V30G Series Heavy Duty Piston Hydraulic Pump

Yhtenä hydraulisylinterien valmistajista, toimittajista ja mekaanisten tuotteiden viejistä tarjoamme hydraulisylintereitä ja monia muita tuotteita.

Ota yhteyttä meihin saadaksesi lisätietoja.

Posti:sales@hydraulic-cylinders.net

Valmistaja toimittaja viejä hydraulisylinterit.

V30G Series Heavy Duty Piston Hydraulic Pump

The V30G series heavy duty piston hydraulic pump is a versatile and robust hydraulic pump designed to deliver high-performance power for demanding industrial applications. With its durable construction, efficient design, and exceptional reliability, this pump is a trusted choice for heavy-duty hydraulic systems. In this article, we will explore the key characteristics, usage methods, and maintenance guidelines for the V30G series heavy duty piston hydraulic pump.

The V30G series heavy duty piston hydraulic pump offers outstanding performance and reliability for heavy-duty industrial applications. With its robust construction, high-pressure capability, and smooth operation, this pump is a trusted choice for demanding hydraulic systems. By following the recommended usage methods and adhering to regular maintenance practices, the v30g series pump will continue to deliver exceptional power and reliability, contributing to the success of industrial operations. Harness the power and reliability of the v30g series heavy duty piston hydraulic pump to optimize your hydraulic system’s capabilities.

V30G Series Heavy Duty Piston Hydraulic Pump Key Characteristics:

- Robust Construction: The V30G series pump is built to withstand rigorous operating conditions. It features a rugged design and high-quality materials, ensuring exceptional durability and longevity even in challenging environments.

- High-Pressure Capability: This hydraulic pump excels in high-pressure applications, delivering the power required for demanding industrial tasks. With its robust piston design and precise engineering, the V30G series pump maintains consistent performance even at high pressures, ensuring optimal efficiency.

- Wide Range of Displacement Options: The V30G series offers a variety of displacement options, allowing users to choose the appropriate pump size to meet the specific requirements of their hydraulic system. This flexibility ensures efficient power delivery and optimized performance.

- Smooth and Quiet Operation: The V30G series pump incorporates advanced technology to minimize noise and vibration during operation. Its precision components and superior engineering result in smooth and quiet performance, reducing operator fatigue and enhancing overall comfort.

V30G Series Heavy Duty Piston Hydraulic Pump Parameter:

| Size | Displacement cc/rev | Pressure bar | Rotation speed rpm | ||

| Rated | Peak | Without impeller | With impeller | ||

| V30G65 | 65 | 420 | 450 | 2500 | – |

| V30G110 | 110 | 420 | 450 | 2400 | – |

| V30G145 | 145 | 420 | 450 | 2300 | 2600 |

| V30G160 | 160 | 420 | 450 | 2200 | 2500 |

| V30G205 | 205 | 420 | 450 | 2100 | 2500 |

| V30G280 | 280 | 420 | 450 | 1800 | 2150 |

V30G Series Heavy Duty Piston Hydraulic Pump Advantages:

• Applied in high pressure open circuit hydraulic systems

• The angle sensor is optional and can be used with the controller to achieve closed-loop high-precision control

• With good self-priming performance, booster pump is optional

• Higher peak pressure, higher resistance to impact and corrosion

• Back cover integration design reduces the risk of leaking

• Optimized case degin reduces vibration and noise

• Reinforced heavy duty bearings ensure longer service life

• Compact structure, high power to weight ratio

• Multiple control methods

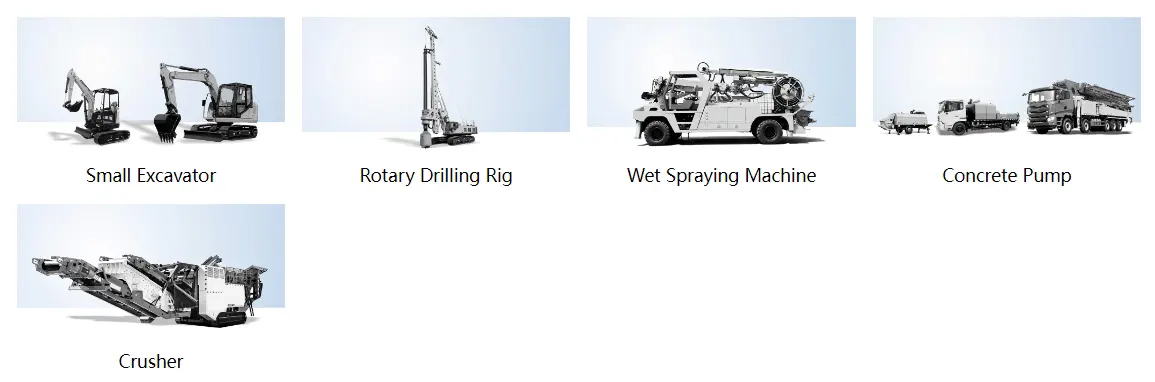

V30G Series Heavy Duty Piston Hydraulic Pump Application:

Usage Method Of V30G Series Heavy Duty Piston Hydraulic Pump:

- Pump Installation: Select a suitable location within the hydraulic system to install the V30G series heavy duty piston hydraulic pump. Ensure proper alignment and securely mount the pump using appropriate brackets or accessories.

- Fluid Compatibility: Verify that the hydraulic fluid used in the system is compatible with the V30G series pump. Refer to the manufacturer’s recommendations for the appropriate fluid type, viscosity, and temperature range. Regularly monitor and maintain the hydraulic fluid to ensure optimal pump operation and longevity.

- Integration with Hydraulic System: Connect the pump to the hydraulic system using compatible hoses, fittings, and valves. Ensure all connections are secure, leak-free, and adequately tightened to maximize hydraulic performance.

- Ohjaus ja toiminta: Familiarize yourself with the control options provided with the V30G series pump. Depending on the specific model, it may offer various control methods such as manual, remote, or electro-hydraulic control. Understand the recommended control settings and adjust them accordingly to optimize pump performance.

How To Repack A Hydraulic Cylinder?

Repacking a hydraulic cylinder involves replacing the seals and other components to restore the cylinder’s performance and prevent leaks. Here’s a step-by-step guide on how to repack a hydraulic cylinder:

- Gather the Necessary Tools and Materials:

- Replacement seals and O-rings suitable for your specific hydraulic cylinder.

- Cylinder repacking kit (if available).

- Wrenches, pliers, or socket set.

- Hydraulic fluid compatible with your system.

- Clean rags or towels.

- Safety gloves and goggles.

- Prepare the Work Area:

- Choose a clean and well-lit workspace to disassemble and repack the cylinder.

- Lay down a protective covering to prevent damage to the cylinder or the work surface.

- Safely Disconnect the Cylinder:

- Shut off the hydraulic system and relieve pressure by activating the pressure release valve.

- Disconnect any hoses or fittings attached to the cylinder.

- Support the weight of the cylinder using appropriate equipment or lifting mechanisms.

- Remove the Cylinder:

- Unscrew the mounting bolts or brackets securing the cylinder to the equipment or machinery.

- Carefully remove the cylinder from its mounting position.

- Disassemble the Cylinder:

- Place the cylinder on a stable work surface and remove the end cap(s) on both ends of the cylinder.

- Drain the hydraulic fluid from the cylinder by tilting it or using a drain plug if available.

- Take note of the order and position of the components as you disassemble the cylinder to aid reassembly.

- Inspect and Clean the Cylinder:

- Examine the cylinder’s internal components, including the piston, rod, and cylinder walls, for signs of damage, wear, or scoring.

- Clean all components thoroughly using a suitable solvent or hydraulic cleaner and clean rags. Ensure there are no debris or contaminants left on the surfaces.

- Replace Seals and O-Rings:

- Remove the old seals and O-rings from the cylinder carefully.

- Install new seals and O-rings using the appropriate installation tools or techniques. Follow the manufacturer’s instructions for proper installation.

- Reassemble the Cylinder:

- Reassemble the cylinder in the reverse order of disassembly, ensuring each component is correctly positioned.

- Apply a thin layer of hydraulic fluid or recommended lubricant to the seals and O-rings before installation.

- Tighten all bolts or fasteners to the manufacturer’s specified torque settings.

- Reinstall the Cylinder:

- Carefully position the cylinder back into its mounting location.

- Reattach the mounting brackets or bolts, ensuring they are securely tightened.

- Reconnect any hoses or fittings, ensuring proper alignment and tight connections.

- Test and Check for Leaks:

- Refill the hydraulic system with the recommended hydraulic fluid.

- Slowly pressurize the system and check for any signs of leaks.

- Operate the hydraulic system through a few cycles to ensure smooth and proper functioning of the repacked cylinder.

Tehtaan kapasiteetti ja kapasiteetti:

(1) Kokoonpano

Meillä on ensiluokkainen riippumaton tutkimus- ja kehitystyön kokoonpanoalusta. Hydraulisylinterien tuotantopajassa on neljä puoliautomaattista nostosylinterin kokoonpanolinjaa ja yksi automaattinen kallistussylinterin kokoonpanolinja, joiden suunniteltu vuotuinen tuotantokapasiteetti on 1 miljoona kappaletta. Erikoissylinterin työpaja on varustettu erilaisilla eritelmillä puoliautomaattisen puhdistusasennuksen kokoonpanojärjestelmällä, jonka suunniteltu vuotuinen tuotantokapasiteetti on 200 000, ja se on varustettu kuuluisilla CNC-työstölaitteilla, työstökeskuksella, korkean tarkkuuden sylinterin käsittelyyn tarkoitetuilla erityislaitteilla, robottihitsauskoneella, automaattisella puhdistuslaitteella, automaattisella sylinterin kokoonpanokoneella ja automaattisella maalaustuotantolinjalla. Olemassa olevat kriittiset laitteet yli 300 sarjaa (sarjaa). Laiteresurssien optimaalinen kohdentaminen ja tehokas käyttö varmistavat tuotteiden tarkkuusvaatimukset ja täyttävät tuotteiden laatuvaatimukset.

(2) Koneistus

Työstöpaja on varustettu räätälöidyllä kaltevalla kiskosorvauskeskuksella, työstökeskuksella, suurnopeus-hiontakoneella, hitsausrobotilla ja muilla vastaavilla laitteilla, joilla voidaan käsitellä sylinteriputkia, joiden sisähalkaisija on enintään 400 mm ja enimmäispituus on 6 metriä.

(3) Hitsaus

(4) Maalaus ja pinnoitus

Pienillä ja keskisuurilla sylinterin automaattisilla vesipohjaisilla maalipinnoituslinjoilla automaattisen robotin lastaus- ja purku- ja automaattisen ruiskutuksen saavuttamiseksi, suunnittelukapasiteetti on 4000 kappaletta vuorossa;

Meillä on myös puoliautomaattinen maalauslinja suurille sylintereille, joka toimii voimaketjulla ja jonka suunnittelukapasiteetti on 60 laatikkoa työvuorossa.

(5) Testaus

Meillä on ensiluokkaiset tarkastustilat ja testialustat, joilla varmistetaan, että sylinterin suorituskyky täyttää vaatimukset.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding maatalousvaihteistot. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and tehdä yhteistyötä kanssamme!

Tutustu VR-tehtaaseemme:

Tutustu VR-tehtaaseemme seuraavalla kierroksella

Hydraulisylinteri Sovellus: