MOB Type Light Rod Hydraulic Cylinder

Yhtenä hydraulisylinterien valmistajista, toimittajista ja mekaanisten tuotteiden viejistä tarjoamme hydraulisylintereitä ja monia muita tuotteita.

Ota yhteyttä meihin saadaksesi lisätietoja.

Posti:sales@hydraulic-cylinders.net

Valmistaja toimittaja viejä hydraulisylinterit.

MOB Type Light Rod Hydraulic Cylinder

MOB light rod hydraulic cylinder is a low-cost cylinder of the exact specification because the pressure is slight, the composition of the cylinder thickness is thin, the piston rod is relatively small, the front and back covers are cast, and the low-pressure seal price is relatively low. MOB light rod hydraulic cylinder adopts a pull rod structure; The cylinder is connected to the front and rear covers with four screw rods and then secured with lock nuts. Easy maintenance: loosen the lock nut, remove the front cover, and replace the seal or other accessories.

MOB light rod hydraulic cylinders are installed and connected in a variety of ways, including flanges, single lugs, double lugs, foot seats, hinge shafts, and connection accessories on the piston rod, such as fisheye joints, type I joints, etc. This series of tie rod hydraulic cylinders can be used as double rod cylinders, that is, MOD series, and can be customized:

1) High-temperature conditions, using high-temperature seals

2) Plus travel switch

3) Can be made into a magnetic induction cylinder (cylinder with stainless steel, piston with copper material, plus magnetic induction switch)

4) Buffered

When To Use MOB Light Rod Hydraulic Cylinder:

1) Use instead of cylinder. The original system uses pneumatic but for various reasons (such as hydraulic control, the pursuit of more stable action, such as the strength of the pneumatic is not enough)

2) The system pressure is minimal, considering the economy, using an MOB standard cylinder.

MOB Type Light Rod Hydraulic Cylinder Parameter:

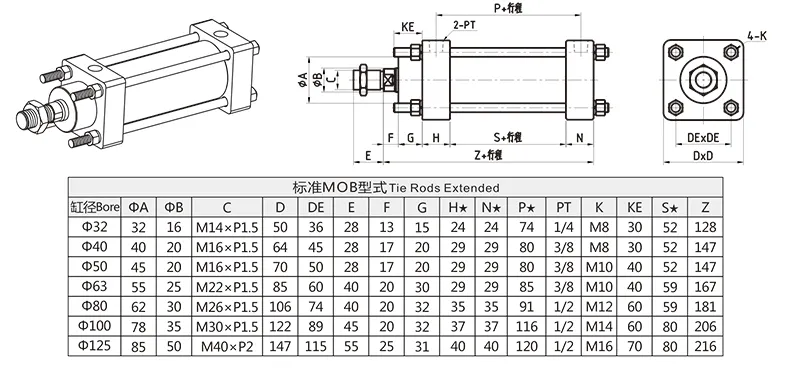

(1) Standard MOB Light Rod Hydraulic Cylinder

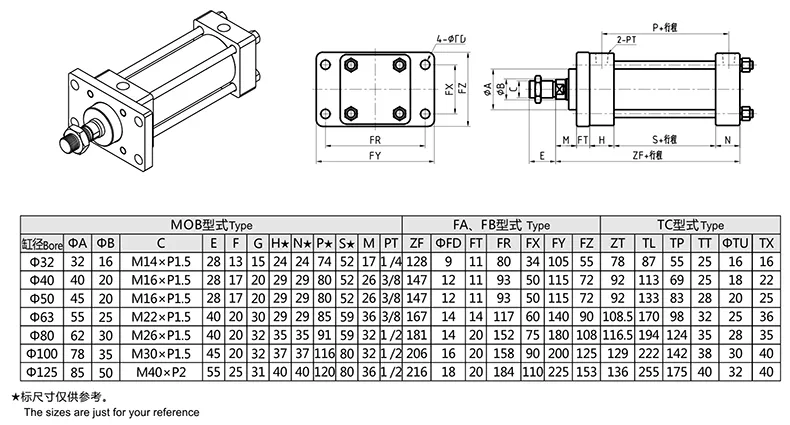

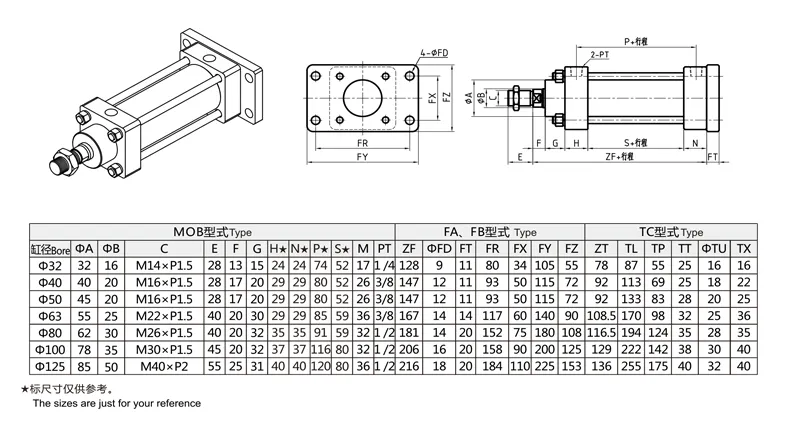

(2) FA Front Flange Type Light Rod Hydraulic Cylinder

(3) FB Rear Flange Type Light Rod Hydraulic Cylinder

(4) LB Footstand Type Light Rod Hydraulic Cylinder

(5) TC Middle Trunnion Type Light Rod Hydraulic Cylinder

(6) CA Monoaural Type Light Rod Hydraulic Cylinder

(7) CA Monoaural Type Y Connector Light Rod Hydraulic Cylinder

(8) CA Monoaural Type PHS Fisheye Connector Light Rod Hydraulic Cylinder

(8) CB Binaural Type Light Rod Hydraulic Cylinder

(9) CB With Pin Light Rod Hydraulic Cylinder

Bolt Outline Installation Dimension Drawing:

(10) Standard Biaxial Type Light Rod Hydraulic Cylinder

(11) Standard With Adjustable Cap Type Light Rod Hydraulic Cylinder

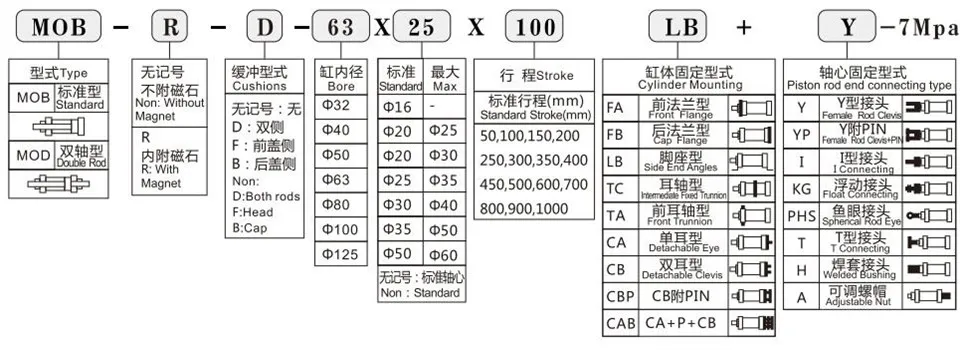

MOB Type Light Rod Hydraulic Cylinder Model Name:

MOB Type Light Rod Hydraulic Cylinder Characteristics:

Mob Light Rod Hydraulic Cylinder Force:

The cylinder diameter and the use pressure determine the force of the MOB light rod hydraulic cylinder. The use pressure is less than or equal to 7Mpa, and the following is the thrust of each different cylinder diameter under the full load of 7Mpa. If the force is pulled, it is less than the thrust.

MOB Light Rod Hydraulic Cylinder Factory 100% Oil Test:

The oil test is carried out on the test bench. The implementation steps are as follows: the oil pipe of the test bench is connected to the oil inlet and outlet of the oil cylinder, the pressure is put on the test bench, the oil of the test bench enters the oil cylinder, and the oil cylinder is reversed through the solenoid valve, so that the oil cylinder can go back and forth several times, and the gap between the rod end of the cylinder, the cylinder and the front and back cover is observed whether there is oil leakage.

Test pressure =7Mpa*1.5=10.5Mpa. Check whether the oil cylinder has been tested; it is straightforward. After receiving the cylinder, remove the plug of the oil port to see whether there is an oil trace. There is an oil trace indicating that the oil test has been done.

Mob Light Rod Hydraulic Cylinder Composition:

MOB light rod hydraulic cylinder is composed of the front cylinder head, rear cylinder head, piston, cylinder, piston rod, 4 screw rods, 8 lock nuts and gaskets, 1 piston lock nut, and gasket, 1 piston rod end matching lock nut, a complete set of seals, rod end protective sleeve, oil plug.

Because the cylinder of this series is only 7Mpa, the front and back covers are made of castings HT200, the piston rod is No. 45 chrome plated layer thickness 2-3 wires, the cylinder barrel is No. 20 rolled tube, and the rod material is A3.

How To Rebuild A Hydraulic Cylinder?

Rebuilding a hydraulic cylinder involves disassembling the cylinder, inspecting and replacing worn or damaged components, and reassembling the cylinder with new seals and other necessary parts. Here’s a step-by-step guide on how to rebuild a hydraulic cylinder:

- Safety Precautions: Before starting any maintenance work on hydraulic cylinders, ensure the system is depressurized, and the equipment is securely immobilized to prevent accidental movement.

- Cylinder Removal: Disconnect the hydraulic lines from the cylinder and remove any mounting brackets or external components that may obstruct access to the cylinder.

- Disassembly: Carefully disassemble the hydraulic cylinder, noting the order and orientation of the components as you remove them. Start by removing the cylinder head or cap, followed by the piston assembly. Do not damage the cylinder bore or other internal components during disassembly.

- Inspection: Thoroughly clean all components and visually inspect them for wear, damage, or signs of corrosion. Evaluate the condition of the cylinder bore, piston, rod, and other internal parts. If any details are excessively worn or damaged, they should be replaced with new ones.

- Seal and O-ring Replacement: Hydraulic cylinder rebuild kits typically include new seals and O-rings. Remove the old seals and O-rings and replace them with the new ones from the kit. Ensure the new seals and O-rings are adequately lubricated with hydraulic oil or a compatible seal lubricant before installation.

- Component Replacement: If other components such as bearings, bushings, or wear rings show signs of wear or damage, replace them with new ones as the manufacturer recommends. Follow the manufacturer’s guidelines for proper installation techniques and torque specifications.

- Cylinder Reassembly: Once all necessary components have been replaced, reassemble the hydraulic cylinder in the reverse order of disassembly. Ensure all parts are fitted correctly, appropriately aligned, and tightened to the manufacturer’s specifications.

- Testing and Inspection: After reassembly, thoroughly inspect the rebuilt cylinder to ensure that all components are properly installed. Check for any signs of leakage, misalignment, or abnormal movement. Slowly pressurize the system and run a test to confirm that the cylinder operates smoothly and efficiently.

- System Bleeding: If required, bleed the hydraulic system to remove any air that may have entered during the rebuilding process. Follow the manufacturer’s recommendations or consult a hydraulic professional for the correct bleeding procedures.

- Documentation: Keep a record of the rebuild, noting the date, components replaced, and any relevant observations or measurements. This documentation can be useful for future reference and maintenance planning.

Tehtaan kapasiteetti ja kapasiteetti:

(1) Kokoonpano

Meillä on ensiluokkainen riippumaton tutkimus- ja kehitystyön kokoonpanoalusta. Hydraulisylinterien tuotantopajassa on neljä puoliautomaattista nostosylinterin kokoonpanolinjaa ja yksi automaattinen kallistussylinterin kokoonpanolinja, joiden suunniteltu vuotuinen tuotantokapasiteetti on 1 miljoona kappaletta. Erikoissylinterin työpaja on varustettu erilaisilla eritelmillä puoliautomaattisen puhdistusasennuksen kokoonpanojärjestelmällä, jonka suunniteltu vuotuinen tuotantokapasiteetti on 200 000, ja se on varustettu kuuluisilla CNC-työstölaitteilla, työstökeskuksella, korkean tarkkuuden sylinterin käsittelyyn tarkoitetuilla erityislaitteilla, robottihitsauskoneella, automaattisella puhdistuslaitteella, automaattisella sylinterin kokoonpanokoneella ja automaattisella maalaustuotantolinjalla. Olemassa olevat kriittiset laitteet yli 300 sarjaa (sarjaa). Laiteresurssien optimaalinen kohdentaminen ja tehokas käyttö varmistavat tuotteiden tarkkuusvaatimukset ja täyttävät tuotteiden laatuvaatimukset.

(2) Koneistus

Työstöpaja on varustettu räätälöidyllä kaltevalla kiskosorvauskeskuksella, työstökeskuksella, suurnopeus-hiontakoneella, hitsausrobotilla ja muilla vastaavilla laitteilla, joilla voidaan käsitellä sylinteriputkia, joiden sisähalkaisija on enintään 400 mm ja enimmäispituus on 6 metriä.

(3) Hitsaus

(4) Maalaus ja pinnoitus

Pienillä ja keskisuurilla sylinterin automaattisilla vesipohjaisilla maalipinnoituslinjoilla automaattisen robotin lastaus- ja purku- ja automaattisen ruiskutuksen saavuttamiseksi, suunnittelukapasiteetti on 4000 kappaletta vuorossa;

Meillä on myös puoliautomaattinen maalauslinja suurille sylintereille, joka toimii voimaketjulla ja jonka suunnittelukapasiteetti on 60 laatikkoa työvuorossa.

(5) Testaus

Meillä on ensiluokkaiset tarkastustilat ja testialustat, joilla varmistetaan, että sylinterin suorituskyky täyttää vaatimukset.

Olemme yksi parhaista kevyen tangon hydraulisylinterin valmistajista. Voimme tarjota laajan kevyen sauvan hydraulisylinterin varaston. Tarjoamme myös vastaavan maatalousvaihteistot. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and tehdä yhteistyötä kanssamme!

Tutustu VR-tehtaaseemme:

Tutustu VR-tehtaaseemme seuraavalla kierroksella

Hydraulisylinteri Sovellus: