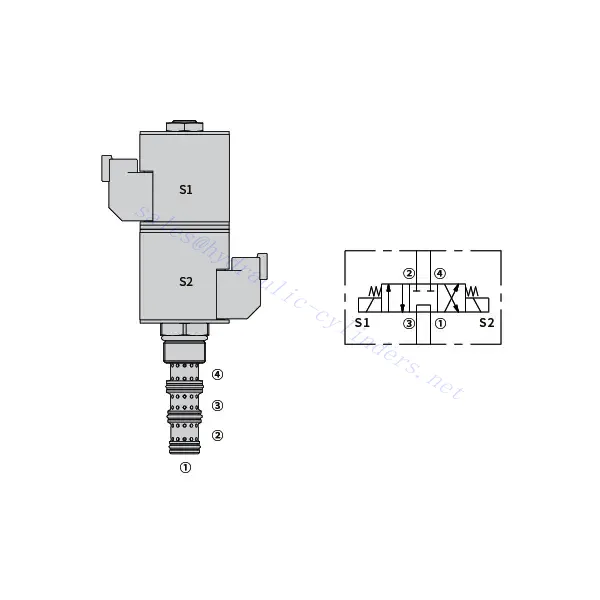

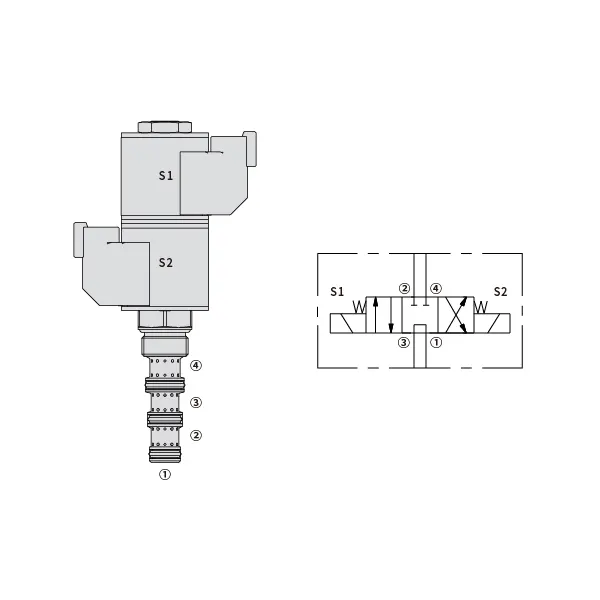

35SD10-47A Solenoid Directional Valve

Sebagai salah satu produsen, pemasok, dan eksportir silinder hidrolik, Kami menawarkan silinder hidrolik dan banyak produk lainnya.

Silakan hubungi kami untuk informasi lebih lanjut.

Surat:sales@hydraulic-cylinders.net

Produsen pemasok eksportir silinder hidrolik.

35SD10-47A Solenoid Directional Valve

The 35SD10-47A solenoid directional valve is a high-performance hydraulic component designed to provide exceptional efficiency and precise control in various applications. With advanced engineering and cutting-edge technology, this valve allows for seamless directional control of hydraulic fluid, enabling reliable operation in various industries. From industrial machinery to mobile equipment, the 35SD10-47A solenoid directional valve is the trusted solution for optimizing hydraulic systems.

The 35SD10-47A solenoid directional valve offers exceptional hydraulic systems efficiency, control, and durability. Its precise directional control capabilities, robust construction, and easy installation make it an excellent choice for various applications. By following the recommended maintenance practices, you can ensure optimal performance and extend the lifespan of this valve. Invest in the 35SD10-47A solenoid directional valve today and experience enhanced efficiency and control in your hydraulic systems.

35SD10-47A Solenoid Directional Valve Characteristics:

- Robust Construction: The 35SD10-47A solenoid directional valve is built to withstand demanding environments. Constructed from high-quality materials, it offers exceptional durability and longevity, ensuring reliable performance even in harsh conditions.

- High Flow Capacity: This valve boasts a high flow capacity, enabling efficient and rapid movement of hydraulic fluid. It facilitates quick response times and enhances the overall productivity of hydraulic systems.

- Precise Control: The 35SD10-47A solenoid directional valve allows precise control over the direction of hydraulic flow. It offers excellent accuracy and repeatability, ensuring your hydraulic system operates strictly as intended.

- Low Pressure Drop: With its optimized design, this valve minimizes pressure drop, maximizing the efficiency of your hydraulic system. It allows for smooth fluid flow without unnecessary energy losses.

35SD10-47A Solenoid Directional Valve Parameter:

| Rated pressure | 240 bar (3500 psi) | |

| Peak flow | 19 L/min (5 gpm) | |

| Fluid | Mineral-based or synthetics with lubricating properties | |

| Fluid temperature range ℃ | -54 to 107 ℃ (Polyurethane seals) | |

| -40 to 100 ℃ (Buna N seals) | ||

| -26 to 204 ℃ (Fluorocarbon seals) | ||

| Viscosity range | 7.4 to 420 mm2/s | |

| Degree of contamination | The minimum pollution level is ISO4406 level 18/16/13, and level 15/13/11 is recommended to prolong the service life | |

| Internal Leakage | ≤ 328 mL/min@240 bar | |

| Cavity | VC10-4 | |

| Coil Duty Rating | Continuous from 85% to 115% of nominal voltage | |

| Initial Coil Current Draw at 20℃ | E-coil | 1.7A at 12VDC; 0.85A at 24VDC |

| D-coil | 1.67A at 12VDC; 0.83A at 24VDC | |

| Minimum pull-in voltage | 85% of nominal at 207 bar | |

35SD10-47A Solenoid Directional Valve Advantages:

• Continuous-duty rated coil

• Cartridges are voltage interchangeable

• Optional waterproof E-Coils rated up to IP69K

• Efficient wet-armature construction

• Industry common cavity

• Hardened parts for long life

Maintenance Of 35SD10-47A Solenoid Directional Valve:

Using the 35SD10-47A Solenoid Directional Valve is straightforward and user-friendly. Here’s a step-by-step guide to get you started:

- System Preparation: Ensure the hydraulic system is appropriately set up and all necessary components are in place.

- Mounting: Install the 35SD10-47A solenoid directional valve in the desired location within the hydraulic system and secure it tightly using appropriate mounting brackets or fasteners.

- Plumbing Connections: Connect the hydraulic lines to the designated ports on the valve. Ensure proper alignment and tighten the connections to prevent any leaks.

- Electrical Connections: Connect the solenoid valve to the electrical power supply. Follow the wiring diagram provided with the valve to connect the wires and ensure safe operation correctly.

- Test and Adjust: Once the valve is installed and connected, test its functionality by activating the solenoid and observing the directional control of the hydraulic fluid. Make any necessary adjustments to ensure proper operation.

How To Remove A Moen Shower Valve Cartridge?

Removing a Moen shower valve cartridge is a crucial step when replacing or repairing your shower valve. Here’s a step-by-step guide to help you remove the cartridge:

- Gather the Required Tools: Before starting, gather the necessary tools, including an adjustable wrench, pliers, a cartridge puller (if needed), and a screwdriver.

- Turn Off the Water Supply: Locate the main water shut-off valve for your house and turn it off to stop the water flow to the shower. If you have a dedicated shut-off valve for the shower, you can use that instead.

- Remove the Handle and Trim: Remove the handle by locating the set screw or screw cover on the handle and using a screwdriver or Allen wrench to loosen and remove it. Once the screw is removed, pull the handle off. Next, remove the trim plate or escutcheon surrounding the valve using a screwdriver.

- Identify the Retaining Clip: Behind the trim plate, you will find a retaining clip or pin that holds the cartridge in place. This clip might be circular or horseshoe-shaped, depending on the Moen shower valve model.

- Remove the Retaining Clip: Use pliers to grip the retaining clip and carefully pull it out. Be cautious as the clip may spring out when released. Set the clip aside for reinstallation later.

- Extract the Cartridge: With the retaining clip removed, the cartridge is ready to be taken out. Grasp the cartridge firmly with pliers or use a cartridge puller if necessary. Slowly and steadily pull the cartridge straight out of the valve body.

- Clean and Inspect: Once the cartridge is removed, inspect it for any signs of damage or wear. Also, take a moment to clean the valve body and remove any debris or buildup that may affect the new cartridge’s performance.

Kemampuan & Kapasitas Pabrik:

(1) Perakitan

Kami memiliki platform perakitan penelitian dan pengembangan independen kelas satu. Bengkel produksi silinder hidrolik memiliki empat jalur perakitan silinder pengangkat semi-otomatis dan satu jalur perakitan silinder kemiringan otomatis, dengan kapasitas produksi tahunan yang dirancang sebesar 1 juta keping. Bengkel silinder khusus dilengkapi dengan berbagai spesifikasi sistem perakitan pembersihan semi-otomatis dengan kapasitas produksi tahunan yang dirancang sebesar 200.000 dan dilengkapi dengan peralatan permesinan CNC yang terkenal, pusat permesinan, peralatan khusus pemrosesan silinder presisi tinggi, mesin las robot, mesin pembersih otomatis, mesin perakitan silinder otomatis, dan jalur produksi pengecatan otomatis. Peralatan penting yang ada lebih dari 300 set (set). Alokasi optimal dan penggunaan sumber daya peralatan yang efisien memastikan persyaratan akurasi produk dan memenuhi kebutuhan produk berkualitas tinggi.

(2) Pemesinan

Bengkel permesinan dilengkapi dengan pusat pembubutan rel miring yang disesuaikan, pusat permesinan, mesin pengasah berkecepatan tinggi, robot pengelasan, dan peralatan terkait lainnya, yang dapat menangani pemrosesan tabung silinder dengan diameter bagian dalam maksimum 400mm dan panjang maksimum 6 meter.

(3) Pengelasan

(4) Pengecatan & pelapisan

Dengan jalur pelapisan cat berbasis air otomatis silinder kecil dan menengah, untuk mencapai bongkar muat robot otomatis dan penyemprotan otomatis, kapasitas desain 4000 buah per shift;

Kami juga memiliki lini produksi cat semi-otomatis untuk silinder besar yang ditenagai oleh rantai daya, dengan kapasitas desain 60 kasus per shift.

(5) Pengujian

Kami memiliki fasilitas inspeksi kelas satu dan test bed untuk memastikan bahwa kinerja silinder memenuhi persyaratan.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding gearbox pertanian. Kami telah mengekspor produk kami ke klien di seluruh dunia dan mendapatkan reputasi yang baik karena kualitas produk dan layanan purna jual kami yang unggul. Kami menyambut pelanggan di dalam dan luar negeri untuk menghubungi kami untuk menegosiasikan bisnis, bertukar informasi, dan bekerja sama dengan kami!

Ikuti Tur Pabrik VR Kami:

Ikuti tur ke pabrik VR kami dengan yang berikut ini

Aplikasi Silinder Hidraulik: