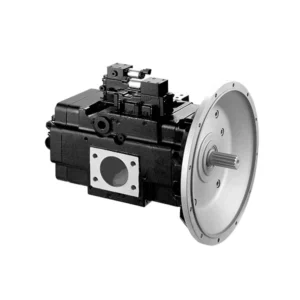

V90N-DT Series Axial Piston Variable Displacement Double Hydraulic Pump

Sebagai salah satu produsen, pemasok, dan eksportir silinder hidrolik, Kami menawarkan silinder hidrolik dan banyak produk lainnya.

Silakan hubungi kami untuk informasi lebih lanjut.

Surat:sales@hydraulic-cylinders.net

Produsen pemasok eksportir silinder hidrolik.

V90N-DT Series Axial Piston Variable Displacement Double Hydraulic Pump

The V90N-DT series axial piston variable displacement double hydraulic pump is a game-changer in hydraulic systems. With its exceptional versatility, efficiency, and reliability, this pump is indispensable in various industrial applications. This comprehensive article will explore the key characteristics, usage methods, and maintenance guidelines for the v90n-dt series axial piston variable displacement double hydraulic pump.

The V90N-DT series axial piston variable displacement double hydraulic pump is a versatile and efficient solution for hydraulic systems. With its dual pump configuration, variable displacement technology, and compact design, this pump delivers exceptional performance across various industrial applications. By following the recommended usage methods and adhering to regular maintenance practices, the v90n-dt series pump will continue to provide outstanding performance, contributing to the success of hydraulic systems. Embrace the power of versatility and efficiency with the v90n-dt series axial piston variable displacement double hydraulic pump and unlock the full potential of your hydraulic system.

V90N-DT Series Axial Piston Variable Displacement Double Hydraulic Pump Key Characteristics:

- Dual Pump Configuration: The V90N-DT series features a dual hydraulic pump configuration, combining two pumps in a single unit. This design allows for efficient power distribution and enhanced performance, making it ideal for applications that require multiple hydraulic functions or simultaneous operations.

- Variable Displacement Technology: Equipped with advanced variable displacement technology, the V90N-DT series pump enables precise adjustment of the output volume for each hydraulic pump. This feature optimizes energy consumption, reduces heat generation, and enhances overall system efficiency.

- High Pressure Capability: With a robust axial piston design, the V90N-DT series hydraulic pump delivers exceptional performance even under high-pressure conditions. It ensures reliable operation and efficient power transmission, making it suitable for demanding industrial applications.

- Compact and Space-Saving Design: The pump’s compact size and space-saving design allow for easy integration into hydraulic systems with limited space. The dual hydraulic pump configuration eliminates the need for separate pumps, resulting in a more streamlined and efficient system layout.

- Wide Range of Applications: The V90N-DT series hydraulic pump is highly versatile and can be used in various industries, including construction, material handling, agriculture, and more. Its adaptability to different working conditions and requirements makes it a valuable asset for diverse applications.

V90N-DT Series Axial Piston Variable Displacement Double Hydraulic Pump Parameter:

| Size | Displacement cc/rev | Pressure bar | Rotation speed r/min | ||

| Rated | Peak | Max for self-priming*1 | Max*2 | ||

| V90N75DT | 75*2 | 350 | 400 | 2450 | 3000 |

| V90N130DT | 130*2 | 380 | 420 | 2200 | 2500 |

| V90N180DT | 180*2 | 380 | 420 | 2000 | 2400 |

| V90N280DT | 280*2 | 380 | 420 | 1800 | 2100 |

V90N-DT Series Axial Piston Variable Displacement Double Hydraulic Pump Advantages:

• Applied in high-pressure open-circuit hydraulic systems

• Multiple control methods

• High efficiency, long life

• Small installation length

• High volume efficiency

• Low noise

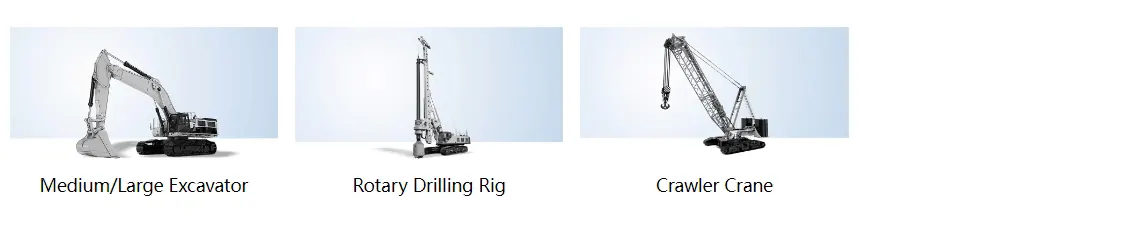

V90N-DT Series Axial Piston Variable Displacement Double Hydraulic Pump Application:

Usage Method Of HP3V Series Axial Piston Variable Displacement Hydraulic Pump:

- Pump Installation: Select an appropriate location within the hydraulic system to install the V90N-DT series axial piston variable displacement double pump. Ensure proper alignment and securely attach the pump to the system’s structure using suitable mounting brackets or accessories.

- Integration with Hydraulic System: Connect the pump to the hydraulic system using compatible hoses, fittings, and valves. Ensure all connections are secure, leak-free, and properly tightened to guarantee optimal hydraulic performance.

- Fluid Compatibility: Verify that the hydraulic fluid used in the system is compatible with the V90N-DT series pump. Refer to the manufacturer’s recommendations for the appropriate fluid type, viscosity, and temperature range. Regularly monitor and maintain the hydraulic fluid to ensure proper pump operation and longevity.

- Operational Parameters: Familiarize yourself with the pump’s control options and adjust the operating parameters according to the specific requirements of the hydraulic system. Monitor and change the pump’s displacement settings to optimize performance and energy efficiency.

How To Bleed Hydraulic Cylinder?

Bleeding a hydraulic cylinder is a process used to remove air or gas trapped within the system and ensure proper functioning. Here’s a step-by-step guide on how to bleed a hydraulic cylinder:

- Safety Precautions:

- Ensure the hydraulic system is depressurized and turned off.

- Wear appropriate personal protective equipment, such as gloves and safety glasses.

- Locate Bleeder Valve:

- Identify the bleeder valve on the hydraulic cylinder. It is typically located near the highest point of the cylinder or on the end cap.

- Prepare Tools:

- Gather the necessary tools, including a wrench or socket that fits the bleeder valve.

- Position a Container:

- Place a suitable container or absorbent material beneath the bleeder valve to catch any fluid that may be released during the bleeding process.

- Open Bleeder Valve:

- Slowly and carefully open the bleeder valve counterclockwise using the wrench or socket. This allows air or gas to escape from the cylinder.

- Monitor Fluid Flow:

- Keep an eye on the fluid flow from the bleeder valve. Initially, air or gas may be released, followed by a steady stream of hydraulic fluid. Allow the fluid to flow until all air bubbles are eliminated and only fluid is being expelled.

- Close Bleeder Valve:

- Once only fluid is flowing consistently, close the bleeder valve clockwise. Ensure it is tightened securely, but avoid over-tightening to prevent damage.

- Check Fluid Level:

- Verify the hydraulic fluid level in the system reservoir. If necessary, add fluid to maintain the recommended level.

- Test Cylinder Operation:

- Turn on the hydraulic system and operate the cylinder through its full range of motion. Observe for any abnormalities or irregularities in its movement.

- Repeat if Necessary:

- If there are still signs of air in the system or if the cylinder’s operation is not smooth, repeat the bleeding process. Open the bleeder valve again and allow more fluid to flow until all air is purged.

- Final Check and Maintenance:

- Conduct a final inspection of the hydraulic system for any leaks, proper fluid level, and smooth operation. Address any issues as needed.

- Implement a regular maintenance schedule for the hydraulic system, including periodic checks for air accumulation and bleeding if necessary.

Kemampuan & Kapasitas Pabrik:

(1) Perakitan

Kami memiliki platform perakitan penelitian dan pengembangan independen kelas satu. Bengkel produksi silinder hidrolik memiliki empat jalur perakitan silinder pengangkat semi-otomatis dan satu jalur perakitan silinder kemiringan otomatis, dengan kapasitas produksi tahunan yang dirancang sebesar 1 juta keping. Bengkel silinder khusus dilengkapi dengan berbagai spesifikasi sistem perakitan pembersihan semi-otomatis dengan kapasitas produksi tahunan yang dirancang sebesar 200.000 dan dilengkapi dengan peralatan permesinan CNC yang terkenal, pusat permesinan, peralatan khusus pemrosesan silinder presisi tinggi, mesin las robot, mesin pembersih otomatis, mesin perakitan silinder otomatis, dan jalur produksi pengecatan otomatis. Peralatan penting yang ada lebih dari 300 set (set). Alokasi optimal dan penggunaan sumber daya peralatan yang efisien memastikan persyaratan akurasi produk dan memenuhi kebutuhan produk berkualitas tinggi.

(2) Pemesinan

Bengkel permesinan dilengkapi dengan pusat pembubutan rel miring yang disesuaikan, pusat permesinan, mesin pengasah berkecepatan tinggi, robot pengelasan, dan peralatan terkait lainnya, yang dapat menangani pemrosesan tabung silinder dengan diameter bagian dalam maksimum 400mm dan panjang maksimum 6 meter.

(3) Pengelasan

(4) Pengecatan & pelapisan

Dengan jalur pelapisan cat berbasis air otomatis silinder kecil dan menengah, untuk mencapai bongkar muat robot otomatis dan penyemprotan otomatis, kapasitas desain 4000 buah per shift;

Kami juga memiliki lini produksi cat semi-otomatis untuk silinder besar yang ditenagai oleh rantai daya, dengan kapasitas desain 60 kasus per shift.

(5) Pengujian

Kami memiliki fasilitas inspeksi kelas satu dan test bed untuk memastikan bahwa kinerja silinder memenuhi persyaratan.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding gearbox pertanian. Kami telah mengekspor produk kami ke klien di seluruh dunia dan mendapatkan reputasi yang baik karena kualitas produk dan layanan purna jual kami yang unggul. Kami menyambut pelanggan di dalam dan luar negeri untuk menghubungi kami untuk menegosiasikan bisnis, bertukar informasi, dan bekerja sama dengan kami!

Ikuti Tur Pabrik VR Kami:

Ikuti tur ke pabrik VR kami dengan yang berikut ini

Aplikasi Silinder Hidraulik: