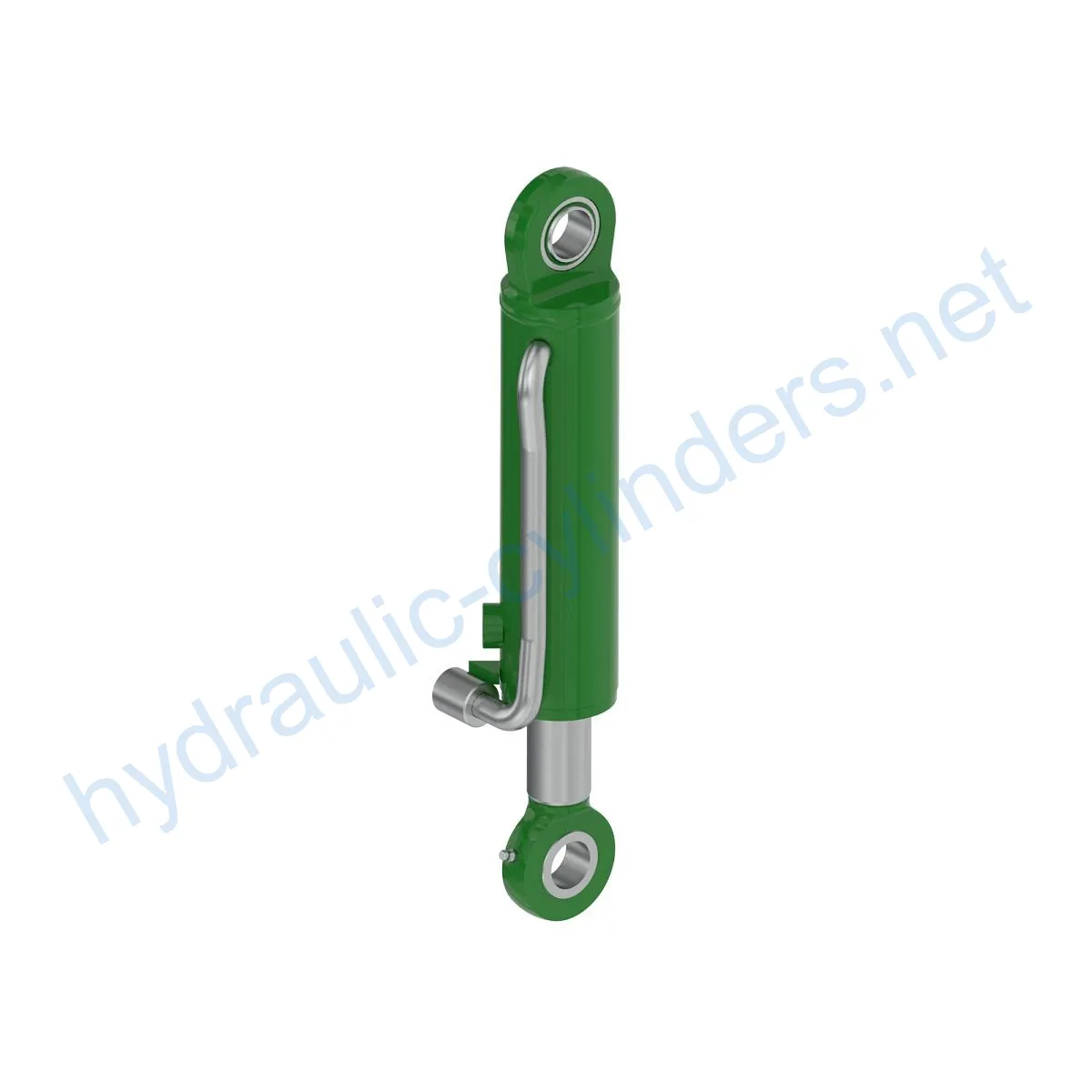

Replacement Of AL172369 Hydraulic Cylinder

Üheks hüdrosilindrite tootjaks, tarnijaks ja mehaaniliste toodete eksportijaks pakume hüdrosilindreid ja paljusid teisi tooteid.

Palun võtke meiega ühendust üksikasjade saamiseks.

Post:sales@hydraulic-cylinders.net

Tootja tarnija eksportija hüdrosilindrid.

Product Description

The Replacement Of AL172369 Hydraulic Cylinder is a hydraulic cylinder used in machines such as 6170R, 6190R, 6210R, 6930, 7430E, and 7530E. It weighs 17.52 lb with dimensions of 4.3 in height, 4.8 in width, and 17.1 in length. This hydraulic cylinder is used to power certain parts of the machine and help them perform their respective functions.

Specifications and Machine Models

The Replacement Of AL172369 Hydraulic Cylinder is compatible with machine models 6170R, 6190R, 6210R, 6930, 7430E, and 7530E. It weighs 17.52 lb with dimensions of 4.3 in height, 4.8 in width, and 17.1 in length. These specifications ensure the hydraulic cylinder fits perfectly with the machine models mentioned above.

Features

- Improves Equipment Performance: Replacing damaged or worn-out hydraulic cylinders restores the equipment’s performance in various applications.

- Enhanced Safety: Regular replacement of hydraulic cylinders helps to reduce safety hazards caused by cylinder failure, ensuring the safety of personnel and equipment.

- Overload Protection: New cylinder designs typically consider better overload protection mechanisms, enhancing safety.

- Quick Installation: Modern hydraulic cylinder designs are usually easy to install and replace, reducing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it easy to obtain replacement parts in the market.

We can manufacture this product and our product can perfectly replace these hydraulic cylinders.

Applications

The Replacement Of AL172369 Hydraulic Cylinder can be used in various machines and equipment. Here are a few examples:

Excavators

In excavators, the hydraulic cylinder may become damaged due to long-term use or overload on the arm or bucket. Replacing it is necessary to restore normal operation.

Cranes

The crane’s boom hydraulic cylinder is subject to frequent lifting and lowering, leading to wear and tear. Regular replacement is necessary to ensure safety.

Tractors

The front-end loader hydraulic cylinder in tractors can leak or experience performance degradation due to continuous lifting and tilting operations, thus requiring replacement.

Harvesters

During the harvesting process, the hydraulic system experiences high pressure, and cylinders may become damaged due to fatigue. Timely replacement is necessary to maintain work efficiency.

Automated Production Lines

Hydraulic cylinders are used in controlling robotic arms and other automated equipment. Cylinder failure can affect production efficiency and requires immediate replacement.

Die Casting Machines

Hydraulic cylinders in die casting machines may experience performance degradation in high-pressure and high-temperature environments. Regular replacement ensures product quality.

Mining Equipment

Hydraulic cylinders are used in mining equipment for lifting and moving heavy objects. Due to the harsh working environment, regular inspection and replacement are necessary to avoid equipment failure.

Bulldozers

The wear of the hydraulic cylinder on the bulldozer’s pushing arm will reduce its pushing capacity, so it needs to be replaced promptly to maintain work efficiency.

Maintenance Tasks

Regular maintenance tasks for hydraulic cylinders include:

Inspection

Regular inspection ensures the hydraulic cylinder is in good condition and prevents any sudden failures.

Lubrication

Proper lubrication helps reduce wear and tear on the hydraulic cylinder and extends its service life.

Seal Replacement

Replacing seals helps prevent leaks and ensures the hydraulic cylinder’s efficient operation.

Safety Considerations and Environmental Factors

Safety precautions are vital when handling hydraulic cylinders. Proper use of safety equipment and following safety procedures can prevent injuries. Environmental factors such as temperature and humidity can affect the hydraulic cylinder’s performance and should be considered during operation.

Failure Diagnosis and Troubleshooting

Common problems with hydraulic cylinders include oil leaks, sluggish operation, and abnormal noise. Proper diagnosis and troubleshooting can help identify the root cause of these problems and lead to effective solutions.

Design Considerations and Selection Criteria

When selecting a hydraulic cylinder, it is essential to consider its load-bearing capacity, sealing, durability, safety, and ease of maintenance. These factors contribute to the hydraulic cylinder’s overall performance and service life.

Sealing and Lubrication

Hydraulic cylinders use various seals such as piston seals and rod seals made of materials such as polyurethane and nitrile rubber. Regular lubrication and the use of appropriate materials help prevent leaks and extend the hydraulic cylinder’s service life.

Installation Guide

Proper installation is critical to the hydraulic cylinder’s performance and service life. Correct alignment, the use of appropriate installation brackets, and recommended inspection, repair, and replacement procedures can enhance the hydraulic cylinder’s performance.

Company Introduction

We are a manufacturer of replacement hydraulic cylinders with a complete product line, making us one of the leading manufacturers and wholesale distributors of hydraulic cylinders in the domestic and international markets. Our company offers professional services, international certifications, customized services, advanced production equipment, and excellent after-sales service.

Author: lyl

Tehke ekskursioon meie VR-tehases:

Tehke ekskursioon meie VR-tehases koos järgmisega

Hüdrosilindri kasutamine: