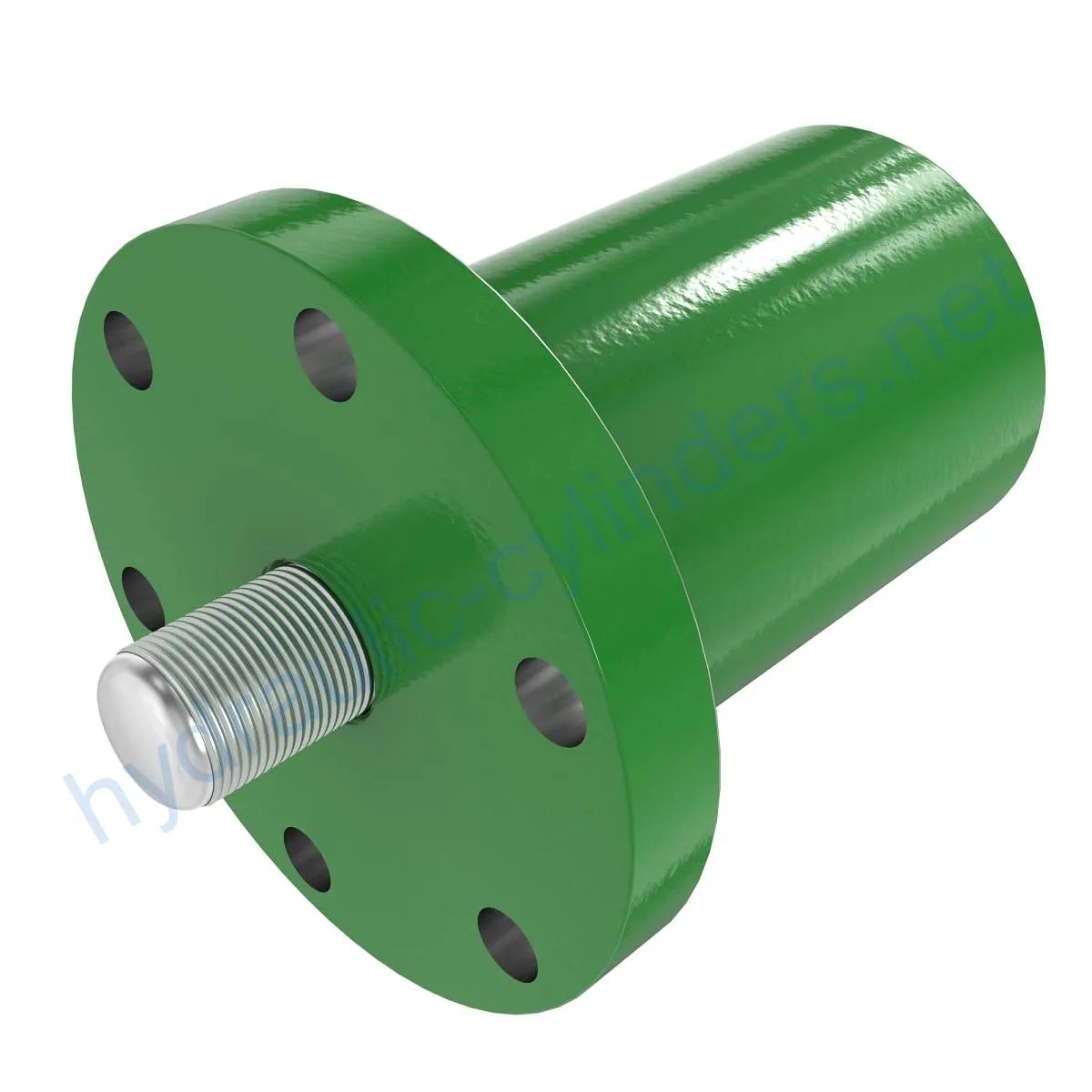

Replacement Of AH169769 Hydraulic Cylinder

Som en av produsentene, leverandørene og eksportørene av mekaniske produkter tilbyr vi hydrauliske sylindere og mange andre produkter.

Ta kontakt med oss for mer informasjon.

Post:sales@hydraulic-cylinders.net

Produsent, leverandør og eksportør av hydrauliske sylindere.

Introduction

The Replacement Of AH169769 Hydraulic Cylinder is a crucial component used in various agricultural and industrial equipment. It is responsible for generating the force needed to operate the machinery.

Specifications and Models

The Replacement Of AH169769 Hydraulic Cylinder weighs 8.6 lb, with a height of 4.3 in and a length of 6 in. It is compatible with several models, including 6620, 7720, 7721, 8820, 9400, 9410, 9450, 9500, 9510, 9540, 9550, 9560, 9580, 9600, 9610, 9640, 9650, 9660, 9660 WTS, 9670, 9680, 9780, C670, CTS, CTS II, T5 400, T5 500, T5 600, T5 700, T6 500, T6 600, T6 700, T6 800, T550, T560, T660, T670, W540, W550, W650, and W660.

Features

- Improved Equipment Performance: Replacing damaged or worn hydraulic cylinders can restore the normal operating capability of the equipment, ensuring its performance in various applications.

- Enhanced Safety: Regularly replacing hydraulic cylinders can reduce safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

- Overload Protection: New cylinder designs typically consider better overload protection mechanisms, enhancing safety.

- Quick Installation: Modern hydraulic cylinders are designed for easy installation and replacement, reducing downtime.

- Standardized Parts: Many hydraulic cylinders are standardized products, making it easy to obtain replacement parts in the market.

Our company offers Replacement Of AH169769 Hydraulic Cylinder that perfectly replaces the original cylinder for all compatible models listed above.

Applications

Hydraulic cylinders are used in various applications, including:

- Excavators: Hydraulic cylinders on the arm or bucket of an excavator can become damaged due to long-term use or overload.

- Cranes: The hydraulic cylinders of the crane’s jib are prone to wear during frequent lifting and lowering cycles, requiring regular replacement to ensure safety.

- Tractors: Hydraulic cylinders of the front-end loader on tractors may leak or experience decreased performance during continuous lifting and tilting operations, requiring replacement.

- Harvesters: Hydraulic systems supports high pressure during harvesting, leading to cylinder fatigue and may require timely replacement to maintain efficiency.

- Automated Production Line: Hydraulic cylinders are used to control robotic arms and other automated equipment. Failure of cylinders can affect production efficiency, requiring immediate replacement.

- Die Casting Machine: Hydraulic cylinders in the die casting machine may experience decreased performance in high-pressure and high-temperature environments, requiring regular replacement to ensure product quality.

- Mining Equipment: Hydraulic cylinders are used in mining equipment to lift and move heavy objects. Due to harsh working conditions, regular inspection and replacement are necessary to avoid equipment failure.

- Bulldozers: The wear of hydraulic cylinders on the bulldozer’s push arm can cause a decrease in pushing capacity, requiring timely replacement to maintain work efficiency.

Maintenance

Proper maintenance is crucial to extend the life of the hydraulic cylinder. Common maintenance tasks include:

- Regular Inspection: Check for signs of wear and tear, leaks, and misalignment, among others.

- Lubrication: Use appropriate hydraulic oil and lubricate the cylinder regularly to prevent friction and wear.

- Seal Replacement: Replace the seals regularly to prevent leaks and maintain the cylinder’s efficiency.

- Calibration Check: Regularly check the cylinder’s calibration to ensure that it meets the equipment’s needs.

Safety and Environmental Considerations

Safety measures are essential when using hydraulic cylinders. Proper installation and maintenance can prevent accidents and unnecessary downtime. It is also crucial to dispose of old hydraulic cylinders in an eco-friendly manner to reduce the environmental impact.

Troubleshooting and Common Issues

Common issues that may arise with the hydraulic cylinder include leaks, misalignment, and worn-out seals, among others. To diagnose and solve such problems, proper maintenance and inspection are necessary. In some cases, it may be necessary to replace the damaged cylinder.

Product Design and Selection Criteria

When selecting a hydraulic cylinder, it is essential to consider its load-bearing capacity, seal quality, durability, safety, and maintainability. Our product is designed with these factors in mind, ensuring optimal performance and reliability.

Seals and Lubrication

Our hydraulic cylinders use various high-quality seals, such as piston seals and rod seals, made of durable, wear-resistant materials such as polyurethane and nitrile rubber. We also recommend periodic lubrication with appropriate hydraulic oil to ensure smooth operation and prevent wear and tear.

Installation Guide

Proper installation is crucial to ensure the hydraulic cylinder’s optimal performance. We provide a detailed installation guide that includes aligning and fixing the cylinder with the appropriate bracket, recommended inspection, repair, and replacement procedures, and tips for extending its service life.

About Our Company

We are a leading manufacturer and wholesaler of hydraulic cylinders, offering a wide range of products that meet international quality standards. We provide customized services, state-of-the-art production equipment, and excellent after-sales support.

Author: lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: