Replacement Of AHC18282 Hydraulic Cylinder

Som en av produsentene, leverandørene og eksportørene av mekaniske produkter tilbyr vi hydrauliske sylindere og mange andre produkter.

Ta kontakt med oss for mer informasjon.

Post:sales@hydraulic-cylinders.net

Produsent, leverandør og eksportør av hydrauliske sylindere.

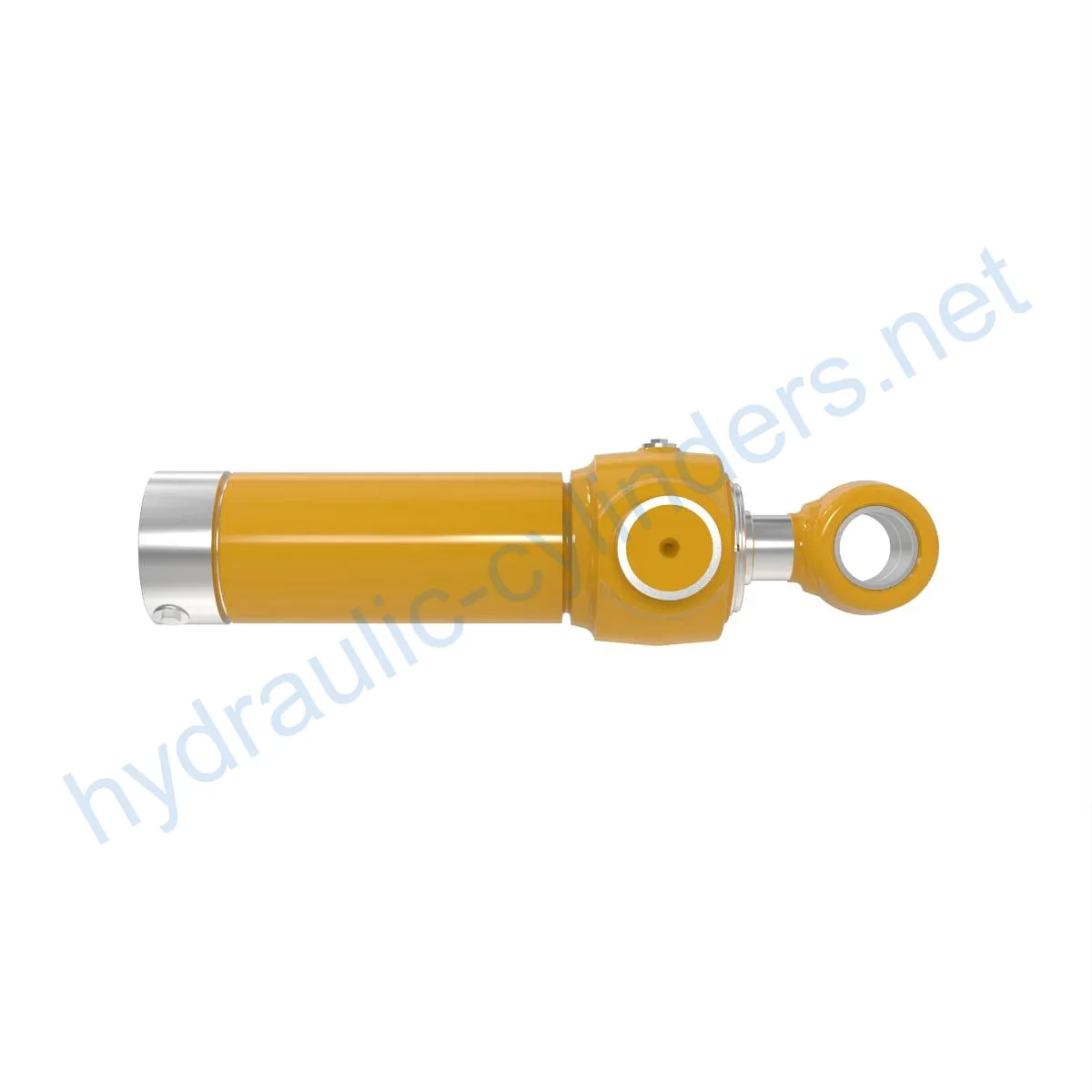

Replacement Of AHC18282 Hydraulic Cylinder

The Replacement Of AHC18282 Hydraulic Cylinder is an essential component used in various machinery and equipment. It serves the purpose of providing hydraulic power to perform mechanical tasks efficiently. This hydraulic cylinder is designed to withstand heavy loads and ensure smooth operation.

Specifications and Models

Specifications:

- Weight: 105.6 lb

- Height: 9.5 in

- Width: 12.5 in

- Length: 27 in

Models:

- 710 P

- 710G

- 710J

- 710K

- 710L

Key Features

1. Improved Equipment Performance

Replacing damaged or worn-out hydraulic cylinders can restore the normal operational capabilities of equipment, ensuring optimal performance in various applications.

2. Enhanced Safety

Regularly replacing hydraulic cylinders can minimize safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

3. Overload Protection

New cylinder designs often include better overload protection mechanisms, improving overall safety during operation.

4. Quick Installation

Modern hydraulic cylinders are designed for easy installation and replacement, reducing downtime and minimizing disruptions to workflow.

5. Standardized Components

Many hydraulic cylinders are standardized, making it easier to source replacement parts in the market.

Applications

1. Excavators

In excavators, the hydraulic cylinder in the arm or bucket may get damaged due to prolonged use or overload, requiring replacement to restore normal operation.

2. Cranes

The hydraulic cylinders in crane boom arms are prone to wear and tear during frequent lifting and lowering processes. Regular replacement is necessary to ensure safety.

3. Tractors

In tractors with front-end loaders, hydraulic cylinder leaks or performance degradation can occur during continuous lifting and tilting operations, demanding replacement.

4. Harvesters

During the harvesting process, hydraulic cylinders in high-pressure systems may suffer fatigue and require timely replacement to maintain work efficiency.

5. Automated Production Lines

Hydraulic cylinders are used to control robotic arms and other automation equipment. Immediate replacement is necessary to avoid disruptions in production efficiency.

Maintenance Tasks

1. Regular Inspection

Periodically inspecting the hydraulic cylinder for any signs of damage or wear is crucial to identify potential issues and prevent major failures.

2. Proper Lubrication

Applying appropriate amounts of hydraulic oil for lubrication ensures smooth operation and extends the lifespan of the hydraulic cylinder.

3. Seal Replacement and Calibration Check

Regularly replacing worn seals and performing calibration checks help maintain optimal performance and prevent leaks or malfunctions.

Safety Considerations and Environmental Factors

When using hydraulic cylinders, it is important to prioritize safety measures to avoid accidents. Proper training, adherence to safety protocols, and regular maintenance are crucial for ensuring safe operation. Additionally, considering environmental factors such as proper disposal of hydraulic fluids and following environmental regulations helps preserve the ecosystem.

Troubleshooting and Common Issues

1. Cylinder Leakage

If there is noticeable fluid leakage from the hydraulic cylinder, it could indicate a seal failure. Check and replace the damaged seals to resolve the issue.

2. Reduced Performance

If the cylinder’s performance decreases, it may be due to wear or internal damage. Proper inspection and replacement of necessary components can restore optimal performance.

3. Slow or Inconsistent Operation

If the hydraulic cylinder operates slowly or inconsistently, it may be a result of insufficient lubrication or a damaged piston. Lubricate properly or replace the piston to rectify the problem.

4. Unusual Noises

Unusual noises during cylinder operation can indicate mechanical issues or misalignment. Inspect and address the source of the noise to prevent further damage.

Product Design Considerations and Selection Criteria

When selecting hydraulic cylinders, several design considerations should be taken into account:

1. Load-Bearing Capacity

The hydraulic cylinder should have the appropriate load-bearing capacity to handle the intended workload without strain or failure.

2. Sealing and Durability

Choosing hydraulic cylinders with high-quality seals and durable materials ensures longevity and minimizes the risk of leaks or premature failure.

3. Safety Features

Hydraulic cylinders with built-in safety features, such as overload protection mechanisms or emergency stop functions, enhance operational safety.

4. Maintenance and Repairability

Opt for hydraulic cylinders that are designed for easy maintenance and repair, with readily available replacement parts and rebuild services.

Proper Seal and Lubrication

Hydraulic cylinders utilize various seals, including piston seals and rod seals, made from wear-resistant materials such as polyurethane or nitrile rubber. The cylinder body and threaded ends undergo precise surface treatments to enhance wear resistance. Regular lubrication with the appropriate amount of hydraulic oil ensures optimal performance and reduces friction.

Regular Inspection and Preventive Measures

Regularly inspecting hydraulic cylinders for wear, leaks, or misalignment helps identify potential issues before they escalate. Proper installation techniques, alignment guidance during installation, and the use of suitable mounting brackets for secure cylinder fixation are crucial. Recommended inspection, repair, and replacement procedures should be followed to ensure maximum lifespan. Tips to prolong the lifespan of hydraulic cylinders include employing proper usage techniques and adhering to recommended maintenance schedules.

About Our Company

We are a leading manufacturer and wholesale distributor of replacement hydraulic cylinders, offering a comprehensive range of products. Our company is known for its professionalism, international certifications, customized services, state-of-the-art production equipment, and exceptional after-sales support.

Author: lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

Hydraulic Cylinder Application: