V90N-DP Series Axial Piston Variable Displacement Double Hydraulic Pump

Kā viens no hidraulisko cilindru ražotājiem, piegādātājiem un eksportētājiem, mēs piedāvājam hidrauliskos cilindrus un daudzus citus produktus.

Lūdzu, sazinieties ar mums, lai saņemtu sīkāku informāciju.

Pasts:sales@hydraulic-cylinders.net

Hidraulisko cilindru ražotājs, piegādātājs, eksportētājs.

V90N-DP Series Axial Piston Variable Displacement Double Hydraulic Pump

The V90N-DP series axial piston variable displacement double hydraulic pump is a revolutionary solution that combines power, efficiency, and versatility. Designed to meet the demands of modern hydraulic systems, this pump delivers exceptional performance in a wide range of applications. This comprehensive article will delve into the key features, usage methods, and maintenance guidelines for the v90n-dp series axial piston variable displacement double hydraulic pump.

The V90N-DP series axial piston variable displacement double hydraulic pump is a powerful and versatile solution for hydraulic systems. With its dual pump configuration, variable displacement technology, and high-pressure capability, this pump delivers exceptional performance across various industrial applications. By following the recommended usage methods and adhering to regular maintenance practices, the v90n-dp series pump will continue to provide outstanding performance, contributing to the success of hydraulic systems. Embrace the power of versatility and efficiency with the v90n-dp series axial piston variable displacement double hydraulic pump and unlock the full potential of your hydraulic system.

V90N-DP Series Axial Piston Variable Displacement Double Hydraulic Pump Key Characteristics:

- Dual Pump Configuration: The V90N-DP series features a dual pump configuration, integrating two pumps into a single unit. This design maximizes power distribution and enhances overall system performance, making it ideal for applications that require multiple hydraulic functions or simultaneous operations.

- Variable Displacement Technology: Equipped with advanced variable displacement technology, the V90N-DP series pump allows precise adjustment of the output volume for each pump. This feature optimizes energy consumption, reduces heat generation, and enhances the overall efficiency of the hydraulic system.

- High Pressure Capability: With its robust axial piston design, the V90N-DP series pump delivers exceptional performance even under high-pressure conditions. It ensures reliable operation and efficient power transmission, making it suitable for demanding industrial applications.

- Versatile Applications: The V90N-DP series pump is highly versatile and can be used in various industries, including construction, agriculture, material handling, and more. Its adaptability to different working conditions and requirements makes it valuable for diverse hydraulic applications.

V90N-DP Series Axial Piston Variable Displacement Double Hydraulic Pump Parameter:

| Size | V90N180DP | V90N212DP | V90N230DP | V90N252DP | |

| Displacement cc/rev | 180×2 | 212×2 | 230×2 | 252×2 | |

| Rotation r/min | Max for self-priming*1 | 2000 | 1800 | 1800 | 1800 |

| Max*2 | 2400 | 2000 | 2000 | 2000 | |

| Pressure bar | Rated | 380 | 350 | 350 | 350 |

| Peak | 420 | 392 | 392 | 392 | |

| Input torque rating (N.m) | 1200 | 1500 | 1800 | 2100 | |

| Quantity of oil to fill pump case (L) | 10 | ||||

| Suction pressure(bar) | 0.7 ~ 2 | ||||

| Shell pressure(bar) | 1 | ||||

| Max shell pressure(bar) | 3 | ||||

| Weight(kg) | 262 | 270 | 270 | 320 | |

| Oil viscosity (mm2/s) | 10 ~ 1000*3(Best range 16 ~ 36) | ||||

V90N-DP Series Axial Piston Variable Displacement Double Hydraulic Pump Advantages:

• Applied in high pressure open circuit hydraulic systems

• High rated pressure, high efficiency, long life, applied in heavy load conditions

• Flywheel flange interface allows direct connection to PTO

• Compact design, small installation length

• Integrates multiple control methods to perform composite control of pressure, flow and power

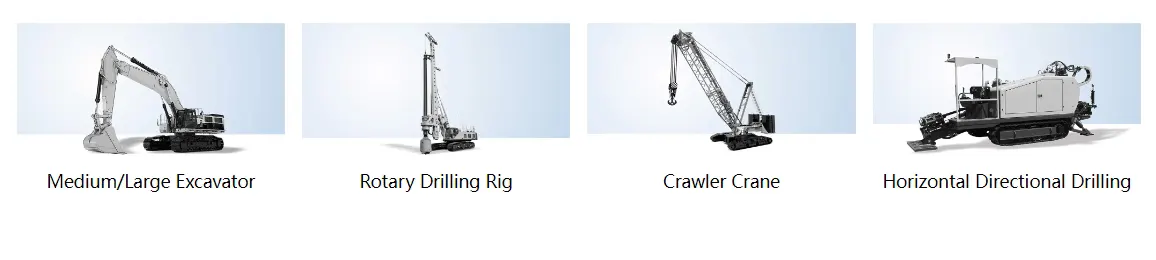

V90N-DP Series Axial Piston Variable Displacement Double Hydraulic Pump Application:

Usage Method Of V90N-DP Series Axial Piston Variable Displacement Double Hydraulic Pump:

- Pump Installation: Select an appropriate location in the hydraulic system to install the V90N-DP Series Axial Piston Variable Displacement Double Hydraulic Pump. Ensure proper alignment and securely attach the pump to the system’s structure using suitable mounting brackets or accessories.

- Integration with Hydraulic System: Connect the pump to the hydraulic system using compatible hoses, fittings, and valves. Ensure all connections are secure, leak-free, and properly tightened to ensure optimal hydraulic performance.

- Fluid Compatibility: Verify that the hydraulic fluid used in the system is compatible with the V90N-DP Series Pump. Refer to the manufacturer’s recommendations for the appropriate fluid type, viscosity, and temperature range. Regularly monitor and maintain the hydraulic fluid to ensure proper pump operation and longevity.

- Operational Parameters: Familiarize yourself with the pump’s control options and adjust the operational parameters according to the specific requirements of the hydraulic system. Monitor and adjust the pump’s displacement settings to optimize performance and energy efficiency.

How To Bleed Hydraulic Cylinder?

Bleeding a hydraulic cylinder is a process used to remove air or gas trapped within the system and ensure proper functioning. Here’s a step-by-step guide on how to bleed a hydraulic cylinder:

- Safety Precautions:

- Ensure the hydraulic system is depressurized and turned off.

- Wear appropriate personal protective equipment, such as gloves and safety glasses.

- Locate Bleeder Valve:

- Identify the bleeder valve on the hydraulic cylinder. It is typically located near the highest point of the cylinder or on the end cap.

- Prepare Tools:

- Gather the necessary tools, including a wrench or socket that fits the bleeder valve.

- Position a Container:

- Place a suitable container or absorbent material beneath the bleeder valve to catch any fluid that may be released during the bleeding process.

- Open Bleeder Valve:

- Slowly and carefully open the bleeder valve counterclockwise using the wrench or socket. This allows air or gas to escape from the cylinder.

- Monitor Fluid Flow:

- Keep an eye on the fluid flow from the bleeder valve. Initially, air or gas may be released, followed by a steady stream of hydraulic fluid. Allow the fluid to flow until all air bubbles are eliminated and only fluid is being expelled.

- Close Bleeder Valve:

- Once only fluid is flowing consistently, close the bleeder valve clockwise. Ensure it is tightened securely, but avoid over-tightening to prevent damage.

- Check Fluid Level:

- Verify the hydraulic fluid level in the system reservoir. If necessary, add fluid to maintain the recommended level.

- Test Cylinder Operation:

- Turn on the hydraulic system and operate the cylinder through its full range of motion. Observe for any abnormalities or irregularities in its movement.

- Repeat if Necessary:

- If there are still signs of air in the system or if the cylinder’s operation is not smooth, repeat the bleeding process. Open the bleeder valve again and allow more fluid to flow until all air is purged.

- Final Check and Maintenance:

- Conduct a final inspection of the hydraulic system for any leaks, proper fluid level, and smooth operation. Address any issues as needed.

- Implement a regular maintenance schedule for the hydraulic system, including periodic checks for air accumulation and bleeding if necessary.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

Mums ir arī pusautomātiska krāsu ražošanas līnija lieliem baloniem, ko darbina ķēdes piedziņa, ar 60 kastu konstrukcijas jaudu vienā maiņā.

(5) Testēšana

Mums ir augstākās klases pārbaudes iekārtas un testēšanas stendi, lai nodrošinātu, ka balona veiktspēja atbilst prasībām.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding lauksaimniecības pārnesumkārbas. Mēs esam eksportējuši savus produktus klientiem visā pasaulē un esam ieguvuši labu reputāciju, pateicoties mūsu izcilajai produktu kvalitātei un pēcpārdošanas servisam. Mēs aicinām klientus no valsts un ārvalstīm sazināties ar mums, lai risinātu biznesa sarunas, apmainītos ar informāciju un... sadarboties ar mums!

Dodieties ekskursijā uz mūsu VR rūpnīcu:

Dodieties ekskursijā uz mūsu VR rūpnīcu ar šādiem elementiem.

Hidrauliskā cilindra pielietojums: