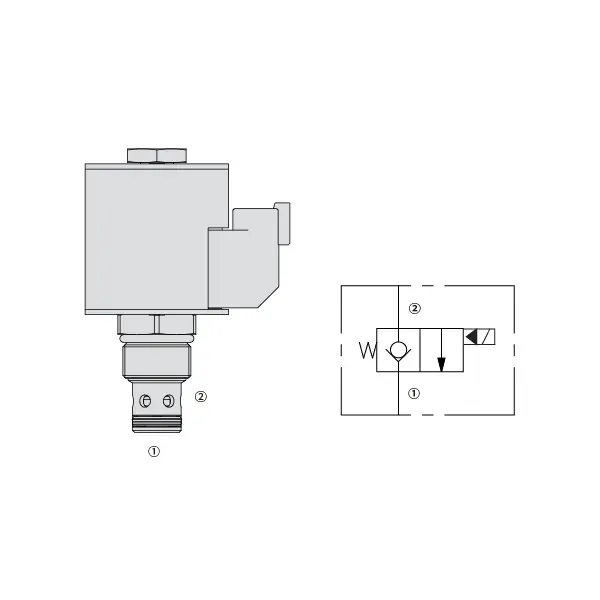

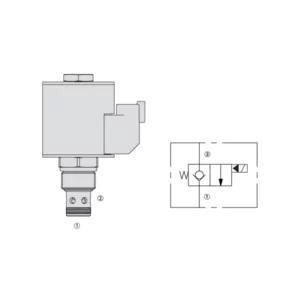

35SD10-20 Solenoid Directional Valve

Sebagai salah satu produsen, pemasok, dan eksportir silinder hidrolik, Kami menawarkan silinder hidrolik dan banyak produk lainnya.

Silakan hubungi kami untuk informasi lebih lanjut.

Surat:sales@hydraulic-cylinders.net

Produsen pemasok eksportir silinder hidrolik.

35SD10-20 Solenoid Directional Valve

The 35SD10-20 Solenoid Directional Valve is a powerful and versatile component designed to optimize fluid control in a wide range of industrial applications. With its advanced features, precise operation, and reliable performance, this solenoid valve is a valuable tool for enhancing fluid control efficiency and productivity. Whether in manufacturing, automation, or process control, the 35SD10-20 Solenoid Directional Valve delivers exceptional functionality and versatility, making it an essential component for modern industries.

The 30SD08-47D Solenoid Directional Valve is a reliable and versatile component that optimizes fluid control in various industrial applications. With its robust construction, precise fluid control, versatility, and space-efficient design, this solenoid valve offers exceptional performance, ensuring efficient and reliable operations. By incorporating the 30SD08-47D Solenoid Directional Valve into fluid control systems, industries can achieve enhanced productivity, accuracy, and system performance. Invest in this advanced solenoid valve to optimize your industrial processes, streamline operations, and achieve success in your industry.

35SD10-20 Solenoid Directional Valve Characteristics:

- Robust Construction: The 35SD10-20 Solenoid Directional Valve is built with a robust and durable design, ensuring long-lasting performance even in demanding environments. Its sturdy construction allows it to withstand high pressures, temperature fluctuations, and harsh conditions, providing consistent and reliable operation.

- Precise Fluid Control: This solenoid valve offers precise control over fluid flow, enabling accurate and efficient regulation of liquids or gases. With its responsive solenoid mechanism, the valve allows for fast and reliable switching between different flow paths, ensuring precise control and minimizing flow disruptions.

- Versatile Functionality: The 35SD10-20 Solenoid Directional Valve is designed to accommodate various applications in different industries. It can be used for direction control, on/off switching, and pressure regulation, providing flexibility and adaptability in fluid control systems.

- Efficient Energy Consumption: This solenoid valve is designed with energy efficiency in mind. It minimizes power consumption during operation, resulting in cost savings and environmental benefits. The valve’s efficient energy usage makes it a sustainable choice for businesses looking to optimize their resource utilization.

35SD10-20 Solenoid Directional Valve Parameter:

| Rated pressure | 241 bar (3500 psi) | |

| Peak flow | 56.8 L/min (15 gpm) ; See performance chart | |

| Fluid | Mineral-based or synthetics with lubricating properties | |

| Fluid temperature range ℃ | -54 to 107 ℃ (Polyurethane seals) | |

| -40 to 100 ℃ (Buna N seals) | ||

| -26 to 204 ℃ (Fluorocarbon seals) | ||

| Viscosity range | 7.4 to 420 mm2/s | |

| Degree of contamination | The minimum pollution level is ISO4406 level 18/16/13, and level 15/13/11 is recommended to prolong the service life | |

| Internal Leakage | ≤ 0.15 mL/min (3 drops /min) @241 bar | |

| Cavity | VC10-2 | |

| Coil Duty Rating | Continuous from 85% to 115% of nominal voltage | |

| Initial Coil Current Draw at 20℃ | E-coil | 1.7A at 12VDC; 0.85A at 24VDC |

| D-coil | 1.67A at 12VDC; 0.83A at 24VDC | |

| Minimum pull-in voltage | 85% of nominal at 241 bar | |

35SD10-20 Solenoid Directional Valve Advantages:

• Continuous-duty rated coil

• Efficient wet-armature construction

• Cartridges are voltage interchangeable

• Optional waterproof E-Coils rated up to IP69K

• Industry common cavity

• Hardened parts for long life and low leakage

Usage Method Of 35SD10-20 Solenoid Directional Valve:

Installation:

- Follow the manufacturer’s instructions for proper installation of the 35SD10-20 Solenoid Directional Valve.

- Ensure correct alignment and connection to the fluid control system, using appropriate fittings and seals for leak-free operation.

Electrical Connections:

- Connect the solenoid valve to the power supply, following the specified voltage and electrical requirements.

- Ensure proper wiring and insulation to ensure safe and reliable electrical operation.

Fluid Flow Direction:

- Determine the desired fluid flow direction based on your application requirements.

- The 35SD10-20 Solenoid Directional Valve provides various ports and positions for inlet, outlet, and exhaust. Consult the product documentation for correct port connections.

Control Signal:

- Connect the control signal, whether electrical or pneumatic, to the solenoid valve to activate its switching mechanism.

- Ensure that the control signal is compatible with the valve’s specifications and operating parameters.

How To Hook Up A Hydraulic Flow Control Valve?

To hook up a hydraulic flow control valve, follow these steps:

- Identify Valve Type: Determine the specific type of flow control valve you are working with. Common types include needle valves, adjustable flow control valves, or pressure-compensated flow control valves. Ensure that the valve is suitable for your application and compatible with your hydraulic system.

- Gather Required Tools and Materials: Collect the necessary tools and materials, including appropriate hydraulic fittings, adapters, hoses, and wrenches.

- Prepare the Hydraulic System: Shut down the hydraulic system and relieve any pressure in the system by activating the relief valve or retracting any hydraulic cylinders. This step is crucial for safety.

- Identify Flow Direction: Identify the flow direction in your hydraulic system. Typically, the flow direction is indicated by arrows on the hydraulic components. Ensure that you understand the correct flow direction before proceeding.

- Locate Installation Point: Determine the optimal location to install the flow control valve in your hydraulic system. Consider factors such as accessibility, proximity to the actuator or hydraulic component, and ease of adjustment.

- Mount the Valve: Securely mount the flow control valve in the chosen location using appropriate brackets or clamps. Ensure the valve is positioned correctly, aligning the inlet and outlet ports with the flow direction.

- Connect the Inlet and Outlet Ports: Attach hydraulic hoses or tubing to the inlet and outlet ports of the flow control valve. Use suitable hydraulic fittings and adapters to create a leak-free connection. Tighten the connections using wrenches to ensure a secure fit, but avoid over-tightening.

- Adjust the Flow Control: Depending on the type of flow control valve, it may have adjustable features such as a needle valve or a flow control knob. Adjust the valve according to your desired flow rate or speed. Refer to the manufacturer’s instructions for specific adjustment procedures.

- Test the System: Once the flow control valve is installed and adjusted, slowly restore hydraulic system pressure. Test the system to ensure that the flow control valve is functioning correctly. Monitor the flow rate or speed of the hydraulic actuator to verify that it is within the desired range.

- Fine-tune and Monitor: Adjust the flow control valve to achieve the desired flow rate or speed. Regularly monitor the hydraulic system for leaks, pressure inconsistencies, or unusual behavior.

Kemampuan & Kapasitas Pabrik:

(1) Perakitan

Kami memiliki platform perakitan penelitian dan pengembangan independen kelas satu. Bengkel produksi silinder hidrolik memiliki empat jalur perakitan silinder pengangkat semi-otomatis dan satu jalur perakitan silinder kemiringan otomatis, dengan kapasitas produksi tahunan yang dirancang sebesar 1 juta keping. Bengkel silinder khusus dilengkapi dengan berbagai spesifikasi sistem perakitan pembersihan semi-otomatis dengan kapasitas produksi tahunan yang dirancang sebesar 200.000 dan dilengkapi dengan peralatan permesinan CNC yang terkenal, pusat permesinan, peralatan khusus pemrosesan silinder presisi tinggi, mesin las robot, mesin pembersih otomatis, mesin perakitan silinder otomatis, dan jalur produksi pengecatan otomatis. Peralatan penting yang ada lebih dari 300 set (set). Alokasi optimal dan penggunaan sumber daya peralatan yang efisien memastikan persyaratan akurasi produk dan memenuhi kebutuhan produk berkualitas tinggi.

(2) Pemesinan

Bengkel permesinan dilengkapi dengan pusat pembubutan rel miring yang disesuaikan, pusat permesinan, mesin pengasah berkecepatan tinggi, robot pengelasan, dan peralatan terkait lainnya, yang dapat menangani pemrosesan tabung silinder dengan diameter bagian dalam maksimum 400mm dan panjang maksimum 6 meter.

(3) Pengelasan

(4) Pengecatan & pelapisan

Dengan jalur pelapisan cat berbasis air otomatis silinder kecil dan menengah, untuk mencapai bongkar muat robot otomatis dan penyemprotan otomatis, kapasitas desain 4000 buah per shift;

Kami juga memiliki lini produksi cat semi-otomatis untuk silinder besar yang ditenagai oleh rantai daya, dengan kapasitas desain 60 kasus per shift.

(5) Pengujian

Kami memiliki fasilitas inspeksi kelas satu dan test bed untuk memastikan bahwa kinerja silinder memenuhi persyaratan.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding gearbox pertanian. Kami telah mengekspor produk kami ke klien di seluruh dunia dan mendapatkan reputasi yang baik karena kualitas produk dan layanan purna jual kami yang unggul. Kami menyambut pelanggan di dalam dan luar negeri untuk menghubungi kami untuk menegosiasikan bisnis, bertukar informasi, dan bekerja sama dengan kami!

Ikuti Tur Pabrik VR Kami:

Ikuti tur ke pabrik VR kami dengan yang berikut ini

Bagaimana Cara Kerja Silinder Hidrolik Forklift?

Aplikasi Silinder Hidraulik: