Replacement Of F710320 Hydraulic Cylinder

En tant que fabricant, fournisseur et exportateur de produits mécaniques, nous proposons des vérins hydrauliques et de nombreux autres produits.

N'hésitez pas à nous contacter pour plus de détails.

Courrier :sales@hydraulic-cylinders.net

Fabricant fournisseur exportateur de vérins hydrauliques.

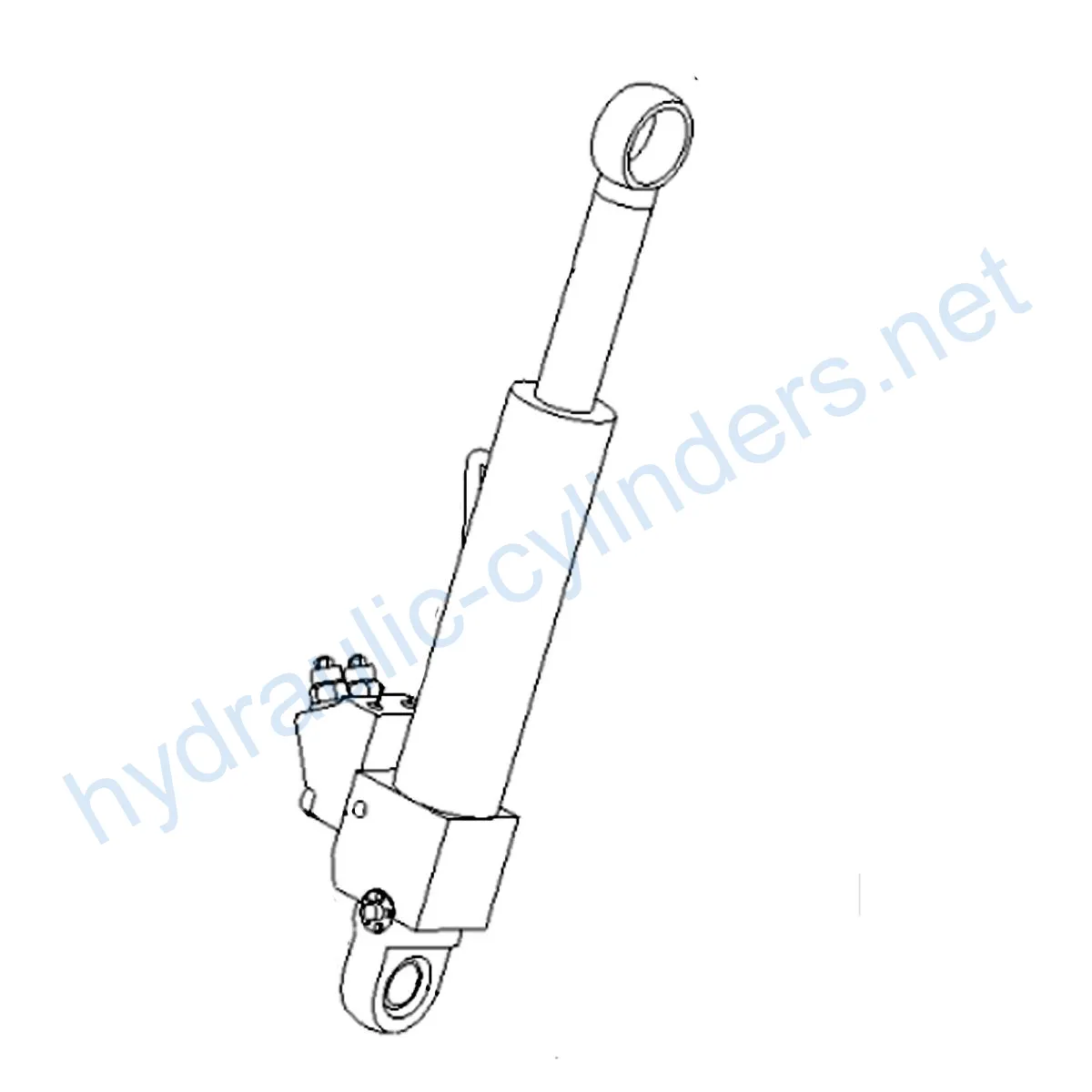

Replacement Of F710320 Hydraulic Cylinder

The Replacement Of F710320 Hydraulic Cylinder is a device used in hydraulic systems to convert the energy of fluid pressure into mechanical force. It is commonly used in heavy machinery such as excavators, cranes, tractors, harvesters, and mining equipment. The Replacement Of F710320 Hydraulic Cylinder is designed to replace damaged or worn cylinders and restore the equipment to its normal operating capability, ensuring performance in various applications and enhancing safety features.

Specifications and Models

Specifications:

- Weight: 40.084 lb

- Height: 5 in

- Width: 8 in

- Length: 23 in

Models:

The Replacement Of F710320 Hydraulic Cylinder is suitable for the 1070E and 1170E models.

Features

The Replacement Of F710320 Hydraulic Cylinder has several features that make it an excellent choice for heavy machinery. Here are some examples:

- Improves Equipment Performance: Replacing damaged or worn hydraulic cylinders can restore normal operations and ensure proper performance in various applications.

- Enhances Safety: Regularly replacing hydraulic cylinders can reduce safety hazards caused by cylinder failure, ensuring operator and equipment safety.

- Overload Protection: Modern cylinder designs usually consider better overload protection mechanisms, enhancing safety features.

- Quick Installation: Modern hydraulic cylinders are designed for easy installation and replacement, reducing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it easier to obtain replacement parts on the market.

Our company can produce Replacement Of F710320 Hydraulic Cylinder, which can perfectly replace these hydraulic cylinders.

Applications

The Replacement Of F710320 Hydraulic Cylinder is used in various applications. Here are some examples:

- Excavators: The hydraulic cylinder on the arm or bucket of an excavator may be damaged due to long-term usage or overload and needs to be replaced to restore normal operation.

- Cranes: The lifting arm hydraulic cylinder of a crane is susceptible to wear and tear during the frequent lifting and lowering process and needs to be replaced regularly to ensure safety.

- Tractors: The front-end loader hydraulic cylinder of a tractor may leak or performance may degrade during constant lifting and tilting, necessitating replacement.

- Harvesters: The hydraulic system of a harvester is subject to high pressure during operation, and the cylinder may become damaged due to fatigue, requiring timely replacement to maintain work efficiency.

- Automated Production Line: Hydraulic cylinders are used to control robotic arms and other automation equipment. Any cylinder malfunction can affect production efficiency and requires immediate replacement.

- Die-Casting Machine: In high-pressure and high-temperature environments, hydraulic cylinders may experience performance degradation. Regular replacement can ensure product quality.

- Mining Equipment: Hydraulic cylinders are used to lift and move heavy objects in mining equipment. Due to the harsh working environment, regular inspections and replacement are necessary to avoid equipment failure.

- Bulldozers: The wear of the hydraulic cylinder on the bulldozer’s pushing arm can lead to a decrease in pushing capacity and requires timely replacement to maintain operational efficiency.

Maintenance

Regular maintenance is crucial for the Replacement Of F710320 Hydraulic Cylinder to ensure proper functioning and prolong lifespan. Here are some common maintenance tasks:

- Regular Inspection: Inspect the hydraulic cylinder regularly to identify any damage or wear.

- Proper Lubrication: Use appropriate lubricants to ensure smooth functioning, increase lifespan, and protect from corrosion.

- Seal Replacement: Regularly replace seals to prevent fluid leakage and ensure proper functioning.

- Calibration Check: Regularly check the cylinder’s calibration to ensure proper functioning.

It is important to provide proper installation guidance, including aligning the cylinder correctly and using appropriate installation supports to secure the cylinder. We recommend following the recommended inspection, repair, and replacement procedures, providing replacement parts and rebuilding services to enhance the cylinder’s lifespan.

Safety and Environmental Considerations

When using hydraulic cylinders, safety measures are crucial to ensure operator and equipment safety. Proper use of protective gear, such as gloves and eyewear, is recommended to prevent injury. Additionally, it is important to follow all safety guidelines provided in the equipment manual.

Environmental factors such as temperature, humidity, and exposure to chemicals can affect the performance of hydraulic cylinders. Proper maintenance and replacement of worn-out cylinders are necessary to prevent environmental damage and ensure equipment safety.

Troubleshooting and Common Issues

Hydraulic cylinders may experience issues such as fluid leakage, loss of pressure, and abnormal noises. Here are some tips and solutions for diagnosing and solving problems:

- Fluid Leakage: Check for damaged seals, loose fittings, or worn-out pistons. Replace or repair the damaged parts.

- Loss of Pressure: Check for damaged hoses or a clogged or damaged valve. Repair or replace the damaged parts.

- Abnormal Noises: Check for damaged bearings or loose connections. Tighten the connections or replace the damaged bearings.

To prevent problems, it is important to follow recommended maintenance procedures, including regular inspection, proper lubrication, and seal replacement. Additionally, it is crucial to follow safety guidelines and use protective gear to prevent injury.

Design Considerations and Selection Criteria

When selecting a hydraulic cylinder, it is important to consider factors such as load-carrying capacity, sealing, durability, safety, and maintainability. Here are some design considerations:

- Load-Carrying Capacity: Choose a cylinder with a load-carrying capacity that matches the requirements of the equipment.

- Sealing: Choose a cylinder with appropriate seals to ensure proper functioning and prevent fluid leakage.

- Durability: Choose a cylinder made of durable materials that can withstand harsh environmental conditions and frequent usage.

- Safety: Choose a cylinder that meets safety standards and is designed to prevent malfunctions.

- Maintainability: Choose a cylinder that is designed to be easy to maintain and replace.

Proper selection and maintenance of hydraulic cylinders can ensure efficient and safe operation of equipment.

About Our Company

We are a leading manufacturer and wholesale distributor of hydraulic cylinders, offering a wide range of products for domestic and international markets. Our company provides customized services, and all our products are certified for international standards. We use advanced production equipment to ensure product quality, and our customer service team provides excellent after-sales support.

Our company is dedicated to providing high-quality hydraulic cylinders that meet the demands of heavy machinery and ensure efficient and safe operation.

Author: lyl

Visitez notre usine de RV :

Visitez notre usine de RV avec les éléments suivants

Vérin hydraulique Application :