Replacement Of A45308 Hydraulic Cylinder End

Üheks hüdrosilindrite tootjaks, tarnijaks ja mehaaniliste toodete eksportijaks pakume hüdrosilindreid ja paljusid teisi tooteid.

Palun võtke meiega ühendust üksikasjade saamiseks.

Post:sales@hydraulic-cylinders.net

Tootja tarnija eksportija hüdrosilindrid.

Replacement Of A45308 Hydraulic Cylinder End

Introduction

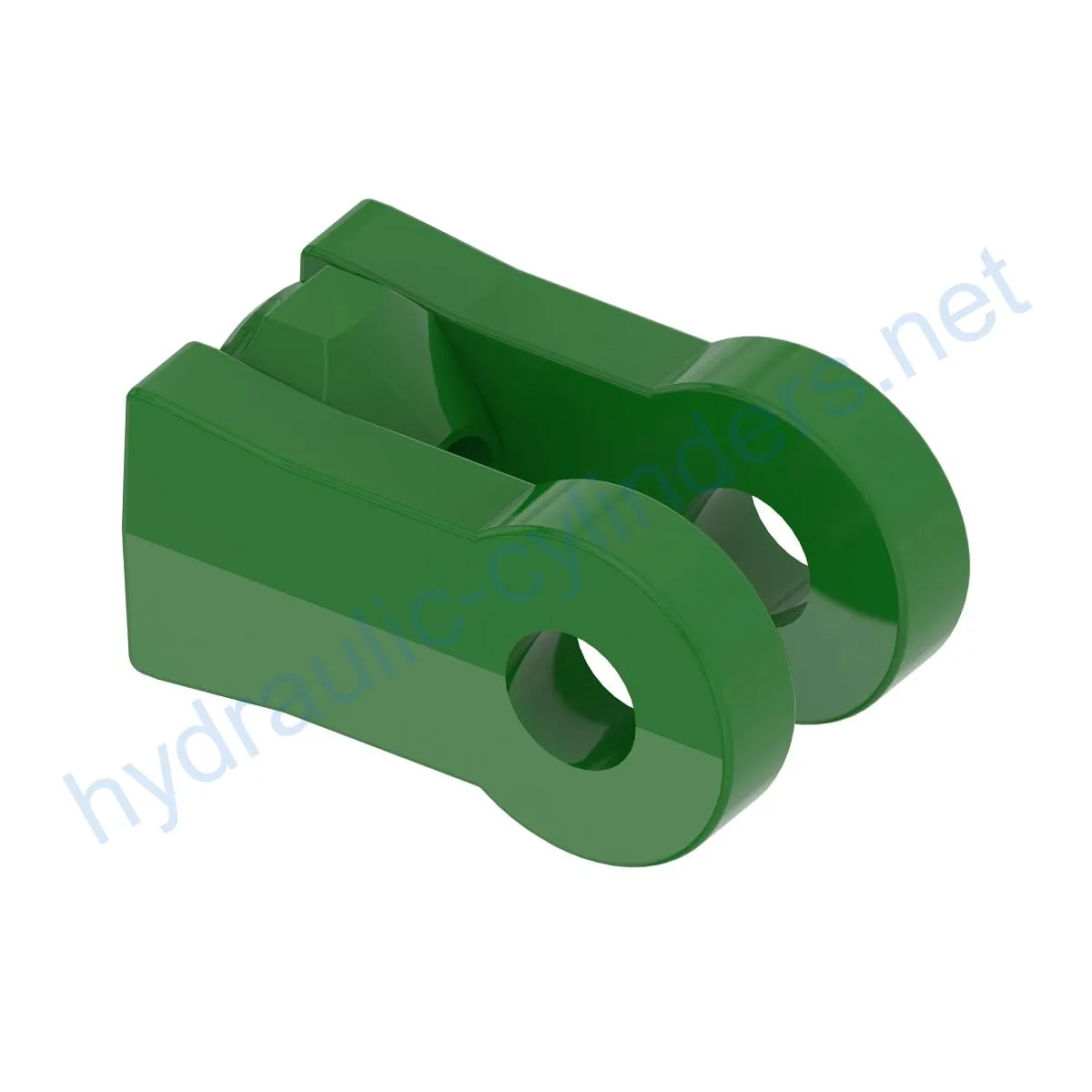

The Replacement Of A45308 Hydraulic Cylinder End is a high-quality hydraulic cylinder designed to replace damaged or worn-out cylinders. It plays a crucial role in various applications by restoring the normal operation of equipment. With a weight of 5.51 lb, a height of 2.5 in, a width of 2.6 in, a length of 4.6 in, and a screw size of 1.062 in, this cylinder is versatile and compatible with multiple models, including 610, 637, 650, 680, 726, 735, 970, 980, 1700, 1710, 1720, 1730, 1810, 1820, and 2400.

Specifications

- Weight: 5.51 lb

- Height: 2.5 in

- Width: 2.6 in

- Length: 4.6 in

- Screw Size: 1.062 in

Features

- Improved Equipment Performance: Replacing damaged or worn-out hydraulic cylinders can restore the normal operating capability of equipment, ensuring optimal performance in various applications.

- Enhanced Safety: Regularly replacing hydraulic cylinders reduces safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

- Overload Protection: Newly designed cylinders often incorporate better overload protection mechanisms, improving overall safety.

- Quick Installation: Modern hydraulic cylinders are designed for easy installation and replacement, minimizing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it convenient to obtain replacement parts in the market.

Applications

- Excavators: The hydraulic cylinder in excavator arms or buckets may get damaged due to prolonged use or overload, requiring replacement to restore normal operation.

- Cranes: The hydraulic cylinder in crane boom arms is susceptible to wear and tear during frequent lifting and lowering processes, necessitating regular replacement for safety purposes.

- Tractors: The hydraulic cylinder in front-end loader attachments of tractors may develop leaks or experience performance degradation during continuous lifting and tilting operations, requiring replacement.

- Harvesters: The hydraulic system in harvesters operates under high pressure, and cylinders may get damaged due to fatigue, requiring timely replacement to maintain work efficiency.

- Automated Production Lines: Hydraulic cylinders are used to control robotic arms and other automated equipment. Cylinder failure can significantly impact production efficiency, necessitating immediate replacement.

- Die Casting Machines: In high-pressure and high-temperature environments, hydraulic cylinders may experience performance degradation. Regular replacement ensures product quality.

- Mining Equipment: Hydraulic cylinders are used for lifting and moving heavy loads in mining equipment. Due to harsh working conditions, regular inspection and replacement are necessary to avoid equipment failure.

- Bulldozers: The hydraulic cylinder in bulldozer blade arms may experience wear, resulting in a decrease in pushing capacity. Timely replacement is essential to maintain operational efficiency.

Maintenance Tasks

Regular maintenance tasks for the Replacement Of A45308 Hydraulic Cylinder End include:

- Periodic Inspections

- Proper Lubrication

- Seal Replacement

- Calibration Checks

Safety Considerations and Environmental Factors

When using hydraulic cylinders, it is crucial to prioritize safety measures to prevent accidents and minimize environmental impact. Ensuring proper installation, lubrication, and adjustment is essential. Providing guidance on aligning the cylinder correctly during installation and recommending the use of appropriate mounting brackets for stability can enhance safety. Additionally, suggesting inspection, repair, and replacement procedures, as well as offering parts replacement and rebuilding services, can increase the lifespan of the hydraulic cylinder.

Troubleshooting and Common Issues

For troubleshooting and addressing common problems related to the Replacement Of A45308 Hydraulic Cylinder End, consider the following:

- Problem: Leakage

- Solution: Check and replace faulty seals

- Problem: Poor Performance

- Solution: Inspect and replace worn-out components

- Problem: Cylinder Not Extending or Retracting

- Solution: Check for blockages, damaged seals, or insufficient hydraulic pressure

- Problem: Abnormal Noises

- Solution: Inspect for loose connections or damaged internal components

Preventive Measures

To minimize potential issues, consider the following preventive measures:

- Perform regular maintenance inspections

- Ensure proper lubrication

- Replace seals as needed

- Conduct calibration checks

Design Considerations and Selection Criteria

When selecting the Replacement Of A45308 Hydraulic Cylinder End, it is vital to consider the following design aspects: load-bearing capacity, sealing efficiency, durability, safety features, and ease of maintenance. Each point plays a crucial role in ensuring optimal performance and longevity.

Sealing and Lubrication

The Replacement Of A45308 Hydraulic Cylinder End incorporates various sealing components, such as piston seals and rod seals, made of wear-resistant materials like polyurethane and nitrile rubber. The cylinder’s body and threaded ends undergo meticulous surface treatment to enhance wear resistance. Regular lubrication with suitable hydraulic oil is necessary to ensure smooth operation.

Regular Inspection and Preventive Maintenance

Regular inspection and preventive maintenance are essential for maintaining the performance and longevity of the Replacement Of A45308 Hydraulic Cylinder End. Proper installation, lubrication, and adjustment are crucial. Providing guidance on aligning the cylinder correctly during installation, recommending the use of appropriate mounting brackets for stability, and suggesting inspection, repair, and replacement procedures can extend the life of the cylinder.

Installation Guidelines

Follow these guidelines for the correct installation of the

Tehke ekskursioon meie VR-tehases:

Tehke ekskursioon meie VR-tehases koos järgmisega

Hüdrosilindri kasutamine: