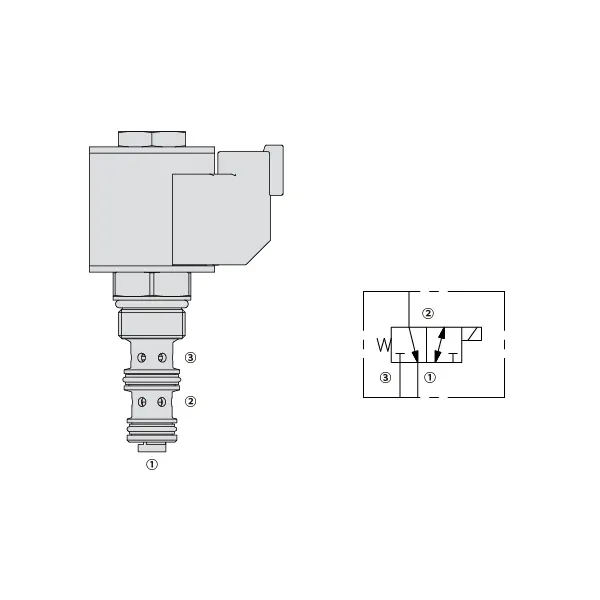

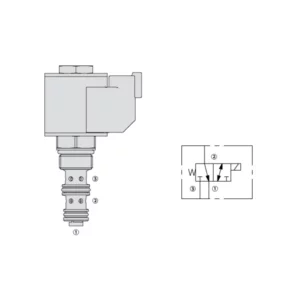

30SD08-30 Solenoid Directional Valve

Yhtenä hydraulisylinterien valmistajista, toimittajista ja mekaanisten tuotteiden viejistä tarjoamme hydraulisylintereitä ja monia muita tuotteita.

Ota yhteyttä meihin saadaksesi lisätietoja.

Posti:sales@hydraulic-cylinders.net

Valmistaja toimittaja viejä hydraulisylinterit.

30SD08-30 Solenoid Directional Valve

Experience unparalleled precision and control in your hydraulic system with the 30SD08-30 solenoid directional valve. This high-performance valve is designed to meet the demands of industrial applications, offering seamless fluid flow management and reliable operation.

The 30SD08-30 solenoid directional valve is a game-changer for hydraulic systems, offering precise control, high flow capacity, and rapid response time. With its durability and reliability, this valve guarantees optimal performance and efficiency. By following the recommended usage methods and maintenance guidelines, you can harness the full potential of the 30SD08-30 solenoid directional valve, achieving seamless control, increased productivity, and improved overall performance. Upgrade your hydraulic system today with the 30SD08-30 solenoid directional valve and experience the precision and reliability it brings to your operations.

30SD08-26 Solenoid Directional Valve Characteristics:

- Accurate Fluid Flow Control:

- The 30SD08-30 solenoid directional valve provides precise control over fluid flow, ensuring accurate and reliable operation of your hydraulic system.

- Experience seamless adjustments in flow rates, facilitating optimal performance in various industrial applications.

- High Flow Capacity:

- With its high flow capacity design, the 30SD08-30 solenoid directional valve can handle substantial fluid volumes efficiently.

- This feature enables smooth and reliable operation, even in applications that require high flow rates, ensuring optimal system performance.

- Quick Response Time:

- Equipped with advanced solenoid technology, the 30SD08-30 solenoid directional valve boasts a rapid response time.

- Experience swift and accurate adjustments in fluid flow direction, allowing for enhanced system efficiency and precise control.

- Durability and Reliability:

- Built to withstand demanding operating conditions, the 30SD08-30 solenoid directional valve features a robust construction.

- Its durable materials and reliable design minimize downtime, reduce maintenance requirements, and ensure long-lasting performance.

30SD08-25 Solenoid Directional Valve Parameter:

| Rated pressure | 207 bar(3000 psi) |

| Peak flow | See performance chart |

| Fluid | Mineral-based or synthetics with lubricating properties |

| Fluid temperature range ℃ | -54 to 107 ℃ (Polyurethane seals) |

| -40 to 100 ℃ (Buna N seals) | |

| -26 to 204 ℃ (Fluorocarbon seals) | |

| Viscosity range | 7.4 to 420 mm2/s |

| Degree of contamination | The minimum pollution level is ISO4406 level 20/18/14, and level 17/15/13 is recommended to prolong the service life |

| Internal Leakage | Port 3 (De-energized): ≤ 82 mL/min@207bar |

| Port 1 (Energized): ≤ 164 mL/min@207bar | |

| Cavity | VC08-3(Cavity variation ‘A’, see technical reference) |

| Coil Duty Rating | Continuous from 85% to 115% of nominal voltage |

| Initial Coil Current Draw at 20℃ | 1.4A at 12VDC; 0.7A at 24VDC |

| Minimum pull-in voltage | 85% of nominal at 207 bar (3000 psi) |

30SD08-25 Solenoid Directional Valve Advantages:

• Continuous-duty rated coil

• Efficient wet-armature construction

• Cartridges are voltage interchangeable

• Optional waterproof E-Coils rated up to IP69K

• Hardened parts for long life

Usage Method Of 30SD08-25 Solenoid Directional Valve:

- System Evaluation:

- Begin by assessing the specific requirements of your hydraulic system, considering flow rates, pressure levels, and system dynamics.

- Evaluate if the 30SD08-30 Solenoid Directional Valve aligns with your system’s needs, taking into account its precision, flow capacity, and compatibility with other components.

- Valve Selection:

- Select the appropriate variant of the 30SD08-30 solenoid directional valve based on your system parameters and performance requirements.

- Consider factors such as flow capacity, pressure ratings, and compatibility to ensure seamless integration and optimal functionality.

- Installation:

- Follow the manufacturer’s installation instructions carefully to ensure proper placement and secure mounting of the valve.

- Position the valve correctly within the hydraulic system, considering fluid flow direction and accessibility for maintenance purposes.

- Electrical Connections:

- Connect the solenoid valve to the designated power source according to the manufacturer’s specifications.

- Ensure that the electrical connections are secure, adhering to safety standards and guidelines.

How To Hook Up A Hydraulic Flow Control Valve?

To hook up a hydraulic flow control valve, follow these steps:

- Identify Valve Type: Determine the specific type of flow control valve you are working with. Common types include needle valves, adjustable flow control valves, or pressure-compensated flow control valves. Ensure that the valve is suitable for your application and compatible with your hydraulic system.

- Gather Required Tools and Materials: Collect the necessary tools and materials, including appropriate hydraulic fittings, adapters, hoses, and wrenches.

- Prepare the Hydraulic System: Shut down the hydraulic system and relieve any pressure in the system by activating the relief valve or retracting any hydraulic cylinders. This step is crucial for safety.

- Identify Flow Direction: Identify the flow direction in your hydraulic system. Typically, the flow direction is indicated by arrows on the hydraulic components. Ensure that you understand the correct flow direction before proceeding.

- Locate Installation Point: Determine the optimal location to install the flow control valve in your hydraulic system. Consider factors such as accessibility, proximity to the actuator or hydraulic component, and ease of adjustment.

- Mount the Valve: Securely mount the flow control valve in the chosen location using appropriate brackets or clamps. Ensure the valve is positioned correctly, aligning the inlet and outlet ports with the flow direction.

- Connect the Inlet and Outlet Ports: Attach hydraulic hoses or tubing to the inlet and outlet ports of the flow control valve. Use suitable hydraulic fittings and adapters to create a leak-free connection. Tighten the connections using wrenches to ensure a secure fit, but avoid over-tightening.

- Adjust the Flow Control: Depending on the type of flow control valve, it may have adjustable features such as a needle valve or a flow control knob. Adjust the valve according to your desired flow rate or speed. Refer to the manufacturer’s instructions for specific adjustment procedures.

- Test the System: Once the flow control valve is installed and adjusted, slowly restore hydraulic system pressure. Test the system to ensure that the flow control valve is functioning correctly. Monitor the flow rate or speed of the hydraulic actuator to verify that it is within the desired range.

- Fine-tune and Monitor: Adjust the flow control valve to achieve the desired flow rate or speed. Regularly monitor the hydraulic system for leaks, pressure inconsistencies, or unusual behavior.

Tehtaan kapasiteetti ja kapasiteetti:

(1) Kokoonpano

Meillä on ensiluokkainen riippumaton tutkimus- ja kehitystyön kokoonpanoalusta. Hydraulisylinterien tuotantopajassa on neljä puoliautomaattista nostosylinterin kokoonpanolinjaa ja yksi automaattinen kallistussylinterin kokoonpanolinja, joiden suunniteltu vuotuinen tuotantokapasiteetti on 1 miljoona kappaletta. Erikoissylinterin työpaja on varustettu erilaisilla eritelmillä puoliautomaattisen puhdistusasennuksen kokoonpanojärjestelmällä, jonka suunniteltu vuotuinen tuotantokapasiteetti on 200 000, ja se on varustettu kuuluisilla CNC-työstölaitteilla, työstökeskuksella, korkean tarkkuuden sylinterin käsittelyyn tarkoitetuilla erityislaitteilla, robottihitsauskoneella, automaattisella puhdistuslaitteella, automaattisella sylinterin kokoonpanokoneella ja automaattisella maalaustuotantolinjalla. Olemassa olevat kriittiset laitteet yli 300 sarjaa (sarjaa). Laiteresurssien optimaalinen kohdentaminen ja tehokas käyttö varmistavat tuotteiden tarkkuusvaatimukset ja täyttävät tuotteiden laatuvaatimukset.

(2) Koneistus

Työstöpaja on varustettu räätälöidyllä kaltevalla kiskosorvauskeskuksella, työstökeskuksella, suurnopeus-hiontakoneella, hitsausrobotilla ja muilla vastaavilla laitteilla, joilla voidaan käsitellä sylinteriputkia, joiden sisähalkaisija on enintään 400 mm ja enimmäispituus on 6 metriä.

(3) Hitsaus

(4) Maalaus ja pinnoitus

Pienillä ja keskisuurilla sylinterin automaattisilla vesipohjaisilla maalipinnoituslinjoilla automaattisen robotin lastaus- ja purku- ja automaattisen ruiskutuksen saavuttamiseksi, suunnittelukapasiteetti on 4000 kappaletta vuorossa;

Meillä on myös puoliautomaattinen maalauslinja suurille sylintereille, joka toimii voimaketjulla ja jonka suunnittelukapasiteetti on 60 laatikkoa työvuorossa.

(5) Testaus

Meillä on ensiluokkaiset tarkastustilat ja testialustat, joilla varmistetaan, että sylinterin suorituskyky täyttää vaatimukset.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding maatalousvaihteistot. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and tehdä yhteistyötä kanssamme!

Tutustu VR-tehtaaseemme:

Tutustu VR-tehtaaseemme seuraavalla kierroksella

Hydraulisylinteri Sovellus: