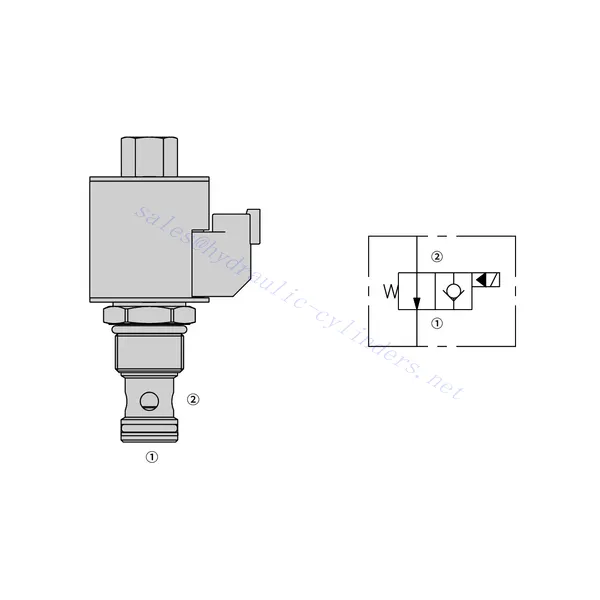

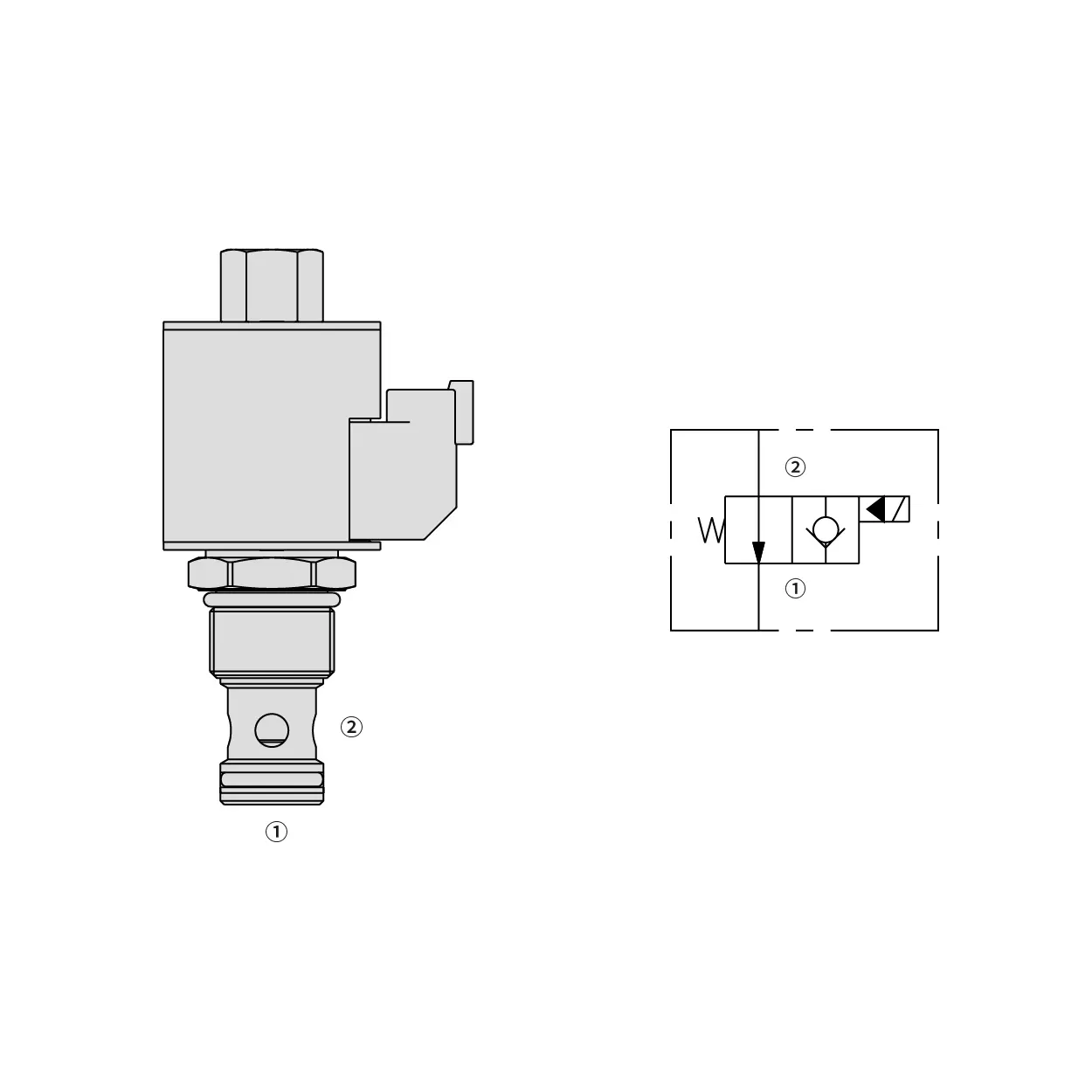

35SD12-21 Solenoid Directional Valve

En tant que fabricant, fournisseur et exportateur de produits mécaniques, nous proposons des vérins hydrauliques et de nombreux autres produits.

N'hésitez pas à nous contacter pour plus de détails.

Courrier :sales@hydraulic-cylinders.net

Fabricant fournisseur exportateur de vérins hydrauliques.

35SD12-21 Solenoid Directional Valve

The 35SD12-21 solenoid directional valve is an essential component in fluid systems, offering precise and efficient control over the flow of fluids. Designed with advanced technology and superior craftsmanship, this valve provides reliable and effective performance in various industrial applications.

The 35SD12-21 solenoid directional valve is indispensable for precise and efficient fluid control in industrial applications. Its high-quality construction, rapid response times, and versatile usage methods provide reliable and accurate performance in various fluid systems. By adhering to proper maintenance practices, industries can ensure this valve’s longevity and optimal functionality. Invest in the 35SD12-21 solenoid directional valve to enhance fluid control, improve operational efficiency, and achieve exceptional results in your fluid system operations.

35SD12-21 Solenoid Directional Valve Characteristics:

- High-Quality Construction: Crafted with precision using durable materials, this valve ensures longevity and resistance to wear and corrosion, even in demanding environments.

- Quick and Responsive: The solenoid design of the valve enables rapid response times, allowing for precise control over fluid flow and pressure.

- Compact and Space-Saving: With its compact size, the 35SD12-21 Solenoid Directional Valve is ideal for applications with limited space or where multiple valves need to be installed nearby.

- Versatile Mounting Options: This valve offers flexible mounting options, including inline, manifold, or subplate mounting, providing ease of installation and integration into various fluid systems.

35SD12-21 Solenoid Directional Valve Parameter:

35SD12-21 Solenoid Directional Valve Advantages:

• Continuous-duty rated coil

• Cartridges are voltage interchangeable

• Optional waterproof E-Coils rated up to IP69K

• Efficient wet-armature construction

• Industry common cavity

• Hardened parts for long life

Usage Method Of 35SD12-21 Solenoid Directional Valve :

- Fluid Flow Control: This valve allows for accurate regulation of fluid flow, enabling precise control over the speed, direction, and pressure of the fluid in hydraulic, pneumatic, or other fluid systems.

- Actuation of Cylinders: The 35SD12-21 Solenoid Directional Valve is commonly used to actuate cylinders in industrial machinery, allowing for precise movement and positioning.

- Process Automation: It plays a crucial role in automated processes, facilitating the control of fluid flow to different parts of the system based on specific operational requirements.

- Safety and Emergency Shutdown: This valve can be utilized as a safety measure, providing emergency shutdown capabilities in critical situations to prevent damage or accidents.

How To Replace A Delta Shower Valve Cartridge?

Replacing a Delta shower valve cartridge is a straightforward process that can be completed with a few basic tools. Here’s a step-by-step guide on how to replace a Delta shower valve cartridge:

- Gather the necessary tools: You will need an adjustable wrench, a screwdriver (Phillips or flathead, depending on your specific shower valve), a cartridge removal tool (included in some replacement cartridge kits), and a new Delta shower valve cartridge.

- Turn off the water supply: Locate the main water shut-off valve for your home and turn it off to ensure no water flows to the shower. If you have a dedicated shut-off valve for the shower, you can use that instead.

- Remove the handle and trim: Depending on the type of handle, you may need to unscrew it or pry off a decorative cap to access the screw holding it in place. Use a screwdriver to remove the screw and gently pull off the handle. Next, remove any trim or decorative coverings around the valve, exposing the cartridge.

- Remove the old cartridge: Look for a retaining clip or nut securing the cartridge in place. Use pliers or an adjustable wrench to loosen and remove the clip or nut. Once it’s removed, you can pull out the old cartridge. If it’s stuck, you can use a cartridge removal tool to assist in pulling it out.

- Install the new cartridge: Take the new Delta shower valve cartridge and align it with the valve body. Ensure that any alignment tabs or notches match up correctly. Gently push the cartridge into place until it sits flush with the valve body.

- Reassemble the valve: Replace the retaining clip or nut to secure the new cartridge in place. Double-check that it’s firmly in position.

- Test for leaks: Slowly turn on the water supply, and check for any leaks around the valve. If you notice any leaks, tighten the cartridge or connections as needed.

- Reinstall the trim and handle: Put back the trim or decorative coverings over the valve. Slide the handle back onto the cartridge stem and secure it with the retaining screw. If applicable, reattach any decorative cap or cover.

- Turn on the water supply: Once everything is securely reinstalled, turn on the water supply and check for proper functioning. Test the hot and cold water settings to ensure they’re working correctly.

Capacité de l'usine :

(1) Assemblage

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Usinage

L'atelier d'usinage est équipé d'un centre de tournage sur rail incliné personnalisé, d'un centre d'usinage, d'une machine à honer à grande vitesse, d'un robot de soudage et d'autres équipements connexes, qui peuvent traiter des tubes cylindriques d'un diamètre intérieur maximal de 400 mm et d'une longueur maximale de 6 mètres.

(3) Soudage

(4) Peinture et revêtement

Avec des lignes de revêtement de peinture à base d'eau automatiques à cylindre de petite et moyenne taille, pour réaliser le chargement et le déchargement automatiques par robot et la pulvérisation automatique, la capacité de conception est de 4 000 pièces par équipe ;

Nous disposons également d'une ligne de production de peinture semi-automatique pour gros cylindres, alimentée par une chaîne de traction, d'une capacité de conception de 60 caisses par équipe.

(5) Essais

Nous disposons d'installations d'inspection et de bancs d'essai de premier ordre pour garantir que les performances de la bouteille sont conformes aux exigences.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding boîtes de vitesses agricoles. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and coopérer avec nous!

Visitez notre usine de RV :

Visitez notre usine de RV avec les éléments suivants

Vérin hydraulique Application :