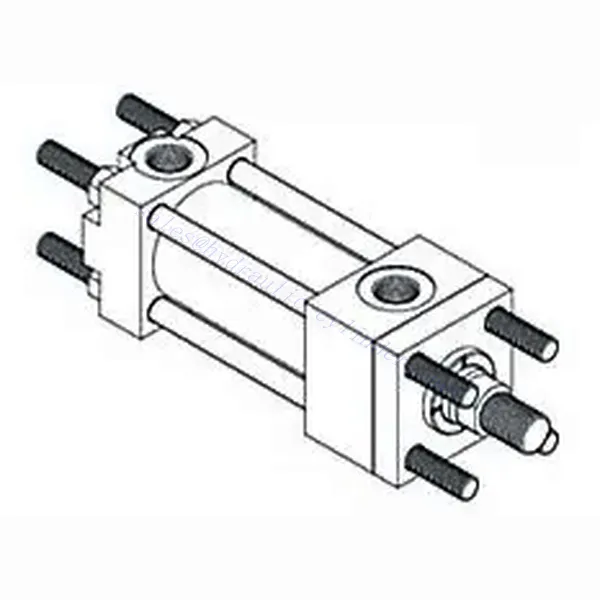

TD 타입 4로드 유압 실린더

The Type TD four rod hydraulic cylinder is a high-performance hydraulic element designed to meet the needs of various industrial applications. With its innovative design, precision engineering, and superior durability, this fou rod hydraulic cylinder offers exceptional functionality and efficiency.

Essential Characteristics Of Four Rod Hydraulic Cylinder:

The TD type four rod hydraulic cylinder possesses several noteworthy features that set it apart in the hydraulic industry:

Enhanced Stability and Load-Bearing Capacity:

- The four-rod configuration provides exceptional stability, distributing the load evenly across the cylinder. This design minimizes deflection, ensuring consistent performance even under heavy loads and challenging conditions.

- The increased load-bearing capacity of the cylinder makes it ideally suited for applications involving high forces and substantial loads.

Precise Control and Positioning:

- The four-rod design of the TD cylinder enables precise control and positioning of the piston rod. This feature ensures accurate movement and alignment of loads, allowing specific and synchronous operations.

- The precise control provided by the cylinder makes it ideal for applications that require exact motion control, such as robotics, material handling, and automation systems.

Durability and Longevity:

- TD four rod hydraulic cylinders are built to withstand harsh environments and heavy use. It is made of high quality materials that provide superior strength, durability, wear resistance, and corrosion resistance.

- The cylinder’s rugged construction ensures longevity and reliable performance, reducing downtime and maintenance costs.

TD Type Four Rod Hydraulic Cylinder Parameter:

TD 타입 4로드 유압 실린더 사용 방법:

The type TD four rod hydraulic cylinder is designed for direct integration into various hydraulic systems. The following are general guidelines for using cylinders effectively:

Mounting and Connection:

- Ensure proper alignment and secure cylinder mounting to the equipment or machinery using suitable bolts or fasteners.

- Connect the hydraulic line to the inlet and outlet ports of the cylinder to ensure a safe connection and no leakage. Use appropriate fittings, seals and thread types as recommended by the manufacturer.

Hydraulic Control:

- Activate the hydraulic system that powers the cylinder by operating the associated hydraulic pump or control valve.

- The hydraulic flow and pressure are adjusted by the control valve to control the movement of the cylinder. This allows precise positioning and operation of the hydraulic cylinder.

TD 타입 4로드 유압 실린더 Maintenance:

Proper TD type four rod hydraulic cylinder maintenance ensures optimal performance and extends lifespan. Consider the following maintenance tips:

Regular Inspection:

- Check the cylinder regularly for leaks, damage, or excessive wear. Pay attention to seals, tie rods, and mounting parts.

- Replace any worn or damaged parts promptly to prevent further problems and ensure optimal performance.

Lubrication:

- Lubricate intervals as recommended by the manufacturer. Apply high quality hydraulic oil or grease to rods, seals and other moving parts.

- Proper lubrication can reduce friction and wear, and ensure smooth operation of the hydraulic cylinder.

Cleanliness:

- Keep four rod hydraulic cylinders and their surroundings clean and free of dirt, debris, or contaminants that affect performance.

- Use a mild cleaner and a soft cloth to remove accumulated dirt or grime periodically.

How To Disassemble A Hydraulic Cylinder?

Disassembling a hydraulic cylinder requires careful attention and adherence to proper procedures to ensure safe and effective disassembly. Here is a step-by-step guide on how to disassemble a hydraulic cylinder:

- Preparation and Safety:

- Ensure you have a clean, organized workspace with ample room to work on the hydraulic cylinder.

- Wear appropriate personal protective equipment, including safety glasses, gloves, and protective clothing, to protect yourself from hazards.

- Release Hydraulic Pressure:

- Before disassembling the hydraulic cylinder, release the pressure to avoid sudden movements or accidental activation.

- Open the hydraulic control valve or release the pressure using the appropriate method recommended by the manufacturer.

- Remove External Components:

- Begin by removing external components, such as mounting brackets, clevis pins, or bolts that secure the cylinder to the equipment or machinery.

- Carefully set aside these components in a safe place for reassembly later.

- Remove the Cylinder Cap:

- Locate the cylinder cap, typically at one end of the cylinder.

- Use the appropriate tools, such as wrenches or socket sets, to loosen and remove the bolts or fasteners that secure the cylinder cap.

- Tap the cap to loosen it and carefully remove it from the cylinder.

- Extract the Piston Assembly:

- With the cylinder cap removed, you can access the piston assembly.

- Carefully slide out the piston assembly from the cylinder barrel. It may be necessary to apply gentle pressure or tap the assembly to loosen it.

- Do not damage the piston seals or other components as you remove the assembly.

- Remove the Piston Rod:

- After removing the piston assembly, you can now extract the piston rod.

- Slide the piston rod out of the cylinder barrel, not damaging it or the rod seals.

- If there are any retaining devices or attachments, such as snap rings or bolts, remove them first before attempting to remove the rod.

- Disassemble Additional Components:

- Depending on the hydraulic cylinder’s design, additional components may need to be disassembled.

- Follow the manufacturer’s instructions or guidelines to disassemble any remaining components, such as the gland assembly or rod seals.

- Inspection and Cleaning:

- Inspect all disassembled components for signs of wear, damage, or contamination. Pay special attention to seals, rods, and cylinder walls.

- Clean the components using an appropriate cleaning solution to remove debris, dirt, or old lubricants. Use lint-free cloths or compressed air to dry the pieces thoroughly.

- Replacement or Repair:

- If any components show signs of wear or damage, replace them with new ones from a reputable supplier.

- If necessary, repair or refurbish components as the manufacturer or a qualified professional recommends.

- Reassembly:

- Begin reassembling the hydraulic cylinder by following the reverse order of disassembly.

- Lubricate the seals and other moving parts with a compatible hydraulic fluid or assembly lubricant to aid reassembly and ensure proper functioning.

- Ensure all components are properly aligned and fitted together.

- Tighten all bolts or fasteners to the manufacturer’s recommended torque specifications, ensuring a secure assembly.

- Testing and Reinstallation:

- Once the hydraulic cylinder is reassembled, conduct a thorough inspection to ensure all components are properly aligned and fitted together.

- Reinstall the hydraulic cylinder into the equipment or machinery, following any specific instructions provided by the manufacturer.

- Reconnect the hydraulic lines, ensuring all connections are secure and leak-free.

- Test the hydraulic cylinder for proper function and operation, checking for any leaks, abnormal noises, or other issues during operation.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best light four rod hydraulic cylinder manufacturers. We can offer comprehensive light four rod hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!