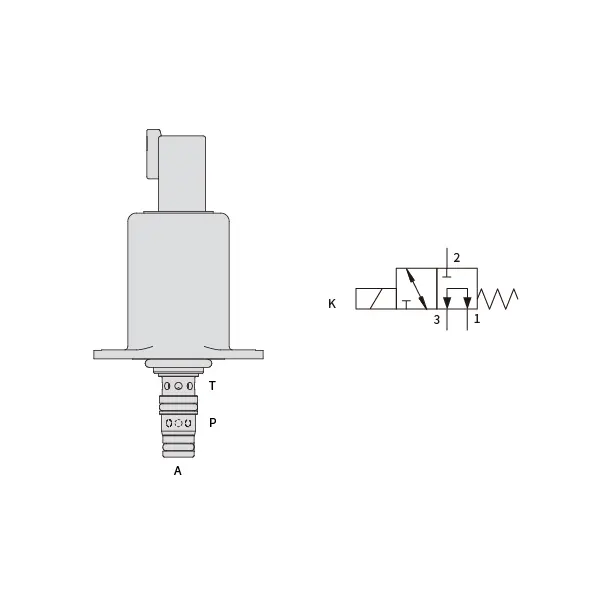

SDCV-04 Electromagnetic Directioanl Valve

Sebagai salah satu produsen, pemasok, dan eksportir silinder hidrolik, Kami menawarkan silinder hidrolik dan banyak produk lainnya.

Silakan hubungi kami untuk informasi lebih lanjut.

Surat:sales@hydraulic-cylinders.net

Produsen pemasok eksportir silinder hidrolik.

SDCV-04 Electromagnetic Directioanl Valve

The sdcv-04 electromagnetic directional valve is an exceptional product designed to optimize fluid control systems with its advanced features and superior performance. This valve provides precise control over the flow direction of fluids, making it an ideal choice for a wide range of industrial applications. Whether in manufacturing, automation, or other fluid control processes, the sdcv-04 electromagnetic directional valve delivers reliable and efficient fluid control.

The sdcv-04 electromagnetic directional valve offers precise fluid control capabilities, ensuring optimal performance in various industrial applications. With its robust construction, precise control, fast response time, and compact design, this valve provides reliability and efficiency in fluid control systems. By following the correct usage method and implementing regular maintenance practices, you can maximize the potential of the sdcv-04 electromagnetic directional valve, enhancing fluid control and productivity in your operations. Upgrade your fluid control system today with the precision and reliability of the sdcv-04 electromagnetic directional valve.

KSE66-C0820 Solenoid Directional Valve Characteristics:

- Robust Construction: The SDCV-04 Electromagnetic Directional Valve is built with high-quality materials and ensures durability and longevity even under demanding operating conditions. It can withstand high pressures and harsh environments, delivering consistent performance over an extended period.

- Precise Fluid Control: This valve offers exceptional precision in controlling the direction of fluid flow. With accurate adjustments, it enables optimal performance and efficiency in various applications. The ability to precisely direct fluid flow enhances overall system functionality and productivity.

- Fast Response Time: The SDCV-04 Electromagnetic Directional Valve boasts a rapid response time, allowing for quick and reliable switching between different flow paths. This feature is precious in time-sensitive applications where immediate changes in fluid direction are critical.

- Compact and Space-Saving Design: The valve’s compact size and space-saving design make it highly versatile and easy to integrate into different fluid control systems. Its streamlined structure ensures efficient use of space without compromising performance.

KSE66-C0820 Solenoid Directional Valve Parameter:

| General | ||

| Weight | 0.203g | |

| Installation orientation | optional,recommend installing vertically with the connector plug down. | |

| MTTFd value | 150 year | |

| Ambient temperature range | -30~80℃ | |

| Hydraulic | ||

| Max.operating pressure | PP = 50bar | |

| Max. back pressure | PT = 30bar | |

| Degree of contamination | Maximum permissible degree of fluid contamination: Class 9. NAS 1638 or 20/18/15 , ISO4406 | |

| Fluid | Mineral oil (DIN 51524) | |

| Fluid temperature range | 30~105℃ | |

| Leakage | <100mL/min(power loss) | |

| <100mL/min(power on) | ||

| Filtration accuracy | 200μm(P 口) | |

| Electrical | ||

| Operating pressure(Ampilfier) | 12V | 24V |

| Coil resistance(20℃) | 9 Ω | 34 Ω |

| Connector form | DT04-2P Deutsch(Deutsch) | |

| Degree of protection | IP6K6/IPX9K | |

| Response Time | Commutation time<60ms | |

| Response Time<100ms | ||

KSE66-C0820 Solenoid Directional Valve Advantages:

• Quick response

• Compact size

• Wet type DC solenoid

Usage Method Of KSE66-C0820 Solenoid Directional Valve:

To effectively utilize the SDCV-04 Electromagnetic Directional Valve, follow these step-by-step instructions:

- System Assessment: Evaluate the fluid control system requirements, including pressure ratings, flow rates, and directional control needs. Ensure that the SDCV-04 Electromagnetic Directional Valve is compatible with your specific application.

- Mounting and Connection: Select the appropriate mounting method based on your system configuration and available space. Install the valve securely, aligning it with the fluid lines. Connect the valve using compatible fittings and connectors, ensuring tight and leak-free connections.

- Electrical Connection: Connect the electromagnetic coil of the valve to the appropriate power supply, following the manufacturer’s guidelines. Ensure correct wiring and observe safety precautions during the electrical connection process.

- Testing and Calibration: Gradually introduce fluid flow into the system and monitor the valve’s performance. Test different operating conditions, such as pressure and flow variations, and calibrate the valve settings as needed to achieve optimal control and system functionality.

What Does A Shower Valve Cartridge Do?

A shower valve cartridge is a crucial component of a shower valve system that controls the flow and temperature of water. It is responsible for regulating the mixing of hot and cold water to achieve the desired water temperature and controlling the volume of water that flows through the showerhead.

Here are the primary functions of a shower valve cartridge:

- Temperature Control: The shower valve cartridge allows you to adjust the water temperature by controlling the ratio of hot and cold water that mixes within the valve. By turning the shower handle or lever, the cartridge moves to increase or decrease the flow of hot and cold water, resulting in the desired temperature.

- Volume Control: In addition to temperature control, the shower valve cartridge also manages the volume or flow rate of water. By adjusting the handle or lever, the cartridge opens or restricts the water flow, allowing you to achieve the desired water pressure for a comfortable shower experience.

- Diverter Functionality: Some shower valve cartridges also include a diverter function. This feature allows you to divert water flow between different shower outlets, such as a showerhead, hand shower, or body jets. By activating the diverter, the cartridge redirects the water flow to the desired outlet, providing flexibility in showering options.

- Shut-off Capability: The shower valve cartridge enables complete shut-off of water flow when the shower is not in use. By turning the handle or lever to the off position, the cartridge closes the water supply, preventing any water from flowing through the showerhead.

Kemampuan & Kapasitas Pabrik:

(1) Perakitan

Kami memiliki platform perakitan penelitian dan pengembangan independen kelas satu. Bengkel produksi silinder hidrolik memiliki empat jalur perakitan silinder pengangkat semi-otomatis dan satu jalur perakitan silinder kemiringan otomatis, dengan kapasitas produksi tahunan yang dirancang sebesar 1 juta keping. Bengkel silinder khusus dilengkapi dengan berbagai spesifikasi sistem perakitan pembersihan semi-otomatis dengan kapasitas produksi tahunan yang dirancang sebesar 200.000 dan dilengkapi dengan peralatan permesinan CNC yang terkenal, pusat permesinan, peralatan khusus pemrosesan silinder presisi tinggi, mesin las robot, mesin pembersih otomatis, mesin perakitan silinder otomatis, dan jalur produksi pengecatan otomatis. Peralatan penting yang ada lebih dari 300 set (set). Alokasi optimal dan penggunaan sumber daya peralatan yang efisien memastikan persyaratan akurasi produk dan memenuhi kebutuhan produk berkualitas tinggi.

(2) Pemesinan

Bengkel permesinan dilengkapi dengan pusat pembubutan rel miring yang disesuaikan, pusat permesinan, mesin pengasah berkecepatan tinggi, robot pengelasan, dan peralatan terkait lainnya, yang dapat menangani pemrosesan tabung silinder dengan diameter bagian dalam maksimum 400mm dan panjang maksimum 6 meter.

(3) Pengelasan

(4) Pengecatan & pelapisan

Dengan jalur pelapisan cat berbasis air otomatis silinder kecil dan menengah, untuk mencapai bongkar muat robot otomatis dan penyemprotan otomatis, kapasitas desain 4000 buah per shift;

Kami juga memiliki lini produksi cat semi-otomatis untuk silinder besar yang ditenagai oleh rantai daya, dengan kapasitas desain 60 kasus per shift.

(5) Pengujian

Kami memiliki fasilitas inspeksi kelas satu dan test bed untuk memastikan bahwa kinerja silinder memenuhi persyaratan.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding gearbox pertanian. Kami telah mengekspor produk kami ke klien di seluruh dunia dan mendapatkan reputasi yang baik karena kualitas produk dan layanan purna jual kami yang unggul. Kami menyambut pelanggan di dalam dan luar negeri untuk menghubungi kami untuk menegosiasikan bisnis, bertukar informasi, dan bekerja sama dengan kami!

Ikuti Tur Pabrik VR Kami:

Ikuti tur ke pabrik VR kami dengan yang berikut ini

Aplikasi Silinder Hidraulik: