safety guidelines during the outrigger operation.

- Positioning and Adjustment:

- Position the outriggers to provide maximum stability and support to the aerial work platform.

- Adjust the extension lengths of the outriggers as required to accommodate different worksite conditions and achieve a level platform.

How To Release Pressure On Hydraulic System?

Releasing pressure from a hydraulic system is essential for maintenance, repairs, or when working with hydraulic components. Here are some general steps to safely remove stress from a hydraulic system:

- Identify the Power Source:

- Locate the power source that supplies pressure to the hydraulic system. This is typically a hydraulic pump or an engine-driven power unit.

- Identify the power supply and ensure it is turned off or the engine is shut down to prevent accidental activation.

- Engage Control Levers:

- Move any control levers or switches to their neutral or off positions. This helps prevent unintended movement of hydraulic components and reduces the risk of pressure buildup.

- Relieve Pressure at the Control Valve:

- Locate the control valve or pressure relief valve in the hydraulic system. It is usually marked or labeled for easy identification.

- Slowly turn or adjust the valve to its release or open position. This allows trapped hydraulic fluid to escape and reduces pressure in the system.

- It is essential to release pressure gradually to avoid sudden movements or fluid discharge.

- Monitor Pressure Gauge:

- Some hydraulic systems may have pressure gauges installed. If available, monitor the pressure gauge while releasing pressure.

- As you open the control valve, observe the pressure gauge to ensure the pressure is decreasing steadily.

- Bleed Hydraulic Components:

- After relieving pressure at the control valve, it is advisable to bleed the hydraulic components that may still hold residual pressure.

- Start by loosening or removing any fittings or connections downstream of the control valve.

- Slowly and carefully open the fittings to allow any remaining pressure to escape.

- Use caution as hydraulic fluid may be under pressure and can spray or leak out.

- Verify Pressure Release:

- Double-check that pressure has been effectively released from the system by confirming the pressure gauge reads zero or close to zero.

- Inspect the hydraulic components to ensure no movement or signs of pressure remaining.

Tehase võimekus ja suutlikkus:

(1) Kokkupanek

Meil on esmaklassiline sõltumatu teadus- ja arendustegevuse montaažiplatvorm. Hüdrosilindrite tootmistöökojas on neli poolautomaatset tõstesilindrite koosteliini ja üks automaatne kallutussilindrite koosteliin, mille kavandatud aastane tootmisvõimsus on 1 miljon tükki. Spetsiaalsete silindrite töökoda on varustatud erinevate spetsifikatsioonidega poolautomaatse puhastusmontaažisüsteemiga, mille kavandatud aastane tootmisvõimsus on 200 000 ja mis on varustatud kuulsate CNC-töötlemisseadmete, mehaanilise töötlemise keskuse, suure täpsusega silindrite töötlemise eriseadmete, robotkeevitusmasina, automaatse puhastusmasina, automaatse silindri kokkupanemise masina ja automaatse värvimise tootmisliiniga. Olemasolevad kriitilised seadmed rohkem kui 300 komplekti (komplekti). Seadmete ressursside optimaalne jaotamine ja tõhus kasutamine tagavad toodete täpsusnõuded ja vastavad toodete kvaliteedinõuetele.

(2) Töötlemine

Töödeldav töökoda on varustatud kohandatud kallutatud rööpse treipingi keskuse, mehaanilise keskuse, kiire lihvimismasina, keevitusroboti ja muude seotud seadmetega, mis suudavad töödelda silindritorusid, mille maksimaalne siseläbimõõt on 400 mm ja maksimaalne pikkus on 6 meetrit.

(3) Keevitamine

(4) Värvimine ja katmine

Väikese ja keskmise suurusega silindri automaatse veepõhise värvipinnakattega liinide abil, et saavutada automaatne robotlaadimine ja mahalaadimine ning automaatne pihustamine, projekteerimisvõimsus 4000 tükki vahetuse kohta;

Meil on ka poolautomaatne suurte balloonide värvimise tootmisliin, mis töötab jõukettaga ja mille projekteerimisvõimsus on 60 kasti ühe vahetuse kohta.

(5) Testimine

Meil on esmaklassilised kontrolliseadmed ja katsestendid, et tagada silindri jõudlus vastavus nõuetele.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding põllumajanduslikud käigukastid. Oleme eksportinud oma tooteid klientidele üle maailma ja teeninud hea maine tänu meie suurepärasele tootekvaliteedile ja müügijärgsele teenindusele. Me tervitame kliente kodus ja välismaal, et võtta meiega ühendust, et pidada läbirääkimisi äri, vahetada teavet ja teha meiega koostööd!

Tehke ekskursioon meie VR-tehases:

Tehke ekskursioon meie VR-tehases koos järgmisega

Hüdrosilindri kasutamine: