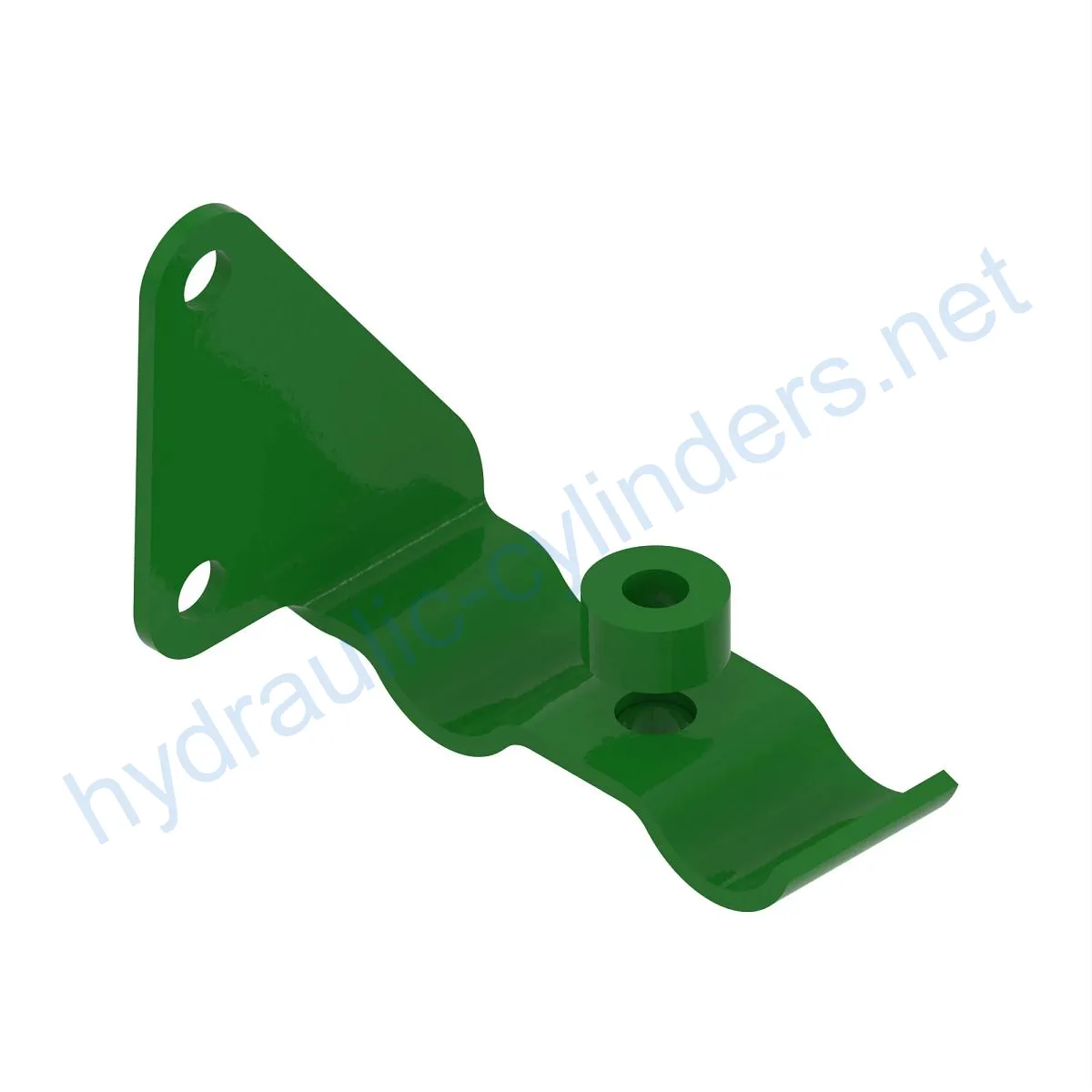

Replacement Of RE19217 Hydraulic Cylinder Repair Kit

En tant que fabricant, fournisseur et exportateur de produits mécaniques, nous proposons des vérins hydrauliques et de nombreux autres produits.

N'hésitez pas à nous contacter pour plus de détails.

Courrier :sales@hydraulic-cylinders.net

Fabricant fournisseur exportateur de vérins hydrauliques.

Product Introduction

The Replacement Of RE19217 Hydraulic Cylinder Repair Kit is a crucial component in hydraulic systems. It serves the important purpose of repairing and replacing damaged or worn hydraulic cylinders, ensuring the smooth operation of equipment. With a weight of 0.21 lb and dimensions of 1 in (height), 8.5 in (width), and 11 in (length), this product is designed to fit the 570B model.

Product Specifications

- Weight: 0.21 lb

- Height: 1 in

- Width: 8.5 in

- Length: 11 in

Product Features

- Improved Equipment Performance: Replacing damaged or worn hydraulic cylinders can restore the normal operational capabilities of equipment, ensuring optimal performance in various applications.

- Enhanced Safety: Regularly replacing hydraulic cylinders can reduce safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

- Overload Protection: New cylinder designs often incorporate better overload protection mechanisms, enhancing overall safety.

- Quick Installation: Modern hydraulic cylinders are designed with ease of installation and replacement in mind, minimizing downtime.

- Standardized Components: Many hydraulic cylinders are standardized products, making it convenient to obtain replacement parts in the market.

Applications

The Replacement Of RE19217 Hydraulic Cylinder Repair Kit finds its application in various scenarios:

- Excavators: Damaged hydraulic cylinders on the boom or bucket of excavators may need replacement after extended use or overloading to restore normal operation.

- Cranes: Hydraulic cylinders on the lifting arms of cranes are prone to wear due to frequent lifting and lowering, requiring regular replacements for safety assurance.

- Tractors: Hydraulic cylinders on the front loaders of tractors may develop leaks or performance degradation due to constant lifting and tilting operations, necessitating replacements.

- Harvesters: Hydraulic cylinders in harvesting equipment endure high pressure during the harvesting process and may get damaged due to fatigue, requiring timely replacements to maintain efficiency.

- Automated Production Lines: Hydraulic cylinders control robotic arms and other automated equipment. Cylinder failures can significantly impact production efficiency, necessitating immediate replacements.

- Die Casting Machines: In high-pressure and high-temperature environments, hydraulic cylinders may experience performance degradation. Regular replacements ensure product quality.

- Mining Equipment: Hydraulic cylinders are used for lifting and moving heavy loads in mining equipment. Regular inspections and replacements are necessary to prevent equipment failures in harsh working conditions.

- Bulldozers: Worn hydraulic cylinders on the bulldozer’s blade can lead to reduced pushing capability, requiring timely replacements to maintain operational efficiency.

Maintenance Tasks

Regular maintenance tasks for the Replacement Of RE19217 Hydraulic Cylinder Repair Kit include:

- Periodic Inspections: Regularly inspect the hydraulic cylinder for any signs of damage or wear.

- Proper Lubrication: Ensure proper lubrication of the cylinder to reduce friction and extend its lifespan.

- Seal Replacement and Calibration Checks: Replace seals as needed and perform calibration checks to ensure optimal performance.

Safety Considerations and Environmental Factors

When using hydraulic cylinders, it is important to follow safety precautions to prevent accidents and injuries. Additionally, considering environmental factors when selecting and using hydraulic cylinders can minimize their impact on the environment.

Troubleshooting and Common Issues

Common issues related to hydraulic cylinders include:

- Leaking Seals: Check for any signs of seal leaks and replace them if necessary.

- Slow or Erratic Operation: Inspect the cylinder for any obstructions or irregularities that may affect its operation.

- Loss of Power: Check the hydraulic system for any malfunctions that may cause a loss of power in the cylinder.

Preventive Measures and Troubleshooting Tips

To diagnose and resolve issues effectively, consider the following tips:

- Regularly inspect and maintain the hydraulic cylinder.

- Follow recommended installation, lubrication, and adjustment procedures.

- Provide proper alignment guidance during installation.

- Use appropriate mounting brackets to secure the cylinder.

- Recommend inspection, repair, and replacement procedures.

- Offer replacement parts and rebuilding services to extend the lifespan of the hydraulic cylinder.

Product Design Considerations and Selection Criteria

When choosing hydraulic cylinders, it is important to consider the following design considerations:

- Bearing Capacity: Ensure the hydraulic cylinder can handle the required load to prevent failures.

- Sealing Capability: Choose hydraulic cylinders with high-quality seals to prevent leaks and maintain optimal performance.

- Durability: Opt for cylinders made from durable materials to withstand the demanding conditions of various applications.

- Safety: Consider safety features and certifications when selecting hydraulic cylinders to ensure safe operation.

- Maintainability: Choose cylinders that are easy to maintain and repair to minimize downtime.

Sealing and Lubrication

Proper sealing and lubrication are vital for the performance of hydraulic cylinders. This includes using various sealing components, such as piston seals and rod seals, made from wear-resistant materials like polyurethane and nitrile rubber. Additionally, the cylinder body and threaded end surfaces are finely processed to enhance wear resistance. Regularly adding the appropriate amount of hydraulic oil for lubrication is also essential.

Regular Inspection and Preventive Maintenance

To prolong the lifespan of hydraulic cylinders, it is recommended to perform regular inspections and preventive maintenance tasks. This includes proper installation, lubrication, and adjustment. Providing accurate alignment guidance during installation and recommending the use of suitable mounting brackets to secure the cylinder are essential. It is also important to follow recommended inspection, repair, and replacement procedures, as well as offering replacement parts and rebuilding services.

Installation Guide

Proper installation is crucial for the performance and longevity of hydraulic cylinders. Follow these steps for correct installation:

- Prepare the mounting surface and ensure it is clean and free from debris.

- Align the cylinder with the mounting holes and insert bolts.

- Tighten the bolts evenly to the recommended torque specification.

- Connect the hydraulic lines, ensuring proper sealing and tight connections.

- Test the cylinder for proper operation before putting it into full use.

Visitez notre usine de RV :

Visitez notre usine de RV avec les éléments suivants

Vérin hydraulique Application :