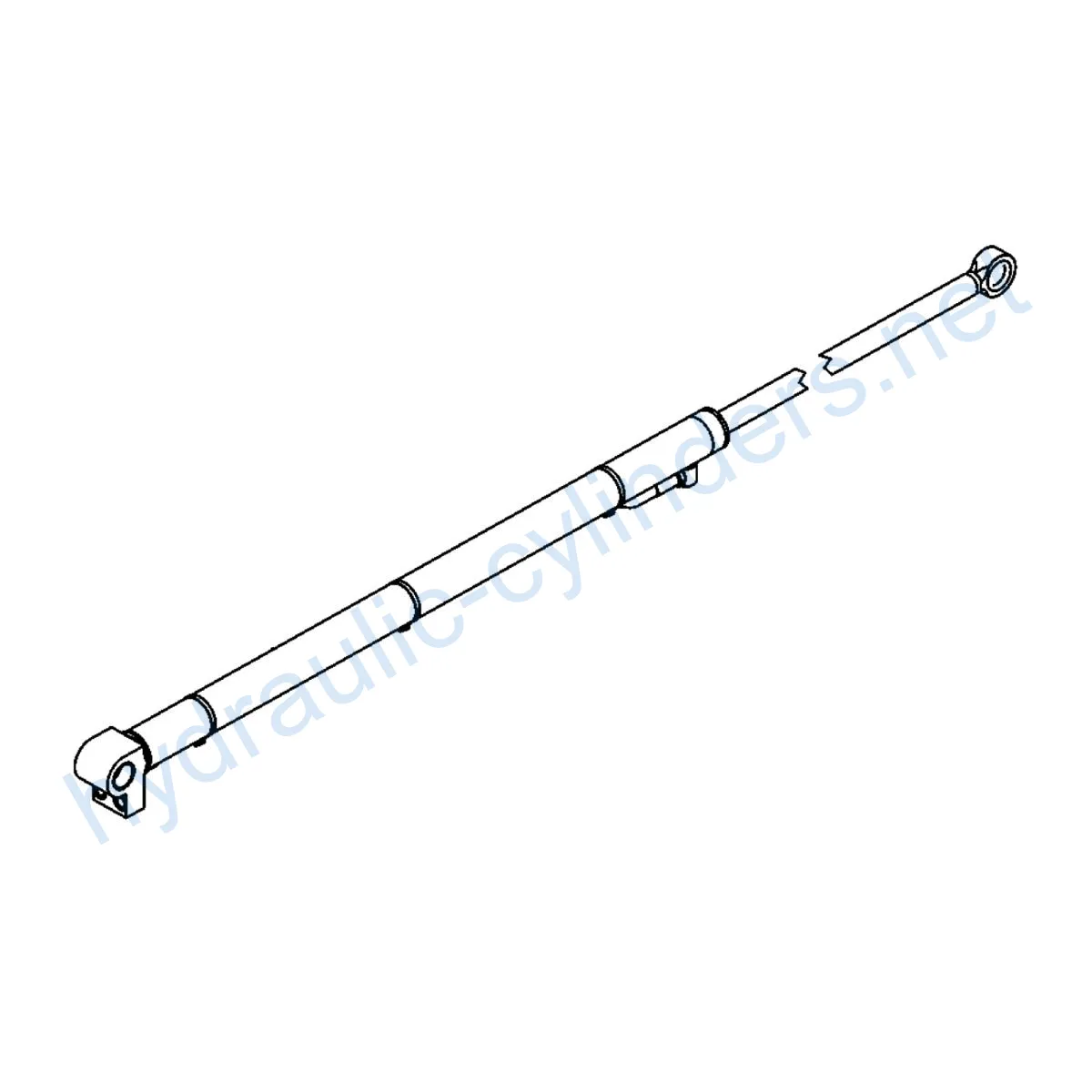

Replacement Of F072504 Hydraulic Cylinder

유압 실린더 제조업체, 공급 업체 및 기계 제품 수출 업체 중 하나로서 유압 실린더 및 기타 여러 제품을 제공합니다.

자세한 내용은 당사에 문의해 주세요.

메일:sales@hydraulic-cylinders.net

유압 실린더 제조업체 공급 업체 수출.

Replacement Of F072504 Hydraulic Cylinder

The Replacement Of F072504 Hydraulic Cylinder is a crucial component in the hydraulic system of the 1270E and 1270G CH7 models. We offer a high-quality replacement that matches the specifications of the original product.

Specifications and Models

The Replacement Of F072504 Hydraulic Cylinder weighs 85 lb and measures 3.7 inches in height, 5.5 inches in width, and 63.9 inches in length. It is designed specifically for the 1270E and 1270G CH7 models.

특징

- Improved equipment performance: Replacing damaged or worn hydraulic cylinders can restore the equipment’s normal operating capabilities, ensuring its performance in various applications.

- Enhanced safety: Regularly replacing hydraulic cylinders can reduce safety hazards caused by cylinder malfunctions, ensuring the safety of operators and equipment.

- Overload protection: New cylinder designs typically consider better overload protection mechanisms, improving safety.

- Quick installation: Modern hydraulic cylinder designs typically consider ease of installation and replacement, reducing downtime.

- Standardized components: Many hydraulic cylinders are standardized products, making it easy to obtain replacement parts on the market.

Our replacement product is manufactured with the same high standards as the original product, ensuring perfect compatibility and optimal performance.

Applications

The Replacement Of F072504 Hydraulic Cylinder can be used in a variety of heavy-duty machinery. Here are a few examples:

- Excavator: The hydraulic cylinder in the arm or bucket of an excavator may be damaged due to long-term use or overload and needs replacement to restore normal operation.

- Crane: The crane’s boom hydraulic cylinder is prone to wear during frequent lifting and lowering processes and requires regular replacement to ensure safety.

- Tractor: The front-end loader hydraulic cylinder of a tractor may experience leaks or performance degradation due to continuous lifting and tilting operations and requires replacement.

- Harvester: During harvesting, the hydraulic system is subjected to high pressure, and the cylinder may be damaged due to fatigue, requiring timely replacement to maintain work efficiency.

- Automated production line: Hydraulic cylinders are used to control robot arms and other automated equipment. If the cylinder fails, it can affect production efficiency and requires immediate replacement.

- Die-casting machine: In high-pressure and high-temperature environments, hydraulic cylinders may experience performance degradation, and regular replacement ensures product quality.

- Mining equipment: Hydraulic cylinders are used to lift and move heavy objects in mining equipment. Due to the harsh working environment, regular inspections and replacements are needed to avoid equipment failures.

- Bulldozer: The wear of the hydraulic cylinder on the bulldozer’s push arm can cause a decrease in pushing capacity, and timely replacement is required to maintain operating efficiency.

Maintenance

Proper maintenance is essential for the longevity and reliable operation of the Replacement Of F072504 Hydraulic Cylinder. Here are some recommended maintenance tasks:

Regular Inspection

It is recommended to inspect the hydraulic cylinder regularly for any signs of wear or damage. Early detection of issues can prevent further damage and downtime.

Lubrication

Proper lubrication is crucial for the smooth operation of the hydraulic cylinder. It is recommended to use the appropriate lubricant and apply it regularly.

Seal Replacement and Calibration Check

Seals can wear out over time, leading to leaks or performance degradation. It is recommended to replace the seals and check the calibration regularly to ensure optimal performance.

During installation, it is important to provide proper alignment guidance and suggest the use of appropriate installation brackets to secure the cylinder. We also recommend following the recommended inspection, repair, and replacement procedures and providing replacement parts and rebuilding services to extend the life of your hydraulic cylinders.

Safety and Environmental Considerations

When using hydraulic cylinders, safety measures are essential to prevent accidents and injuries. It is recommended to follow all safety guidelines and use appropriate personal protective equipment.

The hydraulic fluid used in the system must be disposed of properly to prevent environmental pollution. It is recommended to follow all local regulations and guidelines for the disposal of hydraulic fluids.

Troubleshooting and Common Issues

Common issues that can arise with hydraulic cylinders include leaks, insufficient pressure, and erratic movement. If you experience any of these issues, here are some tips for troubleshooting and resolving the problem:

- Check for any visible damage or wear on the cylinder.

- Ensure that the hydraulic fluid is at the recommended level and is free of contaminants.

- Inspect the seals and replace them if necessary.

- Check the calibration of the cylinder and recalibrate if needed.

Preventive measures can help avoid potential problems. It is recommended to schedule regular inspections and maintenance of the hydraulic system to keep it in optimal condition.

Design Considerations and Selection Criteria

When selecting a hydraulic cylinder, it is essential to consider its load-bearing capacity, sealing, durability, safety, and ease of maintenance. Here are some design considerations to keep in mind:

- The cylinder should be able to support the maximum load that it will be subjected to in the application.

- The seal material should be wear-resistant and able to withstand the operating conditions.

- The cylinder should be durable and able to withstand the stresses of the application.

- Safety features such as overload protection should be considered to prevent accidents and injuries.

- The cylinder should be easy to maintain and repair to minimize downtime.

Proper sealing and lubrication are also essential for the optimal performance of the hydraulic cylinder. It is recommended to use high-quality seals made of wear-resistant materials and to apply the appropriate lubricant regularly.

Company Introduction

We are a leading manufacturer and wholesale distributor of hydraulic cylinders, offering a wide range of products that meet the needs of domestic and international markets.

Professionalism

Our team of experts is dedicated to providing high-quality products and services to our customers. We have years of experience in the industry and are committed to staying up-to-date with the latest technologies and trends.

International Certification

Our products are certified to meet international standards, ensuring their safety and reliability. We follow strict quality control procedures to maintain our high standards of excellence.

Customization Services

We offer customized solutions to meet the unique needs of our customers. Our team of engineers and designers can create custom designs to meet specific requirements.

Production Equipment

We use state-of-the-art production equipment and technology to manufacture our products. Our modern facilities and equipment enable us to produce high-quality hydraulic cylinders efficiently.

After-Sales Service

We provide comprehensive after-sales services to our customers, including maintenance, repair, and replacement services. We are committed to ensuring our customers’ satisfaction and are always available to answer any questions or concerns.

Author: lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: