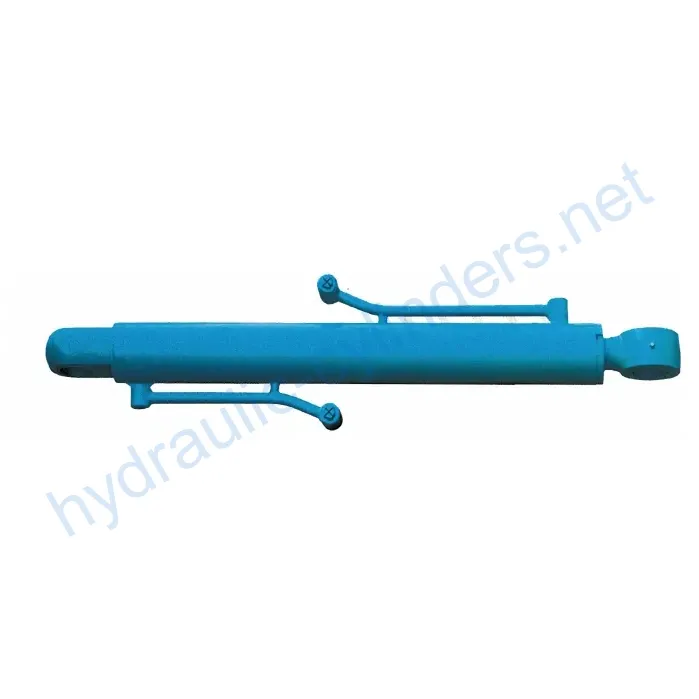

Bucket Cylinder For World Small Excavator W285B-8

Üheks hüdrosilindrite tootjaks, tarnijaks ja mehaaniliste toodete eksportijaks pakume hüdrosilindreid ja paljusid teisi tooteid.

Palun võtke meiega ühendust üksikasjade saamiseks.

Post:sales@hydraulic-cylinders.net

Tootja tarnija eksportija hüdrosilindrid.

Bucket Cylinder For World Small Excavator W285B-8

Introduction

A bucket cylinder is a specially designed hydraulic cylinder used to control the movement of buckets in heavy machinery such as excavators, backhoe excavators, and front-end loaders. Its main function is to enable the bucket to lift, lower, and tilt, thus facilitating various material handling tasks. In the hydraulic system, the bucket cylinder uses the pressure change of hydraulic oil to achieve precise control of the bucket, enabling the operator to handle heavy loads efficiently, adapt to complex work environments and diverse operational needs.

Features

- High strength and durability: Usually made of high-strength steel or aluminum, it can withstand high pressure and heavy loads, adapt to harsh working environments, and is designed with wear resistance and corrosion resistance to extend service life.

- Efficient hydraulic operation: Smooth extension and contraction actions are achieved by utilizing hydraulic oil pressure, which can quickly respond to control commands, provide powerful pushing and pulling forces, and is suitable for handling heavy loads and complex operational tasks.

- Various types: Single-acting (hydraulic only in one direction) or double-acting (hydraulic in both directions) cylinders can be selected according to operational needs. Some models are telescopic, allowing for greater extension without increasing external dimensions, making them suitable for applications with limited space.

- Production capability: Our products can perfectly replace these hydraulic cylinders.

Applications

The bucket cylinder is widely used in various industries, such as construction equipment, agricultural machinery, excavators, and loaders. It is mainly used for lifting, lowering, tilting, and other tasks.

Construction equipment

In excavators, they are essential for digging, loading, and moving soil or debris. In backhoe excavators, the bucket cylinder helps with both digging and lifting. In front-end loaders, they assist in efficient lifting and dumping of goods.

Agricultural machinery

The bucket cylinder is used for front-end loaders and is essential for lifting and tilting soil, hay, and other materials.

Excavators

The bucket cylinder allows the bucket to penetrate the soil to perform digging actions.

Loaders

In front loaders, they help with lifting and tilting goods effectively.

Design Considerations and Selection Criteria

The selection of bucket cylinder design and materials is critical to ensuring optimal performance and durability. Key considerations include load-bearing capacity, sealing, durability, safety, and maintainability.

Load-bearing capacity

Bucket cylinders are subjected to extreme loads, so it is essential to choose materials, thickness, and design that can withstand these forces. High-strength steel or aluminum is commonly used in the production of bucket cylinders to provide the necessary strength.

Sealing

The bucket cylinder is an essential component of the hydraulic system, and proper sealing is critical to its efficient operation. Various seals, such as piston seals and rod seals, are used to ensure the hydraulic fluid remains contained within the cylinder and prevent contaminants from entering the system.

Durability

The bucket cylinder is exposed to harsh environments, and its materials must withstand wear and corrosion. Cylinders are made of high-strength materials that are designed to withstand these harsh conditions, and the cylinder’s surface is treated to provide additional wear resistance.

Safety

Bucket cylinders are subjected to extreme loads, and it is essential to ensure they are safe to operate. Design considerations such as safety valves, emergency stop switches, and pressure relief valves are used to ensure the system operates safely and prevent damage to the cylinder.

Maintainability

Bucket cylinders require regular maintenance to ensure optimal performance and extend service life. The use of easily replaceable seals, external access to critical components, and proper lubrication are critical to ensuring maintainability.

Seals and Lubrication

The proper selection of seals and lubrication is critical to ensuring optimal performance and extending service life. Various seals such as piston seals, rod seals, and wipers are used to prevent fluid leakage and ensure efficient operation. The use of lubricants such as hydraulic oil is critical to reducing friction and wear and maintaining efficient operation. Regular maintenance is essential to ensure proper lubrication levels and prevent wear and tear on critical components.

Maintenance and Repair

Regular maintenance and repair of the bucket cylinder are essential to ensuring optimal performance and extending service life. Common maintenance tasks include regular checks, proper lubrication, seal replacement, and calibration checks. Proper installation is also critical to ensuring optimal performance, and proper alignment and use of installation brackets are recommended. To ensure optimal performance and extend service life, it is recommended to replace components as needed and utilize rebuild services.

Safety and Environmental Considerations

When using bucket cylinders, it is essential to follow proper safety procedures and guidelines to ensure optimal performance and prevent accidents. Safety considerations such as wearing proper protective equipment, proper installation, and operation, and following proper maintenance schedules are critical to ensuring safe operation. Environmental considerations such as proper disposal of used hydraulic oil and components are also essential to reducing environmental impact and ensuring compliance with regulations.

Fault Diagnosis and Troubleshooting

Common problems with bucket cylinders can include leaks, loss of power, and reduced performance. Proper diagnosis and troubleshooting are critical to identifying the root cause of these issues and developing effective solutions. Common troubleshooting steps include checking for leaks, checking fluid levels, and inspecting critical components. Proper preventive measures, such as regular maintenance and inspection, can help reduce the likelihood of these issues and ensure optimal performance.

About Our Company

We are a leading manufacturer and distributor of hydraulic cylinders, specializing in replacement cylinders. Our company adheres to the principle of excellent quality, relying on industrial production management strategies, and technological talent, digital high-end manufacturing equipment, and professional testing systems to continuously improve the manufacturing platform and perfect product quality production lines. Our products have high efficiency, high precision, and high quality, meeting the diverse needs of our customers both domestically and internationally.

Professionalism

We have a team of professionals who are highly knowledgeable in the field of hydraulic cylinders and can provide expert advice on product selection, installation, and maintenance.

International Certification

Our products have received various international certifications, ensuring they meet the highest industry standards.

Customization

We offer customization services to meet the specific requirements of our customers and ensure optimal performance.

Production Equipment

Our production equipment is of the highest quality and designed to produce hydraulic cylinders that meet the highest industry standards.

After-sales Service

We offer comprehensive after-sales service to ensure our customers are satisfied with their purchases and receive the support they need.

Author: lyl.

Tehke ekskursioon meie VR-tehases:

Tehke ekskursioon meie VR-tehases koos järgmisega

Hüdrosilindri kasutamine: