HROE aizmugurējā atloka tipa apļveida hidrauliskais cilindrs

Kā viens no hidraulisko cilindru ražotājiem, piegādātājiem un eksportētājiem, mēs piedāvājam hidrauliskos cilindrus un daudzus citus produktus.

Lūdzu, sazinieties ar mums, lai saņemtu sīkāku informāciju.

Pasts:sales@hydraulic-cylinders.net

Hidraulisko cilindru ražotājs, piegādātājs, eksportētājs.

HROE aizmugurējā atloka tipa apļveida hidrauliskais cilindrs

The HROE rear flanged circular hydraulic cylinder is a cutting-edge hydraulic element designed to provide reliable and efficient power transmission for a wide range of industrial applications. With its innovative design and superior performance, this hydraulic cylinder offers precise control, durability, and versatility. Whether in manufacturing, construction, or material handling, the HROE rear flange cylinder optimizes hydraulic operation and increases productivity.

HRO series round cylinder safe and stable, output, easy maintenance, beautiful appearance, high quality, suitable for all kinds of press.

HROA Type Circular Hydraulic Cylinder Characteristic Data:

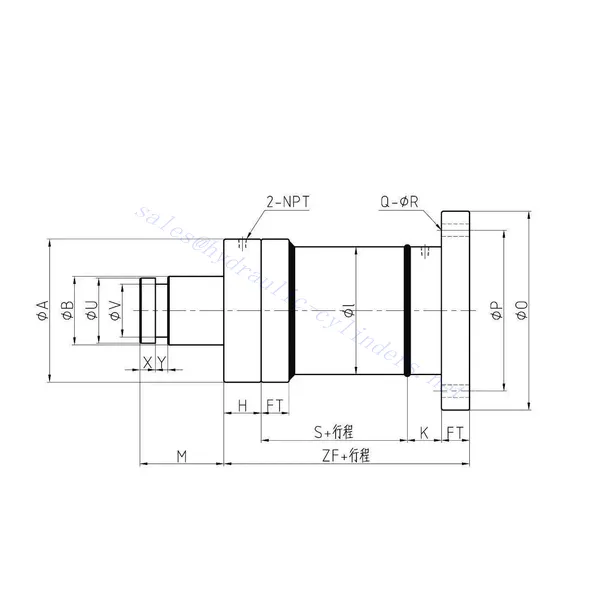

HROA Type Circular Hydraulic Cylinder Structure Diagram:

HROE Rear Flange Type Circular Hydraulic Cylinder Parameter:

HROE aizmugurējā atloka tipa apļveida hidrauliskais cilindrs External Tooth Type Specification Sheet:

HROE aizmugurējā atloka tipa apļveida hidrauliskais cilindrs Usage Method:

- Mounting and Installation:

- Identify the appropriate mounting position for the HROE Rear flange-type cylinder based on the specific requirements of your equipment or machinery.

- Ensure that the mounting surface is sturdy, level, and capable of securely supporting the weight and load of the cylinder.

- Hydraulic System Connection:

- Connect the hydraulic cylinder to the hydraulic system using compatible hydraulic hoses or pipes.

- Ensure proper alignment and secure connections to prevent leaks and ensure optimal performance.

- Operating the Cylinder:

- Activate the hydraulic system to initiate the movement of the HROE Rear Flange Type Cylinder.

- Utilize the hydraulic control system to precisely control the cylinder’s extension, retraction, and positioning for efficient operations.

Characteristics Of HROE Rear Flange Type Circular Hydraulic Cylinder:

- Innovative Design: The HROE rear flange-type cylinder features a state-of-the-art design that maximizes performance, efficiency, and durability.

- Precise Control: This hydraulic cylinder provides superior motion and positioning control, allowing for accurate and efficient operation.

- High Load Capacity: HROE rear flange-type cylinders are designed to handle heavy loads and withstand demanding industrial applications.

- Versatile Applications: The hydraulic cylinder has a universal design, which is suitable for manufacturing, construction, material handling, and other industries.

- Reliability and Durability: HROE rear-flanged cylinders can withstand harsh operating conditions, providing long-lasting performance and minimizing downtime.

- Smooth Operation: The cylinder ensures smooth and reliable operation and minimizes vibration and noise during hydraulic movement.

How To Remove Hydraulic Cylinder From Front End Loader?

Removing a hydraulic cylinder from a front-end loader requires careful preparation and execution. Here’s a step-by-step guide to help you through the process:

- Safety First:

- Before starting work, ensure the front-end loader is parked on a level surface and the engine is turned off.

- Engage the parking brake and place wheel chocks behind the rear wheels to prevent accidental movement.

- Wear appropriate personal protective equipment (PPE), including gloves and safety glasses.

- Identify the Cylinder:

- Locate the hydraulic cylinder you intend to remove. It will be connected to the loader’s hydraulic system and attached to specific mounting points.

- Relieve Hydraulic Pressure:

- To avoid sudden movements or potential injury, relieve the hydraulic pressure in the system before disconnecting the cylinder.

- Start the engine and operate the loader’s hydraulic controls to move the bucket or attachment to a fully extended or raised position.

- Shut off the engine and release any remaining pressure by operating the hydraulic controls a few times.

- Disconnect Hydraulic Connections:

- Locate the hydraulic hoses or lines connected to the cylinder. These are typically secured with fittings, bolts, or quick-release couplings.

- Carefully loosen and disconnect the hydraulic connections, using appropriate tools as needed.

- Be prepared for some hydraulic fluid to leak, so have a catch basin or absorbent material ready to minimize spills.

- Remove Mounting Hardware:

- Identify the mounting points where the cylinder is attached to the loader’s structure. These may include pins, bolts, or brackets.

- Remove any retaining pins or bolts securing the cylinder to the loader using the appropriate tools.

- Keep track of the hardware as you remove it, ensuring it isn’t misplaced or lost.

- Detach the Cylinder:

- With the hydraulic connections and mounting hardware removed, the cylinder should now be free to be detached.

- Carefully slide or maneuver the cylinder out of its mounting position, not damaging any surrounding components or hydraulic lines.

- Use lifting equipment or assistance to handle and remove the cylinder from the loader safely.

- Proper Storage and Maintenance:

- Once the cylinder is removed, inspect it for any signs of damage or wear. Replace any worn-out seals or components, if required.

- Store the hydraulic cylinder in a clean and dry area, protected from dust, moisture, and extreme temperatures.

- If the cylinder requires further servicing, consult the manufacturer’s guidelines or seek professional assistance.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

Mums ir arī pusautomātiska krāsu ražošanas līnija lieliem baloniem, ko darbina ķēdes piedziņa, ar 60 kastu konstrukcijas jaudu vienā maiņā.

(5) Testēšana

Mums ir augstākās klases pārbaudes iekārtas un testēšanas stendi, lai nodrošinātu, ka balona veiktspēja atbilst prasībām.

We are one of the best metallurgical hydraulic cylinder manufacturers. We can offer comprehensive metallurgical hydraulic cylinder stock. We also provide corresponding lauksaimniecības pārnesumkārbas. Mēs esam eksportējuši savus produktus klientiem visā pasaulē un esam ieguvuši labu reputāciju, pateicoties mūsu izcilajai produktu kvalitātei un pēcpārdošanas servisam. Mēs aicinām klientus no valsts un ārvalstīm sazināties ar mums, lai risinātu biznesa sarunas, apmainītos ar informāciju un... sadarboties ar mums!

Dodieties ekskursijā uz mūsu VR rūpnīcu:

Dodieties ekskursijā uz mūsu VR rūpnīcu ar šādiem elementiem.

Hidrauliskā cilindra pielietojums: