Mobile Machinery

Hydraulic Cylinder

What Is A Mobile Machinery Hydraulic Cylinder?

Mobile machinery hydraulic cylinders are robust, high-performance components designed for the demanding environments of mobile equipment. Engineered for durability, compact design, and high-pressure performance, these hydraulic cylinders for mobile equipment power critical systems in construction, agriculture, mining, and material handling. Whether driving excavators, cranes, or telehandlers, our mobile hydraulic cylinders deliver unmatched reliability and efficiency.

Our mobile equipment hydraulic rams are designed with versatility and customization in mind, offering tailored solutions for specific equipment needs. Whether you require a compact cylinder for a space-constrained tractor or a high-capacity unit for a mobile drilling rig, our mobile machinery hydraulic cylinders can be customized with bespoke stroke lengths, mounting configurations, and load capacities. With advanced sealing technology and low-maintenance designs, our cylinders minimize downtime and reduce operational costs, providing exceptional value for fleet managers, contractors, and equipment manufacturers worldwide

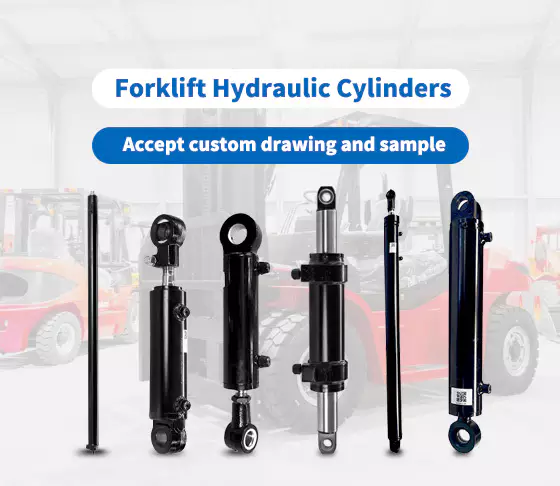

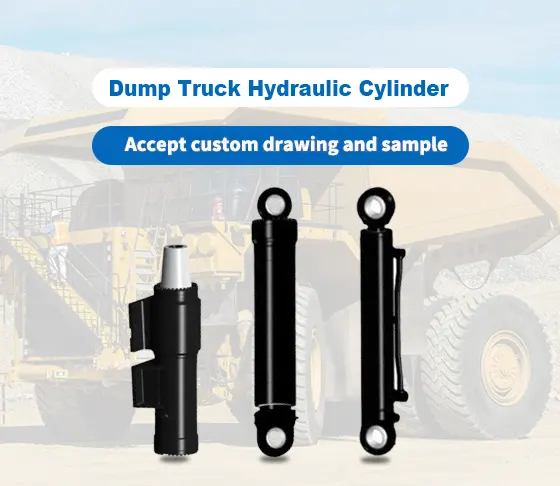

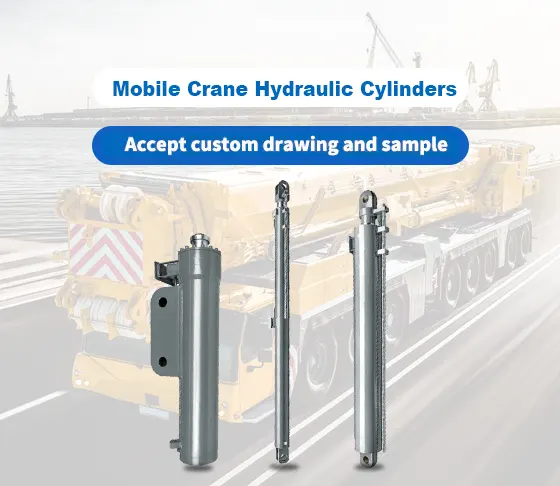

Mobile Machinery Hydraulic Cylinder Types

We also provide other custom hydraulic cylinders for mobile machinery,if you need,please contact us.

Hydraulic Cylinder Production Area

We are a leading manufacturer specializing in hydraulic cylinders and hydraulic systems, dedicated to delivering high-tech solutions. Our company primarily serves OEMs in industries such as construction machinery, aerial work platforms, sanitation vehicles, wind power, and agricultural machinery. We offer a versatile range of hydraulic cylinders with inner diameters ranging from +20 to 500 mm, boasting an impressive annual design capacity of 1.2 million units.

Our state-of-the-art facilities include a provincial research institute, a high-tech R&D center, and a specialized hydraulic product testing laboratory. We utilize advanced equipment such as dedicated turning centers, high-speed cutting and polishing machines, automatic processing and welding systems, automatic cleaning and assembly lines, fully automated flexible painting lines, and intelligent logistics assembly lines. This comprehensive production and testing capability enables us to maintain a strong technological development capacity, ensuring our manufacturing processes and product quality meet advanced national standards.

Visit our VR hydraulic cylinder factory:

Production and Processing Workshop

Loading and Unloading Robots For Paint Lines

Product Testing Center

Cylinder Composite Machining Center

Automatic Cylinder Assembly Machine

With a robust quality assurance system in place, we have achieved ISO 9001 certification for quality management, as well as ISO 45001 for occupational health and safety, and ISO 14001 for environmental management. Our efficient, standardized processes and self-developed high-end equipment guarantee that our hydraulic cylinders are durable, pressure-resistant, leak-proof, and highly stable, with performance metrics that meet international benchmarks.

The “Huachang” series hydraulic cylinders are designed with a focus on structural integrity, reliable performance, and ease of maintenance. Their diverse structural forms allow for tailored solutions to meet specific customer needs. Coupled with our digital production management system, we respond quickly and effectively to customer requirements, ensuring that we exceed your expectations.

Choose us for high-quality hydraulic solutions that enhance your machinery’s performance and reliability.

Cylinder Assembly Line

Special Cylinder Testing Machine

Cylinder Inspection Area

Multi Station Welding Robot

Warehouse

Key Applications of Mobile Machinery Hydraulic Cylinders

Construction Equipment

From excavators to bulldozers, our durable hydraulic cylinders for excavators provide the force needed for digging, lifting, and grading.

Benefit

High-pressure performance for heavy loads.

Use Case

A contractor reduced maintenance costs by 20% with our hydraulic cylinders for construction machinery.

Agricultural Machinery

Our compact hydraulic cylinders for agricultural machinery power tractors, harvesters, and sprayers, offering precision and durability.

Benefit

Compact designs fit small, agile equipment.

Use Case

A farm increased harvest efficiency with our mobile hydraulic cylinders in combine harvesters.

Mining Equipment

Our heavy-duty hydraulic cylinders for mining equipment handle extreme loads in crushers, haul trucks, and drills.

Benefit

Shock-resistant designs for harsh environments.

Use Case

A mining operation extended cylinder life by 30% with our mobile machinery hydraulic cylinders.

Material Handling Equipment

From forklifts to telehandlers, our hydraulic cylinders for material handling equipment ensure smooth lifting and maneuvering.

Benefit

High-precision hydraulics for repetitive tasks.

Use Case

A warehouse optimized load handling with our cost-effective hydraulic cylinders for telehandlers.

Forestry Machinery

Our hydraulic cylinders for forestry machinery power feller bunchers and skidders, designed for rugged terrains.

Benefit

Vibration-resistant for continuous operation.

Use Case

A logging company improved uptime with our mobile hydraulic cylinders.

Mobile Hydraulic Cylinder Maintenance Guide

Extend lifespan and maximize performance for your mobile equipment

Designed for the rigorous demands of mobile machinery in construction, agriculture, mining, and material handling, hydraulic cylinders for mobile equipment require regular care to ensure peak performance, minimize downtime, and prevent costly repairs. Follow these expert tips to keep your mobile machinery hydraulic cylinders reliable, durable, and efficient, whether powering excavators, telehandlers, or forestry equipment.

Inspect Regularly

Regular inspections are essential to detect wear or damage before it escalates. Every three months, thoroughly examine your mobile hydraulic cylinder for signs of leaks, corrosion, or wear on seals, rods, and fittings. These components are critical to the cylinder’s performance and are prone to damage from dust, vibration, and heavy loads in mobile equipment. Use a flashlight to check for micro-cracks or hydraulic fluid residue, and maintain a log to track wear patterns over time.

Clean Thoroughly

Dirt, dust, and debris from mobile machinery environments can accumulate on your mobile hydraulic cylinder, accelerating wear and compromising seals. After heavy use, clean the cylinder with a pressure washer to remove contaminants, ensuring the water pressure is low to avoid damaging seals or coatings. Focus on crevices around rods and fittings, and dry the cylinder with a microfiber cloth to prevent moisture-related corrosion, especially in humid or coastal job sites.

Lubricate Properly

Proper lubrication reduces friction and protects your mobile hydraulic cylinder from wear in high-vibration environments. Use high-performance grease, such as Mobilgrease XHP 222 or Shell Gadus S3 V220C, designed for heavy-duty mobile machinery. Apply grease to rods, seals, and pivot points as per manufacturer specifications, ensuring even coverage without excess, which can attract dirt. Reapply after cleaning or extended operation to maintain a protective barrier.

Monitor Fluid Levels

Clean and adequate hydraulic fluid is vital for the performance of your hydraulic cylinder for mobile equipment. Regularly check fluid levels and quality, ensuring they meet manufacturer specifications (e.g., ISO 32 or 46 hydraulic oil). Look for signs of contamination, such as cloudiness or metal particles, which indicate internal wear or seal failure. Replace contaminated fluid and use high-quality filters to maintain system cleanliness, especially in dusty construction or mining environments.

Schedule Professional Service

Annual maintenance by certified technicians ensures your mobile hydraulic cylinder operates at peak efficiency and prevents major issues. Professionals can conduct pressure tests, replace worn seals, and inspect internal components for wear not visible during routine checks. Schedule service during equipment downtime, such as between construction projects or harvest seasons, and request a detailed report to plan future maintenance. Choose technicians certified by SAE or ISO standards for expertise in mobile machinery.

Why Choose Our Mobile Machinery Hydraulic Cylinders?

Our heavy-duty mobile hydraulic cylinders are engineered to meet the unique challenges of mobile machinery:

Compact Design

Optimized for tight spaces in compact equipment like skid steers.

High Durability

Built to withstand shock, vibration, and extreme temperatures.

Custom Solutions

Tailored for specific applications, from cranes to forestry machines.

Low Maintenance

Advanced seals and coatings reduce wear and downtime.

High-Pressure Performance

Handles pressures up to 6000 PSI for heavy-duty tasks.