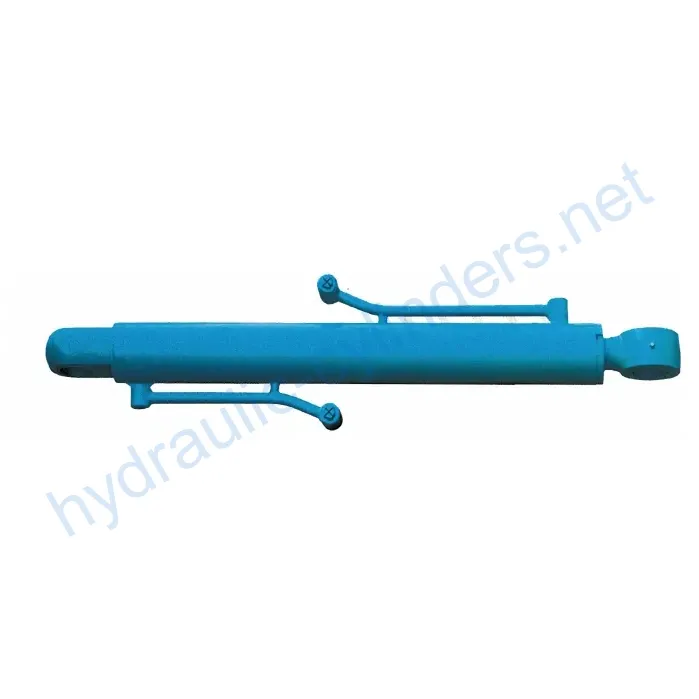

Bucket Cylinder For Caterpillar Middle Excavator E240BL

En tant que fabricant, fournisseur et exportateur de produits mécaniques, nous proposons des vérins hydrauliques et de nombreux autres produits.

N'hésitez pas à nous contacter pour plus de détails.

Courrier :sales@hydraulic-cylinders.net

Fabricant fournisseur exportateur de vérins hydrauliques.

Bucket Cylinder For Caterpillar Middle Excavator E240BL

Introduction

A bucket cylinder is a specially designed hydraulic cylinder used to control the movement of buckets in heavy-duty machinery such as excavators, backhoes, and front loaders. Its main function is to enable the bucket to perform lifting, lowering, and tilting actions, making it easier to handle various material handling tasks. In the hydraulic system, the bucket cylinder achieves precise control of the bucket’s movement through changes in hydraulic oil pressure, allowing operators to efficiently handle heavy loads and adapt to complex work environments and diverse operational requirements.

Features

- High strength and durability: Typically made of high-strength steel or aluminum, it can withstand high pressure and heavy loads, adapt to harsh working environments, and is designed to consider wear resistance and corrosion resistance, extending its service life.

- Efficient hydraulic operation: Smooth extension and contraction actions are achieved by utilizing the pressure of hydraulic oil, and it can quickly respond to control commands, providing powerful pushing and pulling forces, making it suitable for handling heavy loads and complex job tasks.

- Various types: Single-acting (hydraulic used in one direction) or double-acting (hydraulic used in two directions) cylinders can be selected according to requirements to meet different operational needs. Some models are telescopic, allowing for greater extension without increasing external dimensions, making them suitable for applications with limited space.

- Our product can perfectly replace these hydraulic cylinders.

Applications

The bucket cylinder is used in a variety of heavy machinery:

- Construction equipment: They are essential for excavators in digging, loading, and moving soil or debris. In backhoes, the bucket cylinder helps both in excavation and lifting.

- Agricultural machinery: Used in front-end loaders for scooping, lifting, and transporting soil, hay, and other materials.

- Excavators: Bucket cylinders enable digging action by allowing the bucket to penetrate the soil.

- Loaders: In front loaders, they help in lifting and tilting goods effectively.

Design Considerations and Selection Criteria

The design of the bucket cylinder is essential to ensure its ability to perform reliably in harsh working conditions. The following are some critical design considerations and selection criteria:

- Bearing capacity: It must be able to withstand high pressure and heavy loads.

- Sealing: It must have high-quality sealing elements, such as piston seals and rod seals, that are made of wear-resistant materials such as polyurethane and nitrile rubber.

- Durability: The cylinder body and threaded end surfaces must be finely processed to improve wear resistance.

- Safety: It must have safety features such as bypass valves and pressure relief valves to prevent overloading.

- Maintainability: It must have easy-to-replace wear parts and easy-to-disassemble design for maintenance.

Sealing and Lubrication

The bucket cylinder requires various sealing elements to prevent oil leakage and ensure proper lubrication. The following are some important points to consider:

- Use various sealing elements such as piston seals and rod seals

- Select sealing elements made of wear-resistant materials such as polyurethane and nitrile rubber

- Make sure the cylinder body and threaded end surfaces are finely processed to improve wear resistance

- Regularly add appropriate hydraulic oil to lubricate

Maintenance and Repair

The bucket cylinder requires regular inspection and preventive maintenance to ensure its optimal performance and durability. The following are some common maintenance tasks:

- Regular inspection

- Proper lubrication

- Seal replacement

- Calibration check

Safety and Environmental Considerations

When using the bucket cylinder, safety measures should be taken to ensure safe operation. Moreover, environmental considerations, such as oil leakage, should also be taken into account.

Diagnostic and Common Problems

The following are some common problems that may occur when using the bucket cylinder:

- Oil leakage

- Insufficient pressure

- Slow movement

- Excessive vibration

Company Introduction

We are a manufacturer of hydraulic cylinders that can replace the original cylinders. Our company’s products are diverse and have become one of the leading manufacturers and wholesale distributors of hydraulic cylinders in the domestic and international markets. We follow the principle of excellent quality and rely on industrial production management strategies in finely-manufactured workshops. We continuously improve our manufacturing platforms and perfect our product quality production lines, and have strong creation capabilities. Our customers’ diverse needs are met based on our principles of high efficiency, high accuracy, and high quality.

Our company also provides customized services and international certifications, including ISO9001, ISO14001, and CE certification. We have professional production equipment and after-sales services, including spare parts replacement and rebuild services to ensure the long service life of our products.

Author: lyl

Visitez notre usine de RV :

Visitez notre usine de RV avec les éléments suivants

Vérin hydraulique Application :