Vérin hydraulique métallurgique à tête rectangulaire et à bride

En tant que fabricant, fournisseur et exportateur de produits mécaniques, nous proposons des vérins hydrauliques et de nombreux autres produits.

N'hésitez pas à nous contacter pour plus de détails.

Courrier :sales@hydraulic-cylinders.net

Fabricant fournisseur exportateur de vérins hydrauliques.

Vérin hydraulique métallurgique à tête rectangulaire et à bride

The rectangular flange type metallurgical hydraulic cylinder is a state-of-the-art element specially designed for metallurgical applications. With its innovative design, superior performance, and rugged construction, this hydraulic cylinder ensures precise control, reliable operation, and exceptional durability in demanding industrial environments. Whether used in steel mills, foundries, or other metallurgical processes, head rectangular flange-type cylinders provide efficiency and productivity.

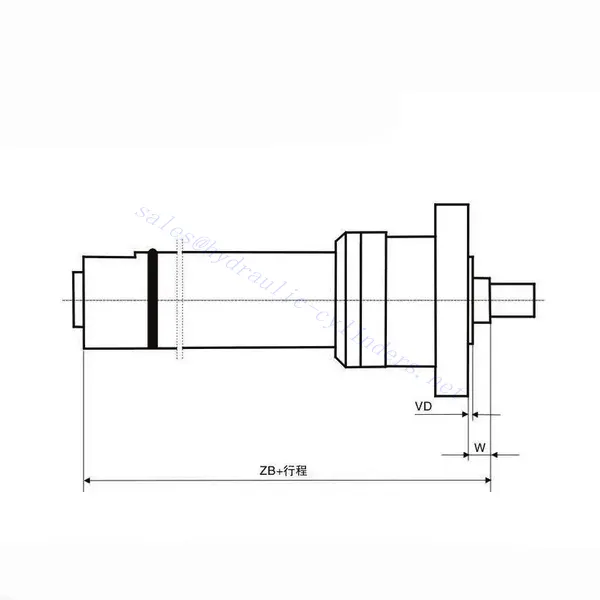

The hydraulic cylinder of Y-HG1 series metallurgical equipment is a double-acting piston cylinder; the cylinder diameter is generally within the range of 40~320mm, and the working pressure is <=16MPA. The hydraulic oil system can transport the active medium, such as emulsion, and install different models, such as flanges, earrings, pins, and release devices (base).

High precision CNC honing machine, automatic welding machine, vertical, horizontal machining center, gantry machining center, CNC lathe, and other processing equipment, product quality is stable and guaranteed.

Head Rectangular Flange Type Metallurgical Hydraulic Cylinder Parameter:

Vérin hydraulique métallurgique à tête rectangulaire et à bride Usage Method:

- Mounting and Installation:

- Identify the appropriate mounting location for the metallurgical hydraulic cylinder based on the specific requirements of the metallurgical equipment.

- Ensure that the mounting surface is clean, flat, and capable of supporting the weight and load of the cylinder.

- Connection to Hydraulic System:

- Connect the metallurgical hydraulic cylinder to the hydraulic system using compatible hydraulic hoses or pipes.

- Ensure proper alignment and secure connections to prevent leaks.

- System Integration and Calibration:

- Integrate the metallurgical hydraulic cylinder into the metallurgical equipment or system following the manufacturer’s guidelines.

- Calibrate the system to achieve optimal performance and desired operation parameters.

- Operating the Cylinder:

- Activate the hydraulic system to apply pressure and initiate the movement of the hydraulic cylinder.

- Utilize the hydraulic control system to control the cylinder’s extension, retraction, and precise positioning for efficient metallurgical operations.

Caractéristiques Of Head Rectangular Flange Type Metallurgical Hydraulic Cylinder:

- Head Rectangular Flange Design: The unique rectangular flange design provides enhanced stability, precise alignment, and improved load distribution during operation, ensuring optimal performance in metallurgical processes.

- Metallurgical Application Focus: This metallurgical hydraulic cylinder is precisely engineered to meet the demanding requirements of metallurgical applications, offering reliability and durability in extreme conditions.

- Superior Performance: The cylinder delivers exceptional performance, enabling accurate positioning, smooth operation, and efficient productivity in metallurgical processes.

- Robust Construction: Constructed from high-quality materials and designed to withstand heavy loads and harsh operating conditions, this metallurgical hydraulic cylinder ensures long-term durability and reliable performance.

- Safety Features: The design incorporates overload protection and emergency stop mechanisms, prioritizing operator safety during metallurgical processes.

Comment trouver un kit d'étanchéité pour vérin hydraulique ?

Finding the correct seal kit for a hydraulic cylinder is crucial to ensure proper fit, functionality, and performance. Here are some steps to help you find the appropriate seal kit:

- Identify the Cylinder Manufacturer and Model:

- Determine the manufacturer of the hydraulic cylinder. This information is often stamped or engraved on the cylinder body.

- If possible, note down the model number or any other identifying markings on the cylinder.

- Gather Cylinder Specifications:

- Measure the dimensions of the cylinder, including the bore diameter, rod diameter, and stroke length.

- Note any specific features or configurations unique to the cylinder, such as flanges, ports, or mounting styles.

- Research the Manufacturer’s Resources:

- Visit the manufacturer’s website or contact customer support to inquire about available seal kits for your specific cylinder model.

- Provide the manufacturer with the cylinder specifications and any identifying information you have gathered.

- Explore Online Hydraulic Seal Suppliers:

- Search for reputable online hydraulic seal suppliers or distributors.

- Utilize search filters or navigation menus on their websites to narrow down the selection based on cylinder specifications or manufacturer.

- Utilize Seal Kit Cross-Reference Tools:

- Some seal kit suppliers offer cross-reference tools or databases that help match cylinder models with compatible seal kits.

- Enter the cylinder manufacturer, model, or other specifications into the cross-reference tool to find suitable seal kits.

- Consult Hydraulic System Maintenance Manuals:

- Check if the equipment or machinery that uses the hydraulic cylinder has a maintenance manual.

- The manual may include information on recommended seal kits or part numbers.

- Seek Assistance from Hydraulic Experts:

- Reach out to hydraulic system specialists, maintenance professionals, or engineers with expertise in hydraulic systems.

- They can guide and recommend finding the correct seal kit for your hydraulic cylinder.

- Consider Custom Seal Kits:

- If you cannot find a seal kit specifically designed for your cylinder model, consider contacting a manufacturer or supplier that offers custom seal kits.

- Please provide them with accurate measurements and cylinder specifications to have a seal kit tailored to your requirements.

- Purchase and Install the Seal Kit:

- Once you have identified the appropriate seal kit, place an order with the supplier or manufacturer.

- Follow the installation instructions with the seal kit carefully to ensure proper installation and optimal performance.

Capacité de l'usine :

(1) Assemblage

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Usinage

L'atelier d'usinage est équipé d'un centre de tournage sur rail incliné personnalisé, d'un centre d'usinage, d'une machine à honer à grande vitesse, d'un robot de soudage et d'autres équipements connexes, qui peuvent traiter des tubes cylindriques d'un diamètre intérieur maximal de 400 mm et d'une longueur maximale de 6 mètres.

(3) Soudage

(4) Peinture et revêtement

Avec des lignes de revêtement de peinture à base d'eau automatiques à cylindre de petite et moyenne taille, pour réaliser le chargement et le déchargement automatiques par robot et la pulvérisation automatique, la capacité de conception est de 4 000 pièces par équipe ;

Nous disposons également d'une ligne de production de peinture semi-automatique pour gros cylindres, alimentée par une chaîne de traction, d'une capacité de conception de 60 caisses par équipe.

(5) Essais

Nous disposons d'installations d'inspection et de bancs d'essai de premier ordre pour garantir que les performances de la bouteille sont conformes aux exigences.

We are one of the best metallurgical hydraulic cylinder manufacturers. We can offer comprehensive metallurgical hydraulic cylinder stock. We also provide corresponding boîtes de vitesses agricoles. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and coopérer avec nous!

Visitez notre usine de RV :

Visitez notre usine de RV avec les éléments suivants

Comment fonctionne le vérin hydraulique d'un chariot élévateur ?

Vérin hydraulique Application :